MATERIALE PLASTICE ȘI CAUCIUC

Ce se gǎsește în categoria Materiale plastice și cauciuc?

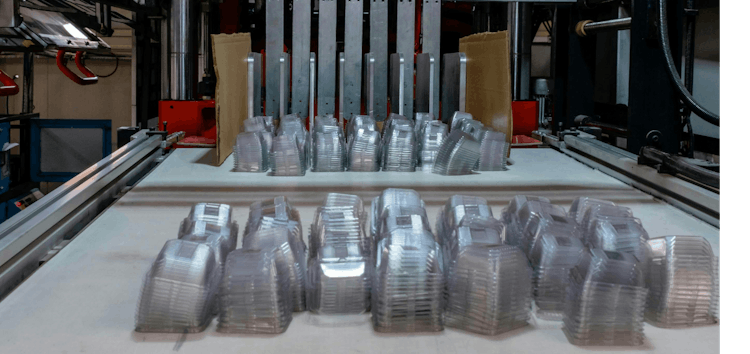

Categoria Materiale plastice și cauciuc include mașini de suflare prin extrudare, extrudoare, bobinatoare pentru film, granulatoare, mașini de injecat mase plastice, laminatoare, mașini pelețiatoare, mori pentru plastic și cauciuc, linii de producție pentru plastic, utilaje pentru prelucrarea cauciucului, mașini de termoformare, aparate de sudurǎ cu ultrasunete, mașini de termoformare în vid.

Echipamente pentru fabricarea plasticului și cauciucului disponibile în prezent

Filtering

(Showing 39 of 39 items)

- ViewKang Chyau KMT-55CE HDPE/LDPE Blown Film Extrusion Line (2004)Blown Film (HDPE / LDPE / LLDPE) Production Line, Comprising Of The Following Main Components, Extruder: Screw Ø 55 mm, L/D 30:1, AC 25 HP Motor With Inverter. Die Head Ø 150 mm, Air Ring Ø 150 / 200 / 230 mm, Cooling Blower: 5 HP With Inve...

- ViewGÜR-İŞ MAKINA BS 1100 WL Bottom-Sealing Bag Machine (2000)Automatic Bag Making Line (Bottom Seal, Stacking, Perforation), Comprising Of The Following Main Components, Automatic Unwinder: With Pneumatic Shaft. Bottom Sealing And Cutting Unit: Hot Knife. Perforation And Photo-Cell Synchronization. C...

- View2 Lines Of Plastic Densifiers with Platform and Control CabinetAgglomerator / Densifier System (Frictional, 2 Units) No. Of Units: 2. Working Principle: Frictional Densification With Rotating Blades And Water Dosing. Bowl Inner Diameter: 700 mm Each. Bowl Height: 1.000 mm, Discharge: Manual Bottom Outl...

- ViewWS BA 2 Extruder Blow Moulding Machine for Jerry Cans/Bottles (1980)Extrusion Blow Moulding (EBM) Machine, Comprising Of The Following Main Components, Hopper And Screw Extruder. Parison Extrusion Head. Hydraulic Mould Clamping System. Downstream & Auxiliary Equipment: Cooling Circuit, Control Cabinet, Acce...

- ViewHandle Punching Machine for T-Shirt BagsPneumatic Handle Punching Press, Function: Cutting Carrying Handles (Die-Cut) In T-Shirt Bags After Bottom Sealing. Operation: Pneumatic, With Single Cutting Die. Existing Die Size: 110 × 120 mm, Integrated Electrical Cabinet With Emergenc...

- ViewARVOR Perfo BF/NP 03 Bag-Making Machine (2007)Bag Making/Converting Line (Thermal Cutting And Sealing), Input Section: Double Unwinder For Two Tracks. Film Roll Width: Max 1.400 mm. Downstream & Auxiliary Equipment: Process: Thermal Cutting And Sealing, With Ballet-Type Outfeed System ...

- ViewCDM Engineering ES-105 Plastic Pelletizing Line (2012)Plastic Compounding / Pelletizing Line (Single Screw, Degassing), Comprising Of The Following Main Components, Single-Screw Extruder: Screw Ø105 mm, With Degassing And Screen Changer. Granulation Head: Diameter Approx. 150–180 mm (Based On ...

