Plastic Bag Manufacturing Facility – Available Due to Site Closure

Starts: 03 December 2025 at 08:00 GMT

Ends: 25 February 2026 at 13:00 GMT

Please see the sale information section for any additional fees that may be applicable upon purchasing an item. NOTE: Invoicing of top winning bids is subject to allocation.

Share:

Showing 48 of 48 lots

- LOT 1

![site]()

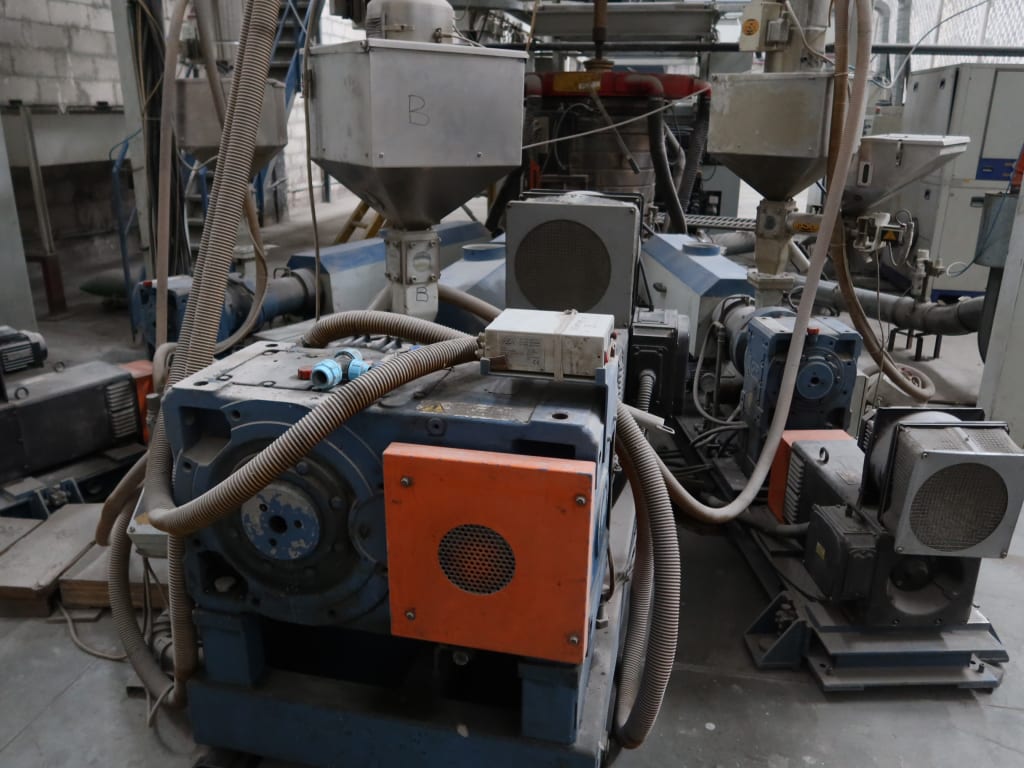

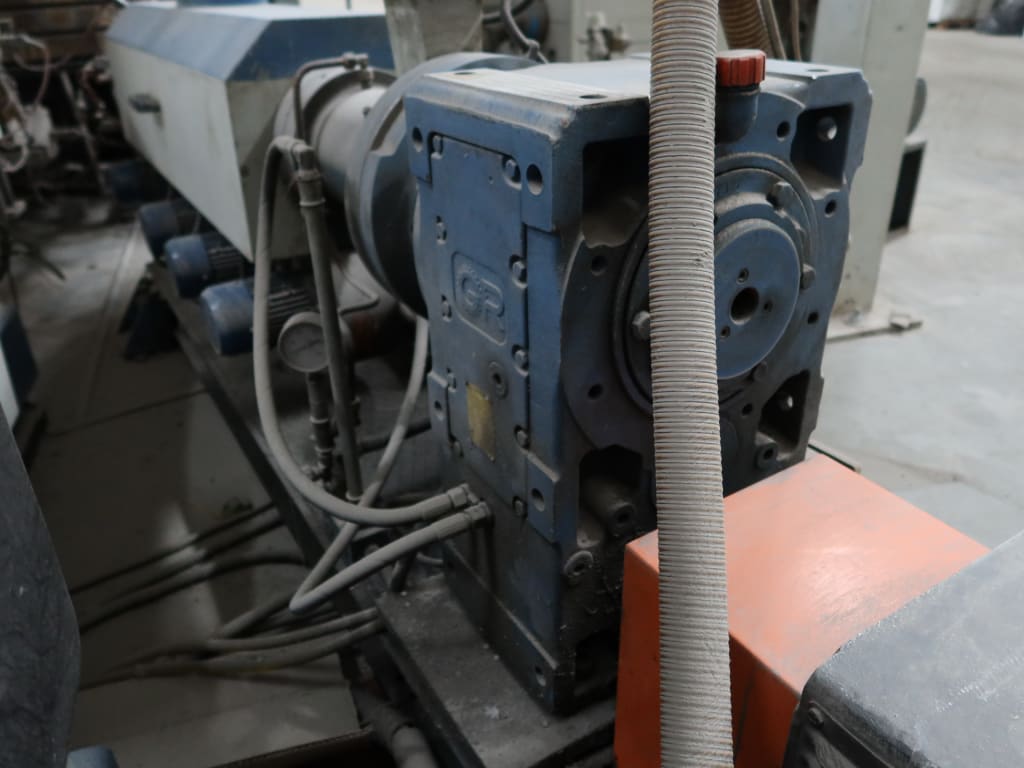

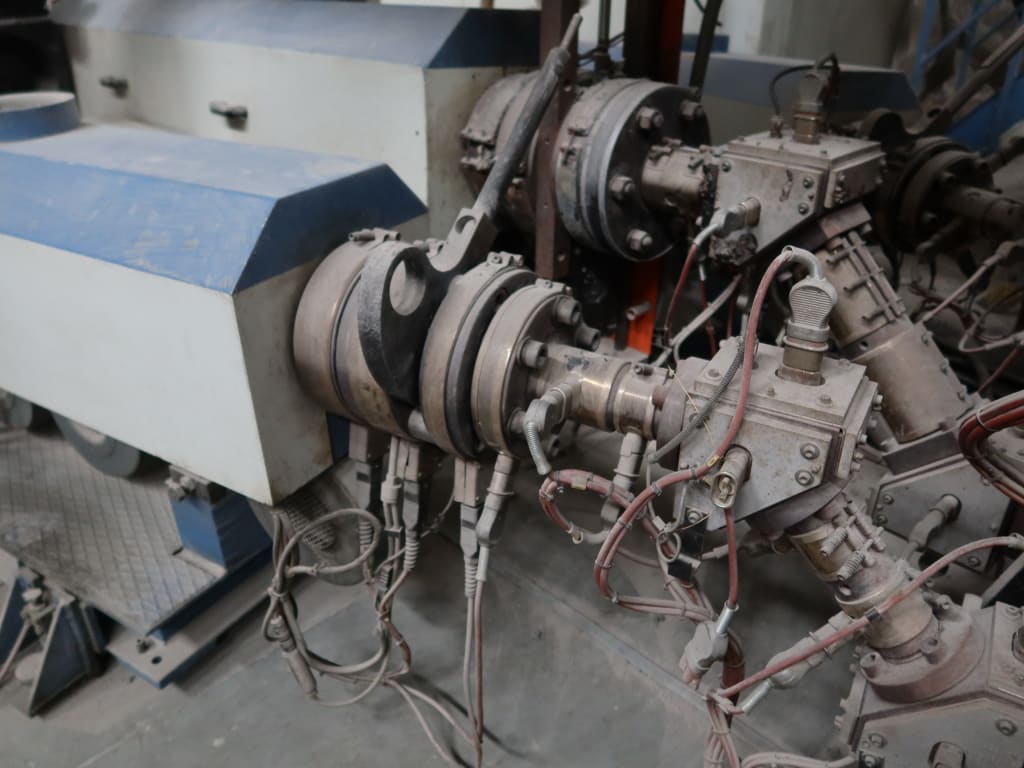

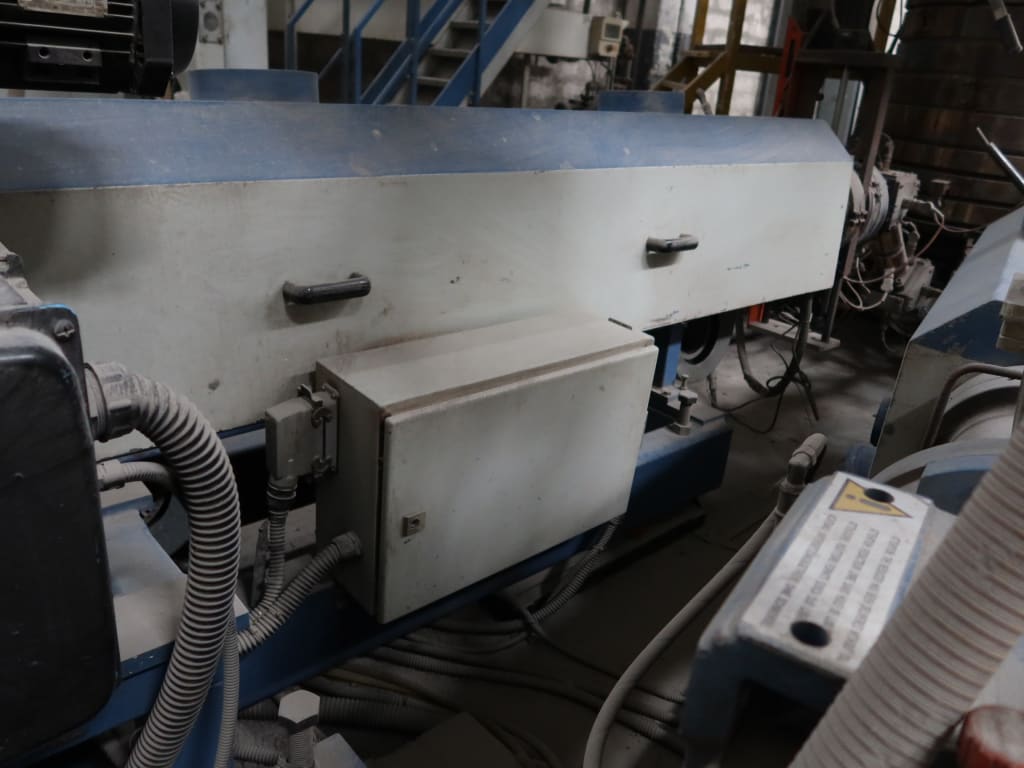