- ViewTRIA 60-42 XT Plastic Granulator/GrinderGranulator/Grinder Machine (High Speed Rotor), Comprising Of The Following Main Components, Hopper Opening: 620 × 420 mm. Rotor Diameter: 360 mm. Blades: 3 Rotor + 2 Fixed (Optionally 5 + 2). Motor: 30 kW (Electro Adda EG200L-4). Downstream...

- ViewIVR SAR50 R Film Rewinder/Unwinder Unit (2000)Compact Film Winding Unit (Rewinder/Converter), Function: Used For Rewinding Or Converting Large Rolls Into Smaller Rolls. Adaptability: Adaptable For Cores Of Ø 76 mm And Ø 40 mm. Downstream & Auxiliary Equipment: Control Cabinet: Integrat...

- ViewAMIS Machinen-Vertriebs GmbH / Zerma Complete Plastic Film Washing and Granulation Line(2006)Plastic Washing And Granulating Line (Zerma / Friction Washer), Comprising Of The Following Main Components, Zerma Granulator GS 400/600: Rotor Ø 400 mm × Width 600 mm, Rotor Knives: 3 × 2, Bed Knives: 2, Rotor Speed: 650 rpm. Friction Wash...

- ViewLEMO ROLLOMAT 850 Machinenbau GmbH Bag-on-Roll LineFilm Converting/Rewinding Line (2 Lanes, Pneumatic Unwinder), Comprising Of The Following Main Components, Film Unwinder: With Pneumatic Shaft. Folding And Gusseting Unit. Sealing And Perforation Section. Downstream & Auxiliary Equipment: A...

- ViewKang Chyau KMT-55CE LDPE Blown Film Extrusion Line (2016)Mono-layer Blown Film (LDPE) Production Line, Comprising Of The Following Main Components, Extruder: Screw Ø 55 mm, L/D 30:1. Blower Unit Ø 100 mm, Air Ring Diameter 120/145mm, Electrical Cabinet (Free-Standing Control Panel), Corona Treatm...

- ViewUstun Is Makina Complete Agglomeration and Drying Unit (2010)Agglomeration / Densification System (USM AG90, 90 kW Main Drive), Comprising Of The Following Main Components, Agglomerator: Model USM AG90 101, Year 2010, Chamber Ø ≈ 1.000 mm, Heavy-Duty Friction Compactor Type. Feeding Silo: Rectangular...

- ViewTRIA S.p.A LCE Series Laboratory / Small Plastic GranulatorSlow Speed Granulator / Edge Trimmer Grinder, Comprising Of The Following Main Components, Drive Motor: BONFIGLIOLI M2SB4 – 1.1 kW / 1.390 rpm. Gearbox: BONFIGLIOLI A41 2 UH45 S2, Ratio 53.1:1 (Built 11/2007). Cutting Chamber Width: ~200 mm...

- ViewHANGLI, Type YYJ Meter, Counting and Printing UnitFeed System: Mechanical Wheel Feed System With Two Measuring Rollers. Control Unit: Integrated Control And Heating Stand: Adjustable Height Stand On Four Feet, Certification: CE Marking.

- ViewTEANKA Dual-Station Plastic Bobbin Winder (2005)Slitting And Winding Unit (Dual Shaft), Comprising Of The Following Main Components, Winding Shafts: Two Independent Winding Shafts With Adjustable Arms. Control Panel: Central Electronic Control Panel With Digital Speed And Tension Control...

- ViewPlastic Washing and Separation System “David Harrison / PolyWashPlastic Washing / Pre-Treatment System (High-Efficiency Mechanical Washing), Comprising Of The Following Main Components, Main Washing Tank: With Paddle Shaft And Agitation System (Visible Paddles For Efficient Friction Cleaning). Rotating ...

- ViewIPTE AFS 5 Blow Moulding Machine (1984)Extrusion Blow Moulding (EBM) Machine (2–5 Litre Capacity), Comprising Of The Following Main Components, Extruder Type: Single Screw. Mould Clamping Unit: Hydraulic, 2 Halves. Downstream & Auxiliary Equipment: Control System: Relay-Type Ele...