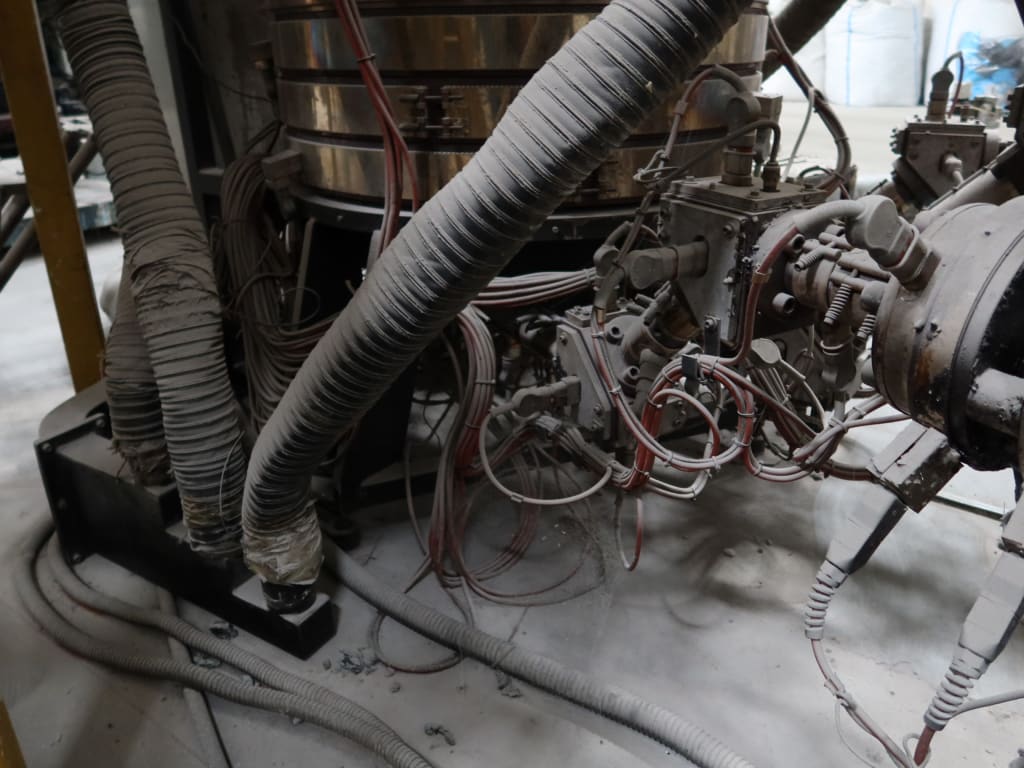

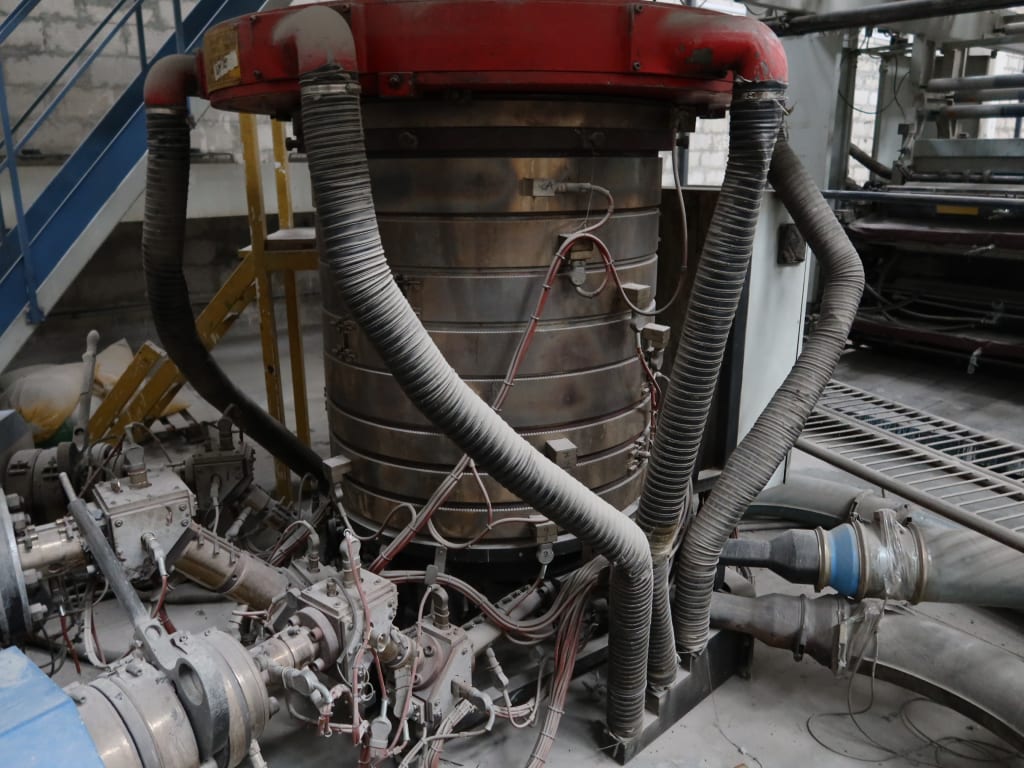

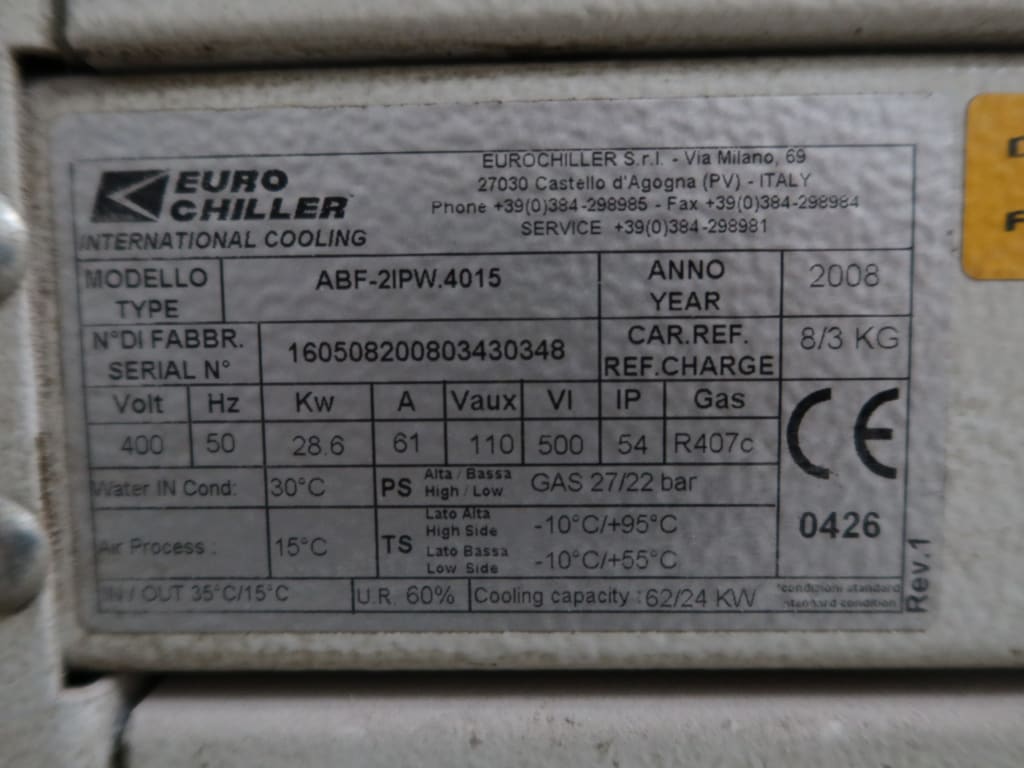

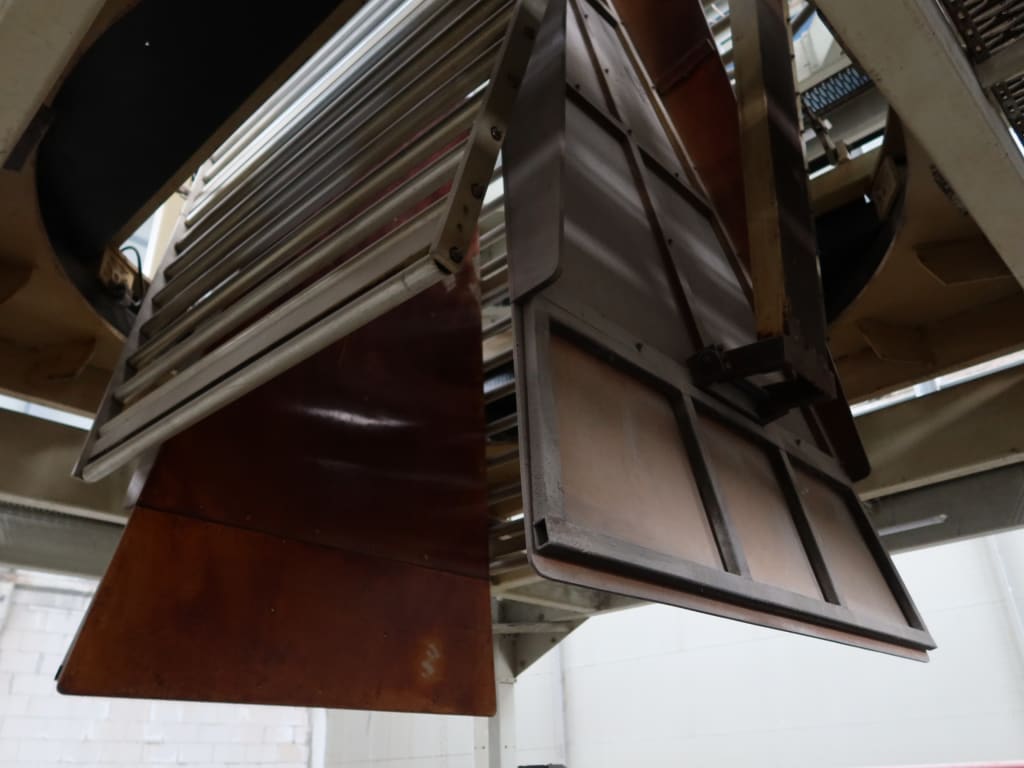

Low Density Polypropylene (LDPE) Film Production Line

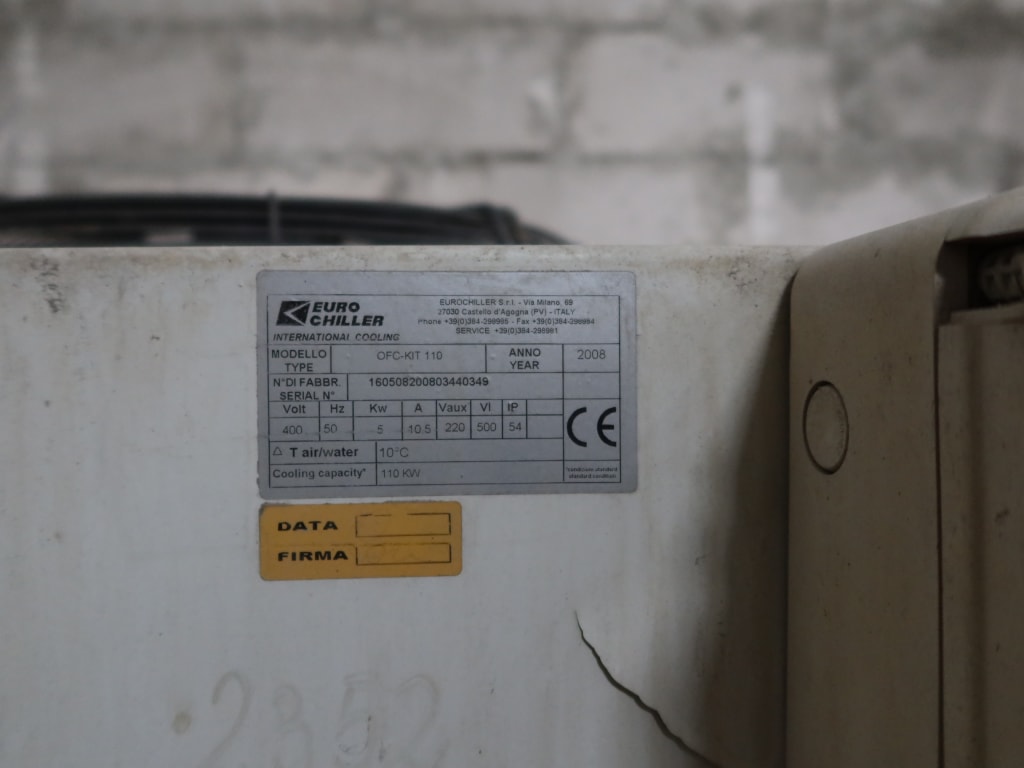

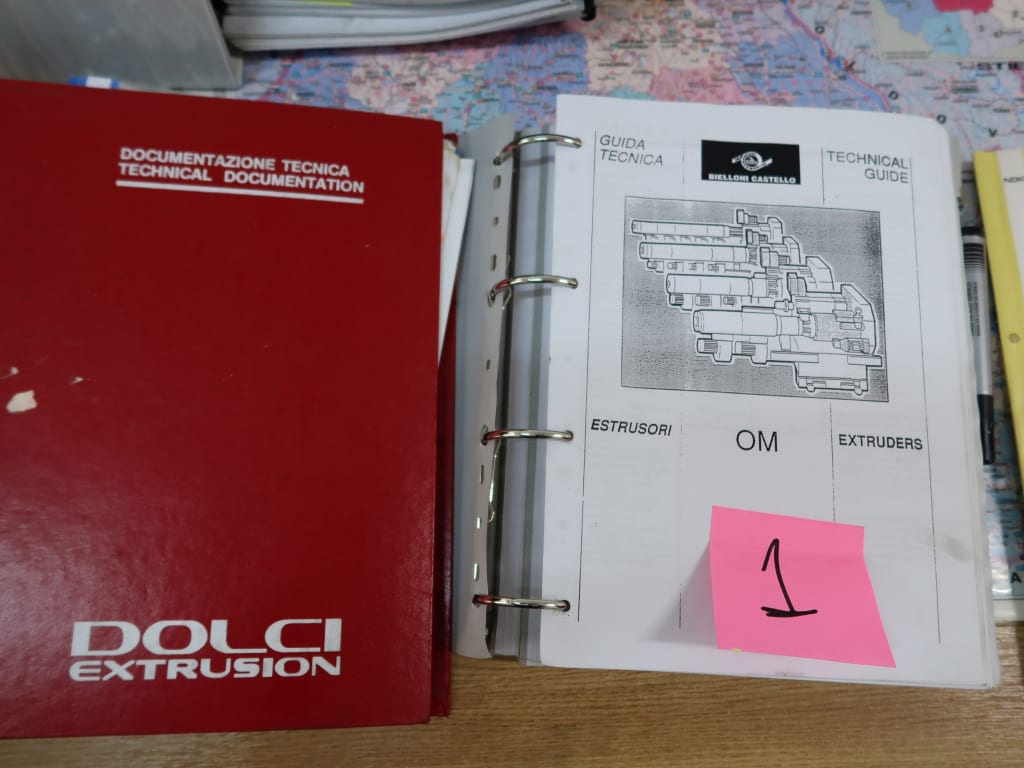

High Capacity Blown Film (LDPE) Production Line, Comprising Of The Following Main Components, Extruder A - Bieloni: Screw Equipped With MSM Gravimetric Dosing Unit, Extruder B - Bieloni: Equipped With MSM Gravimetric Dosing Unit, Extruder C - Bieloni: Screw Equipped With MSM Gravimetric Dosing Unit. Blower Unit DOLCI, Ø400mm (Includes Spare Blower Ø600mm). Downstream & Auxiliary Equipment: Printing Unit, 4 Colours (3 Currently Installed), Corona Treatment Unit, Cooling Unit EURO CHILLER, 110kW (Year 2008). Technical Data (Approx.): Film Thickness: 75–200μm, Maximum Film Width: 6,000mm (Flat) Or 1,840mm (Folded). Maximum Printing Width: 1,600mm. Overall Dimensions: L18,500 × W11,500 × H13,000mm. Metal Supporting Frame: 4,700 × 4,700 × 11,000mm. - LOT 2

![site]()

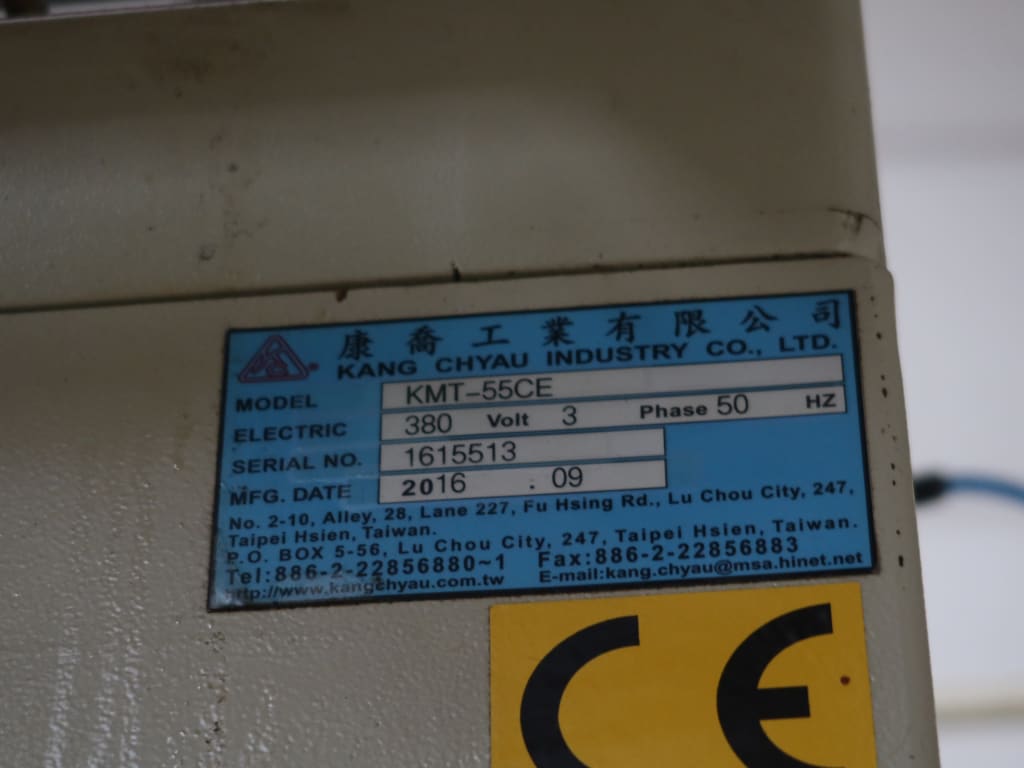

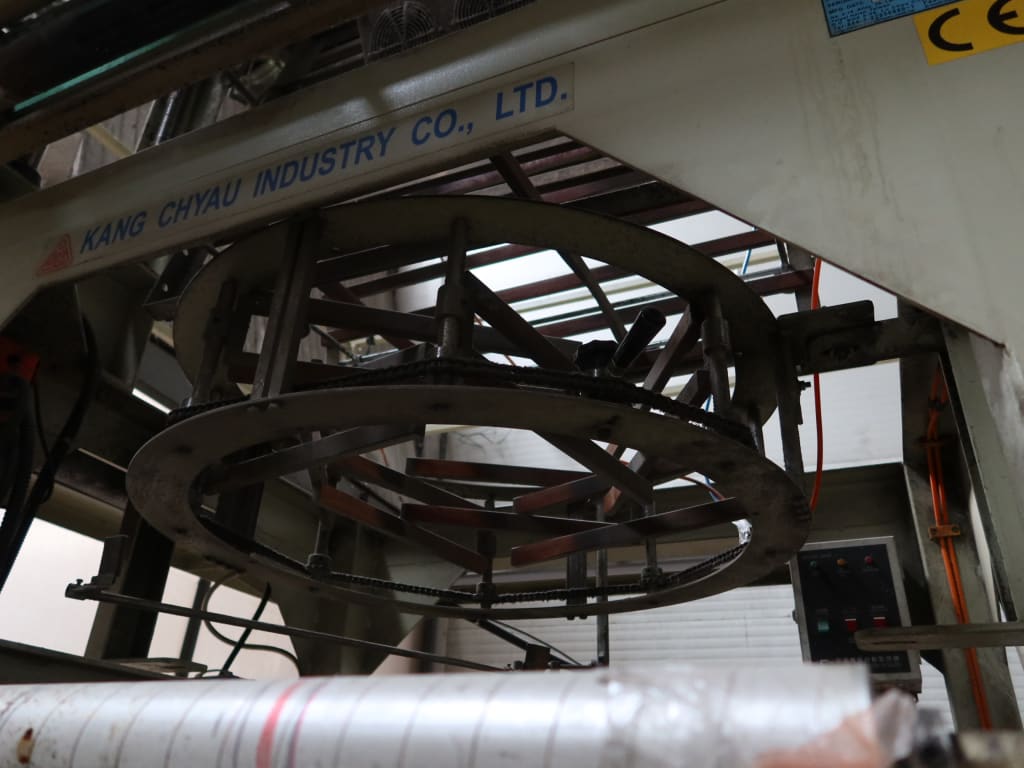

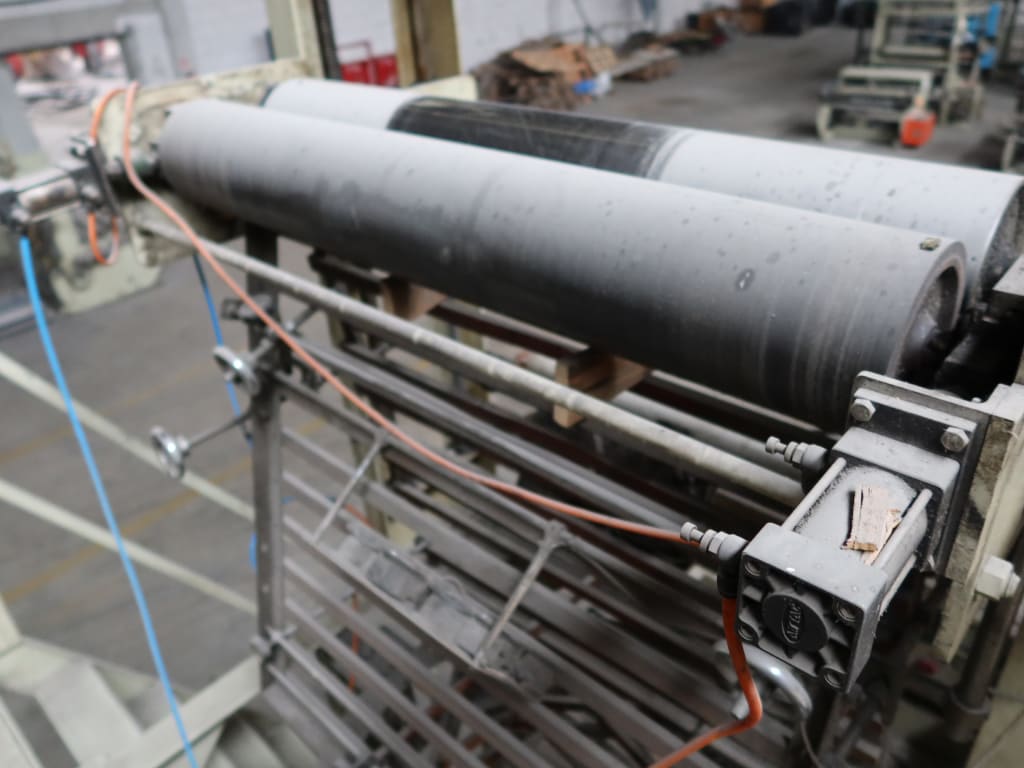

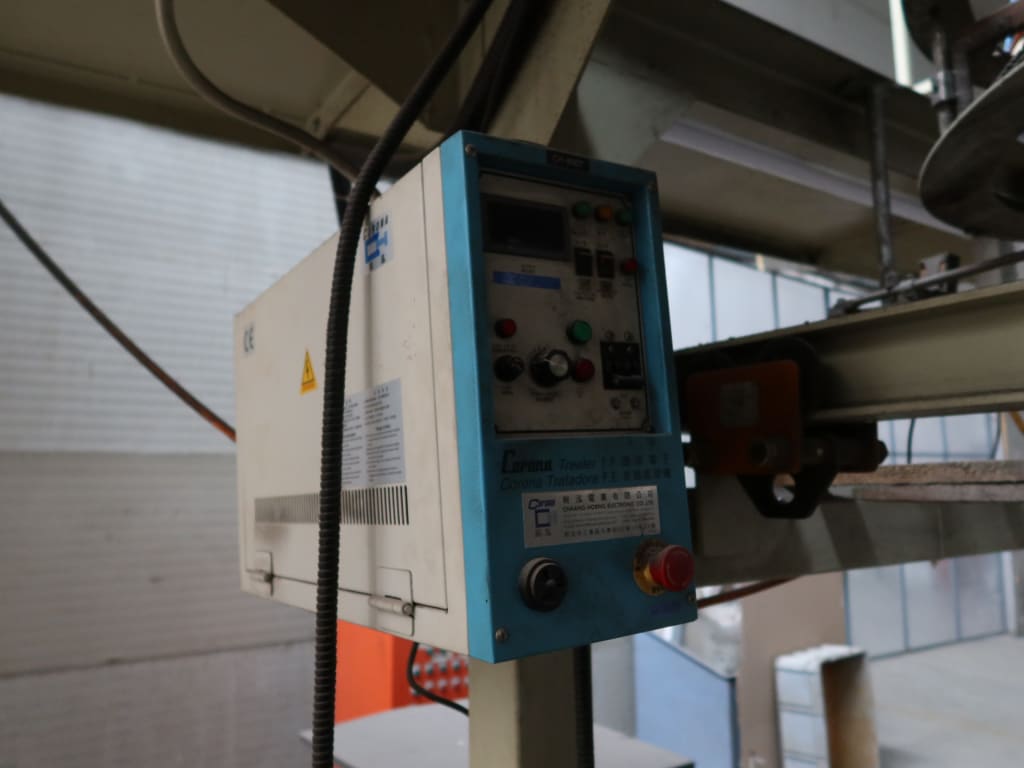

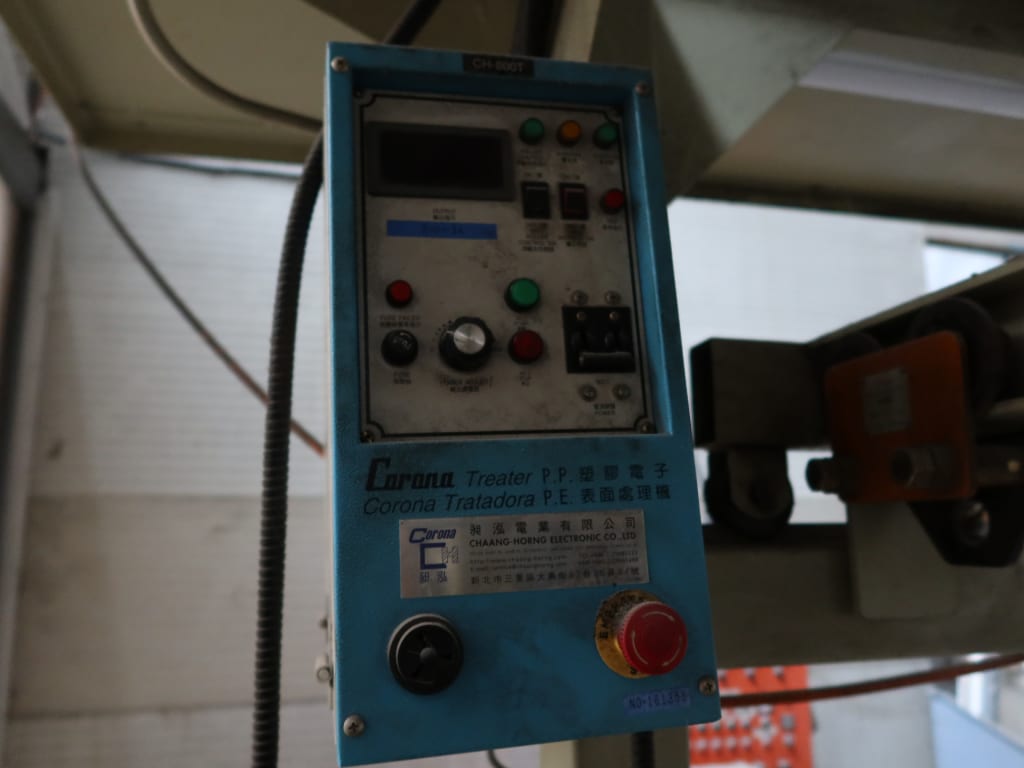

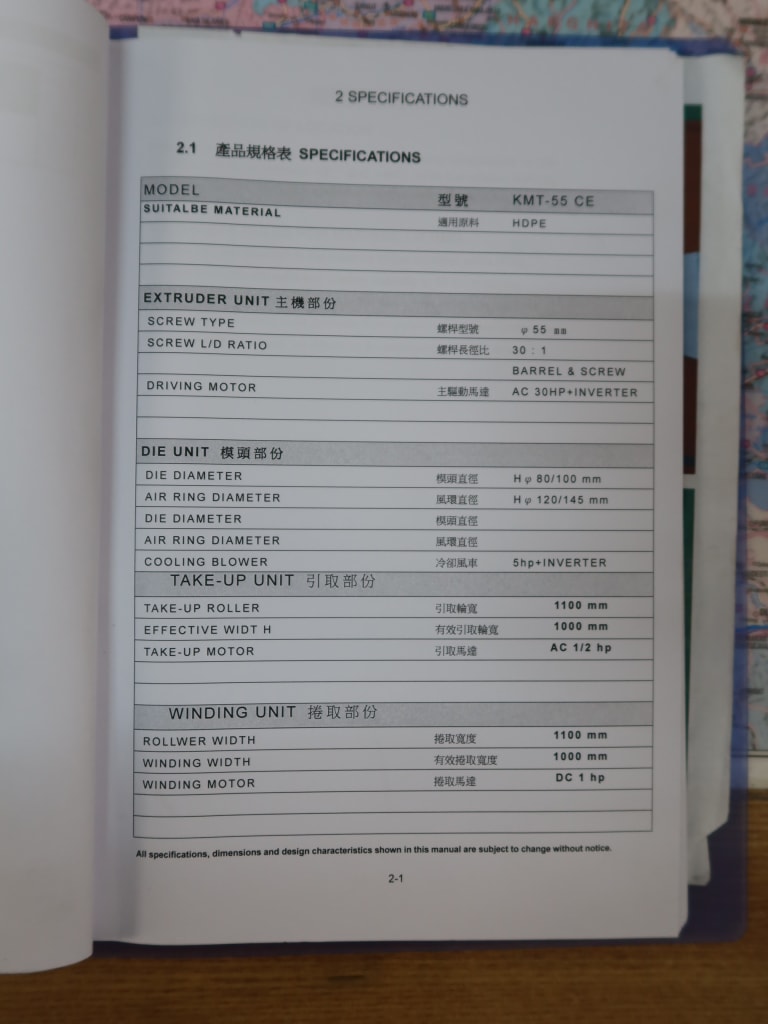

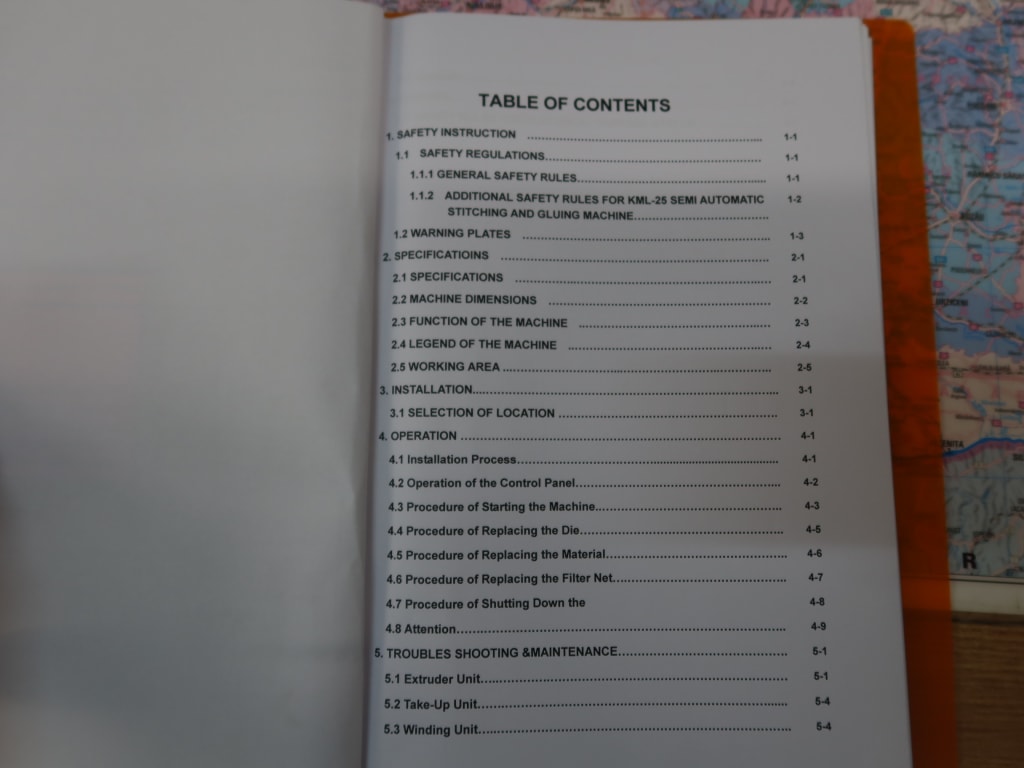

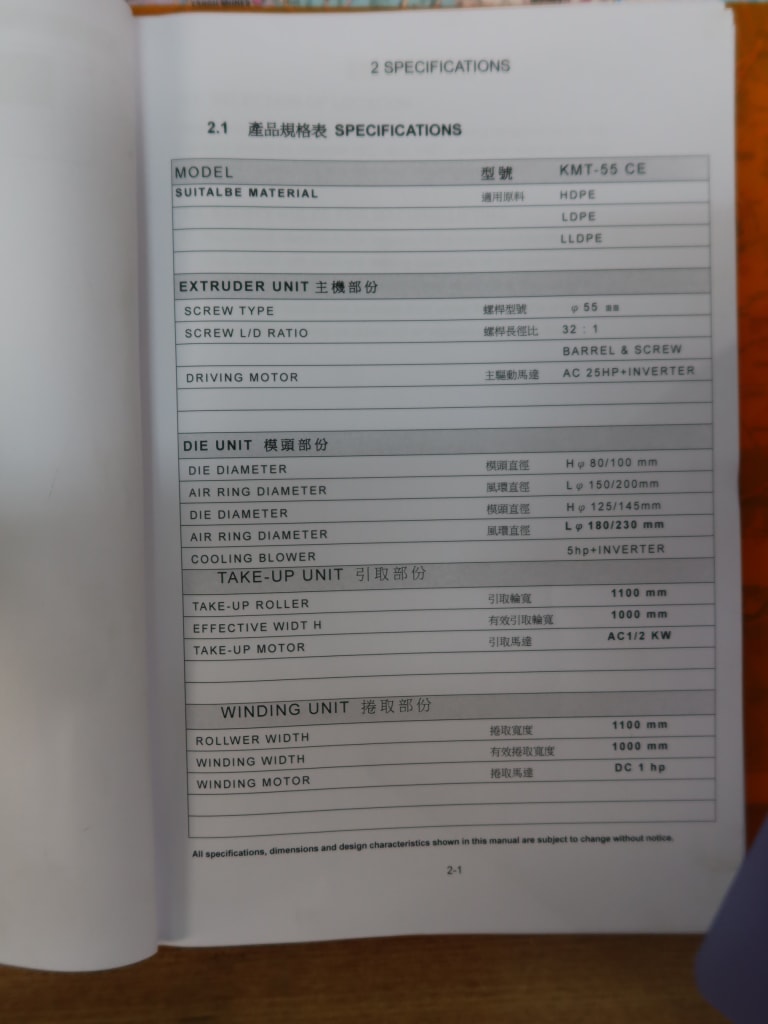

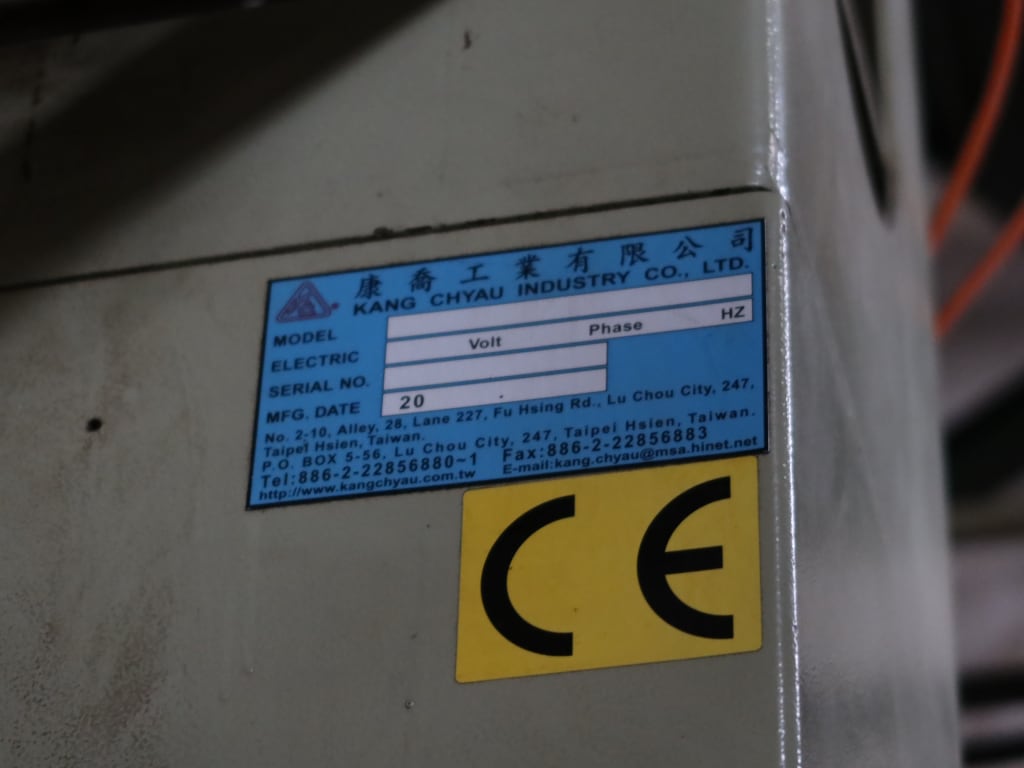