- ViewGÜR-İŞ MAKINA HS-1000P + DD700 T-Shirt Bag Making Line (2006)T-Shirt Bag Making Line (Two Tracks, Hydraulic Punching), Comprising Of The Following Main Components, Film Unwinder: With Pneumatic Shaft. Hot Knife Longitudinal Cutter: Splitting 1.100 mm Film Into 2 Tracks. Cutting And Bottom Sealing Sta...

- ViewKang Chyau KMH-55CE HDPE/MDPE Blown Film Extrusion Line (2015)Blown Film (HDPE / MDPE) Production Line, Comprising Of The Following Main Components, Extruder: Screw Ø 55 mm, L/D Ratio 32:1, AC 25 HP Motor With Inverter. Die Head Ø 100 mm, Air Ring Ø 180 / 230 mm, Cooling Blower: 5 HP With Inverter. Do...

- ViewFeed Section with Crusher and Material Hopper (2000)Pre-Processing / Granulating Unit (Integrated System), Comprising Of The Following Main Components, Compact Granulator/Crusher: With Side Discharge. Drive: Driven By Electric Motor Via Gearbox, Metal Feeding Hopper: With Inclined Auger Conv...

- ViewMANNESMANN DEMAG D 60-275 NCIII-S Injection Moulding Machine (1992)Injection Moulding Machine (IMM) (275 Ton Clamping Force), Comprising Of The Following Main Components, Clamping Force: 2.750 kN (≈ 275 Tons). Screw Diameter: 60 mm. Downstream & Auxiliary Equipment: Control System: NCIII-S. Technical Data ...

- ViewPlastic Granulator/CrusherGranulator / Crusher (Belt-Driven Rotor), Comprising Of The Following Main Components, Rotor Type: Open, Multi-Knife Configuration (Exact Number Not Visible). Feed Opening: 500 × 500 mm, Construction: Steel Frame With Belt-Driven Rotor, Sid...

- ViewHEMINGSTONE JP-32SE-SV-AM Bottom-Seal & Courier-Bag Making Machine (2016)Automatic Bag Making Line (Perforation And Seal-Strip Application), Functions: Bottom Sealing, Film Perforation, Adhesive-Tape (Seal-Strip) Application Unit. Perforation System: 6 mm Holes. Downstream & Auxiliary Equipment: Control System: ...

- ViewMANNESMANN DEMAG D 500-4500 NCIII-S Injection Moulding Machine (1993)Injection Moulding Machine (IMM) (450 Ton Clamping Force), Comprising Of The Following Main Components, Clamping Force: 4.500 kN (≈ 450 Tons). Screw Diameter: 100 mm (Approx.). Downstream & Auxiliary Equipment: Control System: NCIII-S (Digi...

- ViewLEMO-INTERMAT 2 T-Shirt Bag Making LineT-Shirt Bag Making Line, Comprising Of The Following Main Components, Unwinder: For Tubular Or Folded Film. Longitudinal Cutting Section: With 2 Knives (Splitting Into 3 Lanes). Longitudinal Welding Unit. Folding Station: With 4 Folds (Left...

- ViewGÜR-İŞ TY 850 Side-Weld Bag-Making Machine (2012)Side-Sealing Bag Making Line (Folded-Bottom Formation), Operation: Side-Sealing With Folded-Bottom Formation System. Perforation System: 6 mm Diameter Holes. Downstream & Auxiliary Equipment: Output Type: Flat Or Gusseted Bags With Side Wel...

- ViewBlow Moulding Machine for Large ContainersExtrusion Blow Moulding (EBM) Machine (10 Litre, Accumulator Head), Comprising Of The Following Main Components, Extruder Type: Single Screw With Accumulator Head. Mould Clamping System: Hydraulic. Downstream & Auxiliary Equipment: Typical ...

- ViewKang Chyau KMT-45CE HDPE/LDPE Blown Film Extrusion Line (2014)Blown Film (HDPE / LDPE / LLDPE) Production Line, Comprising Of The Following Main Components, Extruder: Screw Ø 45 mm, L/D 32:1, AC 20 HP Motor With Inverter. Die Head Ø 70 mm, Air Ring Ø 120 mm, Cooling Blower: 3 HP With Inverter. Downstr...