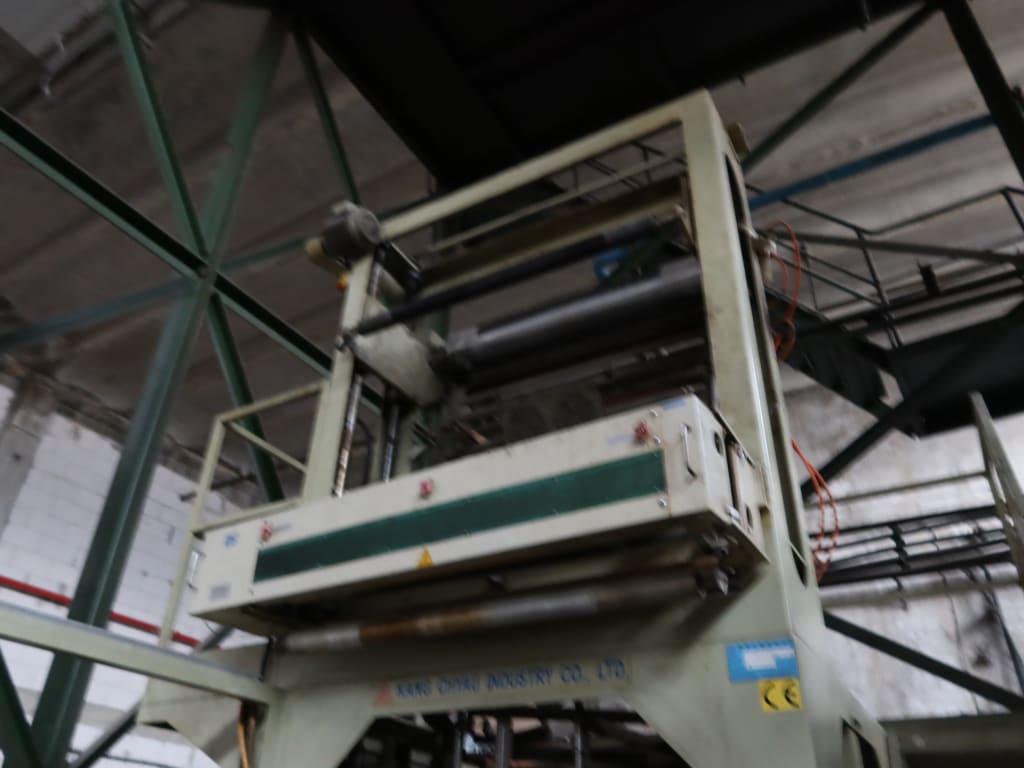

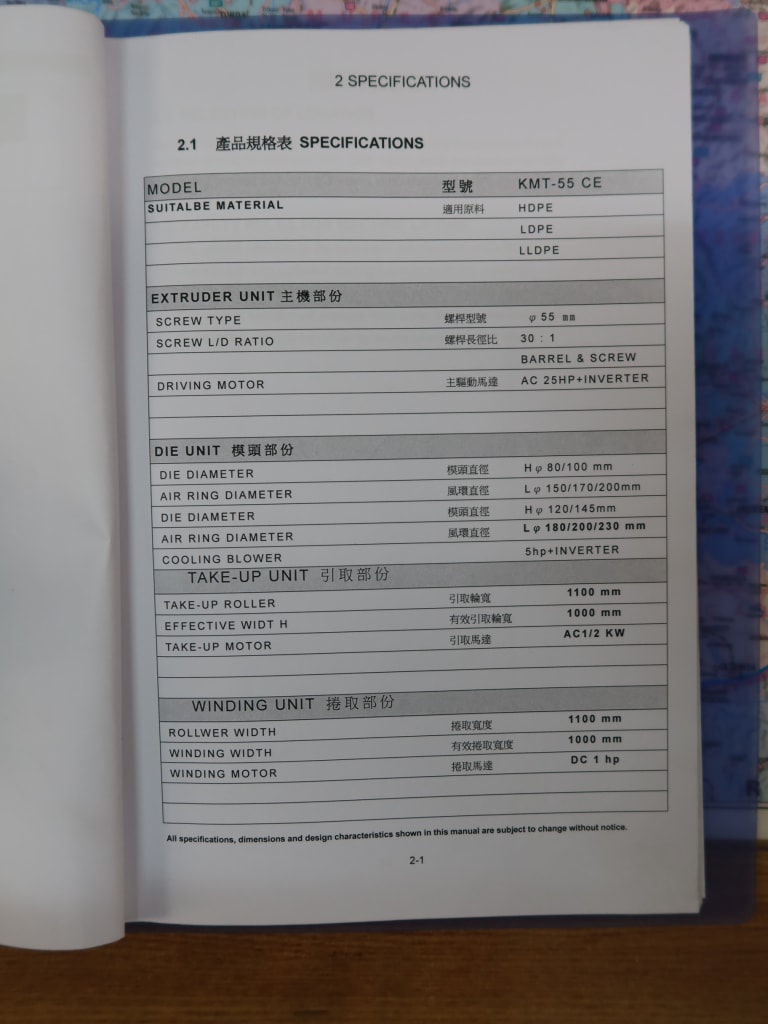

Kang Chyau KMT-55CE LDPE Blown Film Extrusion Line (2016)

Mono-layer Blown Film (LDPE) Production Line, Comprising Of The Following Main Components, Extruder: Screw Ø 55 mm, L/D 30:1. Blower Unit Ø 100 mm, Air Ring Diameter 120/145mm, Electrical Cabinet (Free-Standing Control Panel), Corona Treatment Unit (Integrated, Single-Side Surface Treatment Before Winding). Technical Data (Approx.): Film Material: LDPE, Film Thickness: 20 – 150 µm, Maximum Film Width: 1,600 mm (Unfolded) Or 1,100 mm (Folded). Output: ≈ 50 – 70 kg/h. Overall Dimensions: L7,500 × W2,500 × H4,500 mm. Metallic Frame: 1,300 × 1,300 × 4,500 mm. Power Supply: 380 V / 3 phase / 50 Hz. - LOT 3

![site]()