- ViewMANNESMANN DEMAG D 300-1190 NCIII Injection Moulding Machine (1988)Injection Moulding Machine (IMM) (300 Ton Clamping Force), Comprising Of The Following Main Components, Clamping Force: 300 Tons. Injection Capacity: 1.190 cm³. Downstream & Auxiliary Equipment: Control: NCIII (Numerical Control Generation ...

- ViewLow Density Polypropylene (LDPE) Film Production LineHigh Capacity Blown Film (LDPE) Production Line, Comprising Of The Following Main Components, Extruder A - Bieloni: Screw Equipped With MSM Gravimetric Dosing Unit, Extruder B - Bieloni: Equipped With MSM Gravimetric Dosing Unit, Extruder C...

- ViewKang Chyau KML-65S CE LDPE/LLDPE Blown Film Extrusion Line (2016)Blown Film (LDPE / LLDPE) Production Line, Comprising Of The Following Main Components, Extruder: Screw Ø 65 mm, L/D 32:1, AC 60 HP Motor With Inverter. Die Head Ø 200 mm, Air Ring Ø 230 mm, Cooling Blower: 7.5 HP With Inverter, Dosing Unit...

- ViewCGA Hollowwrap Type 231-008 Core Cutting & Finishing Machine (2012)Core Cutting/Finishing Machine (Semi-Automatic), Operating System: Semi-Automatic With Control Panel. Functions: Adjustable Cutting Path (Short / Long), Core Feeding, Precision Cut & Output Tray. Downstream & Auxiliary Equipment: Constructi...

- ViewTRIA 60-42 XT Plastic Granulator/GrinderGranulator/Grinder Machine (High Speed Rotor), Comprising Of The Following Main Components, Hopper Opening: 620 × 420 mm. Rotor Diameter: 360 mm. Blades: 3 Rotor + 2 Fixed (Optionally 5 + 2). Motor: 30 kW (Electro Adda EG200L-4). Downstream...

- ViewTRIA 60-42 XT Plastic Granulator/GrinderGranulator/Grinder Machine (High Speed Rotor), Comprising Of The Following Main Components, Hopper Opening: 620 × 420 mm. Rotor Diameter: 360 mm. Blades: 3 Rotor + 2 Fixed (Optionally 5 + 2). Motor: 30 kW (Electro Adda EG200L-4). Downstream...

- ViewUstunIsMakina USM KNS300 Plastic Dewatering/Squeezing Line with Bexmac Drive and Electrical Cabinet (2023)Squeezing / Dewatering Press (Conical Screw), Comprising Of The Following Main Components, Press Body: UstunIsMakina USM KNS300 With Conical Squeezing Screw. Drive Motor: High-Torque BEXMAC Assembly. Gearbox: Yilmaz Reduktor Type LTE0823.0X...

- ViewAKDEMİR AK1-200 Roll Rewinder with Perforation (for Heavy-Duty Film Rolls) (2013)Heavy-Duty Film Rewinding Unit (Integrated Perforation System), Main Function: Heavy-Duty Film Rewinding Unit For Thick Polyethylene Sheets Or Tubular Film. Perforation System: Integrated Perforation System For Roll-To-Roll Separation. Down...

- View3 MEP 60/1200 Film Extrusion LinesSet of three mono-layer polyethylene blown-film extrusion lines, Comprising Of The Following Main Components, Extruder: Estimated Screw Ø 60 mm. Die Head: Approx. Ø 180 mm (Single-Layer). Air Ring & Tower: Standard Single-Blower Design. Dow...

- ViewLemo Maschinenbau GMBH Automatic Bag making Line (1993)Automatic Line For Production Of Plastic Bags (Servo Drive, Web Guiding System), Comprising Of The Following Main Components, Unwinder: For Tubular Or Folded Film. Longitudinal Cutting Section: With 2 Knives (Splitting Into 3 Lanes). Longit...

Producători

Producătorii care se găsesc în mod normal în această categorie sunt Arburg, Battenfeld, Borche, Boy, Cincinnati, Demag, Desma, Dima, Engel, Husky, Jomar, Krauss Maffei, Mag Plastics, Milacron, Mitsubishi, Multitech, Nan, Neff, Negri Bossi, Newbury, Niigata, Nissei, Sumitomo, Toshiba, UBE, UMS.