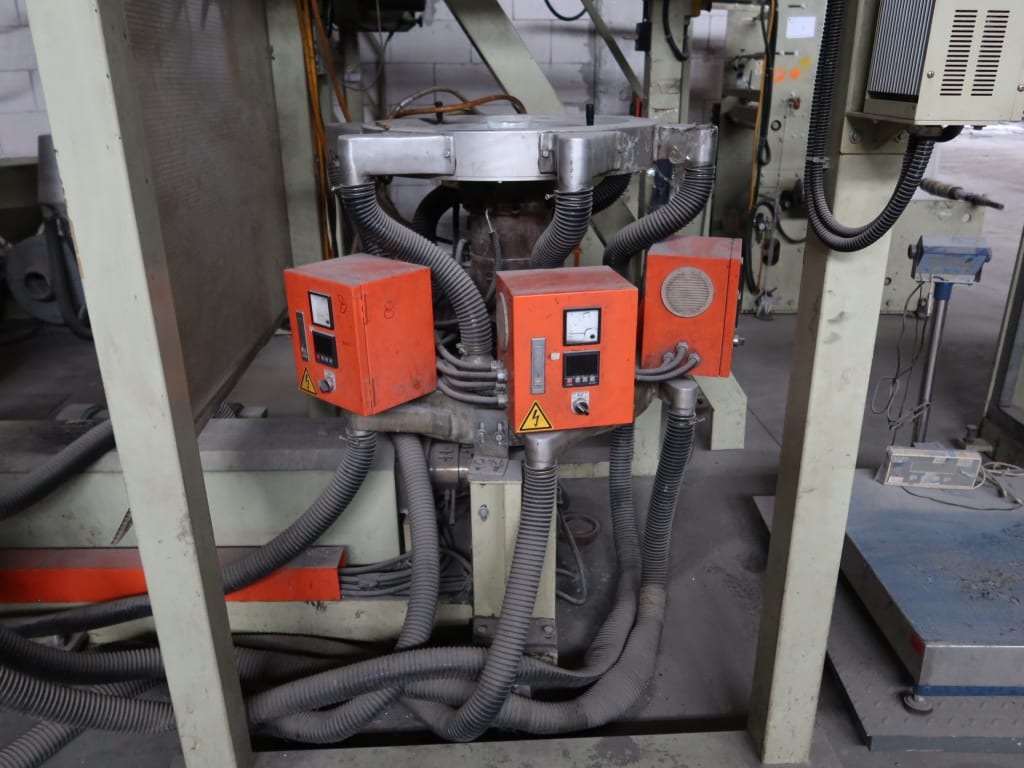

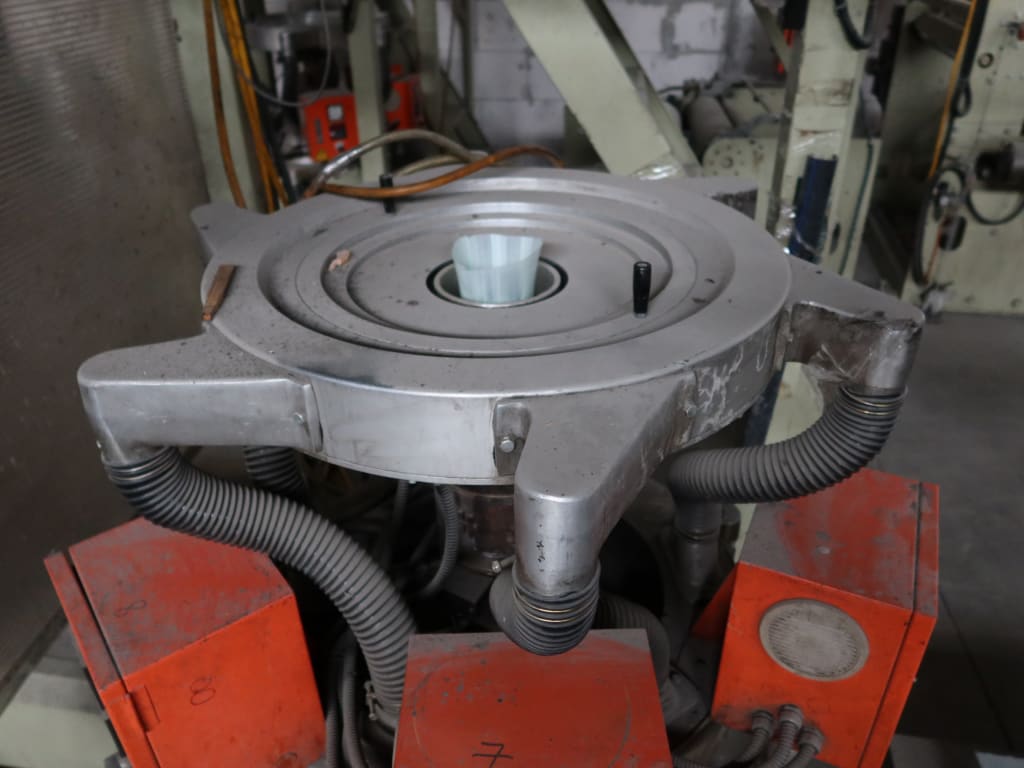

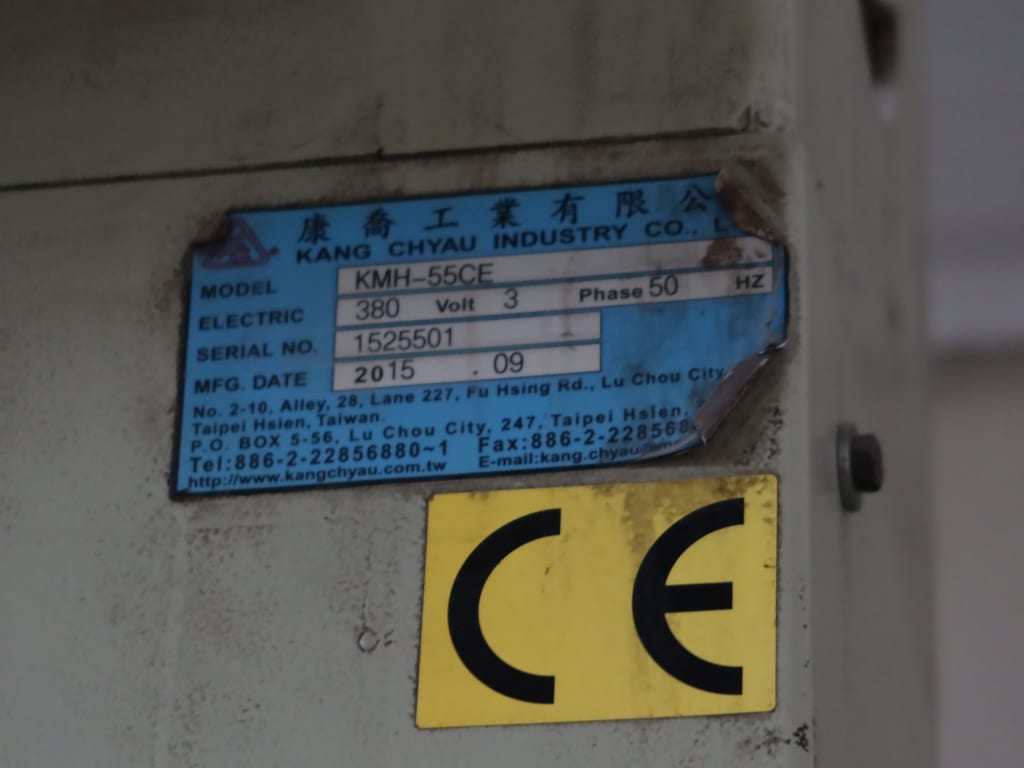

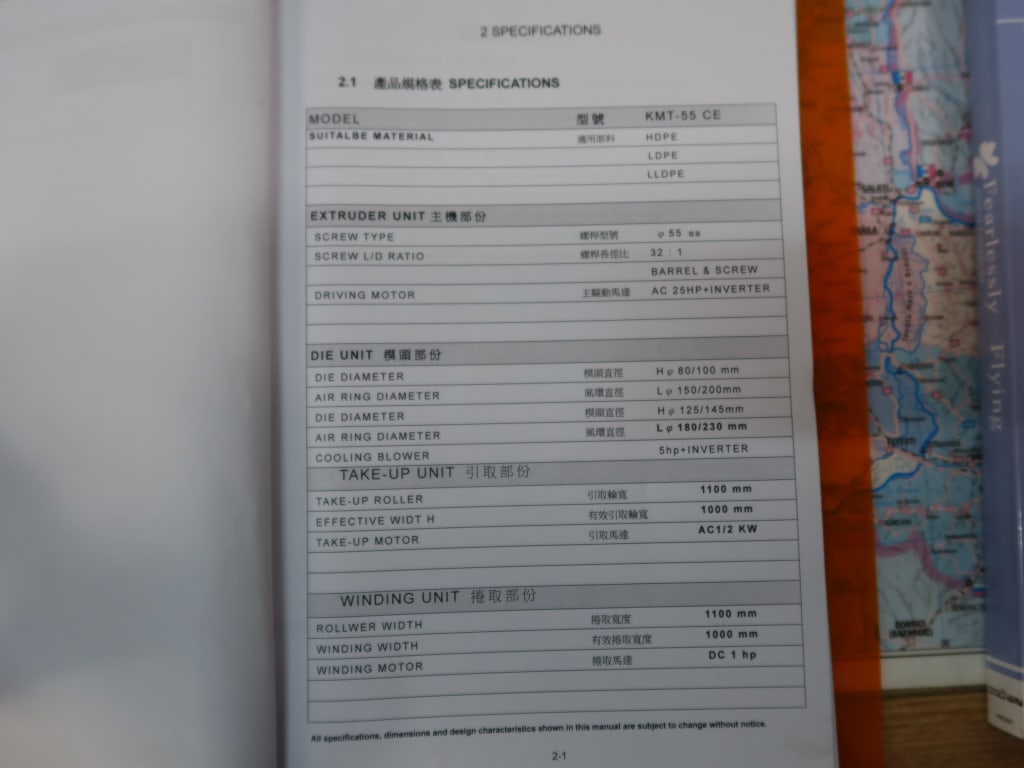

Kang Chyau KMH-55CE HDPE/MDPE Blown Film Extrusion Line (2015)

Blown Film (HDPE / MDPE) Production Line, Comprising Of The Following Main Components, Extruder: Screw Ø 55 mm, L/D Ratio 32:1, AC 25 HP Motor With Inverter. Die Head Ø 100 mm, Air Ring Ø 180 / 230 mm, Cooling Blower: 5 HP With Inverter. Downstream & Auxiliary Equipment: Haul-Off Unit: Effective Width 1 000 mm, Take-Up Roller Ø 1 100 mm, AC ½ HP Motor, Winding Unit: Double Winder, Roller Width 1 100 mm, DC 1 HP Motor, Electrical Control Panels: Independent Per Section, Corona Treatment Unit: Integrated, Single-Side Surface Treatment Before Winding. Technical Data (Approx.): Film Materials: HDPE / MDPE, Film Thickness: 14 – 75 µm, Maximum Film Width: 2 × 800 mm (Folded) (Total Lay-Flat ≈ 1 600 mm). Output: ≈ 50 – 70 kg/h. Overall Dimensions: L 7.500 × W 2.500 × H 4.500 mm. Metallic Frame: 1.300 × 1.300 × 4.500 mm. Power Supply: 380 V / 3 phase / 50 Hz. - LOT 4

![site]()

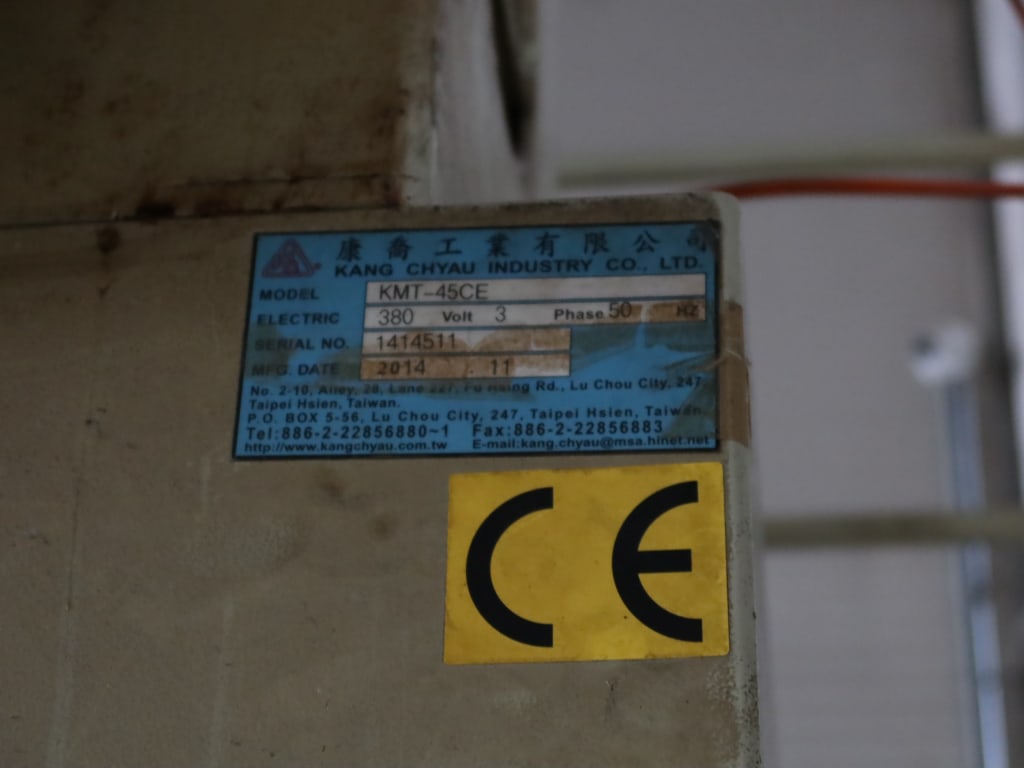

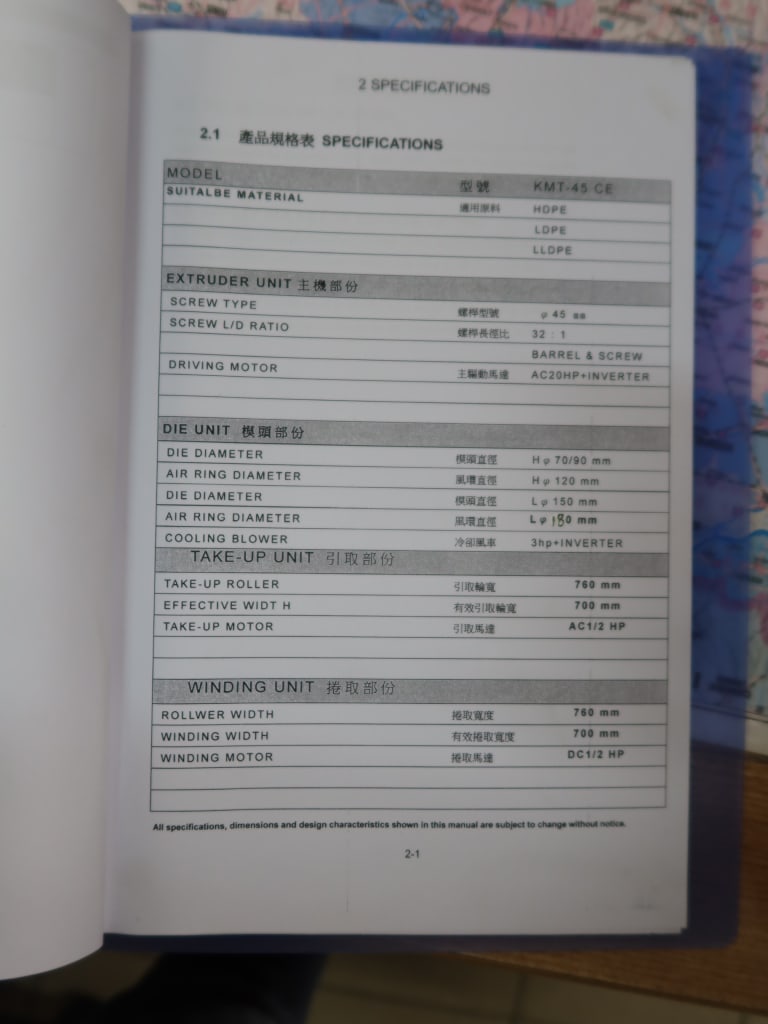

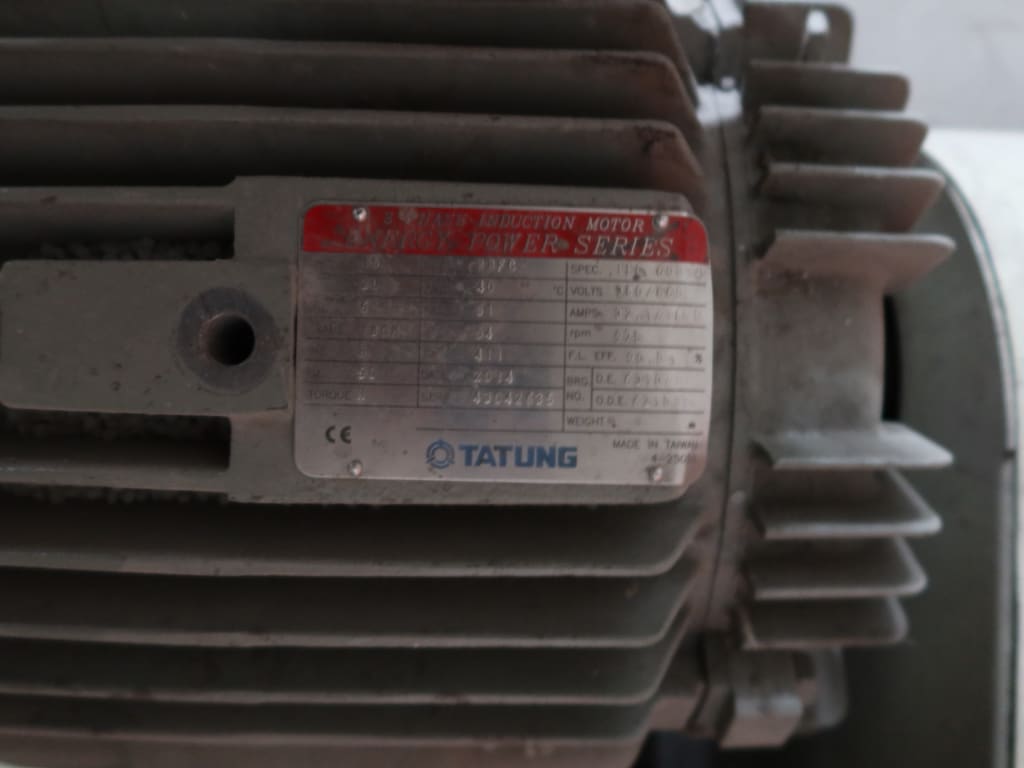

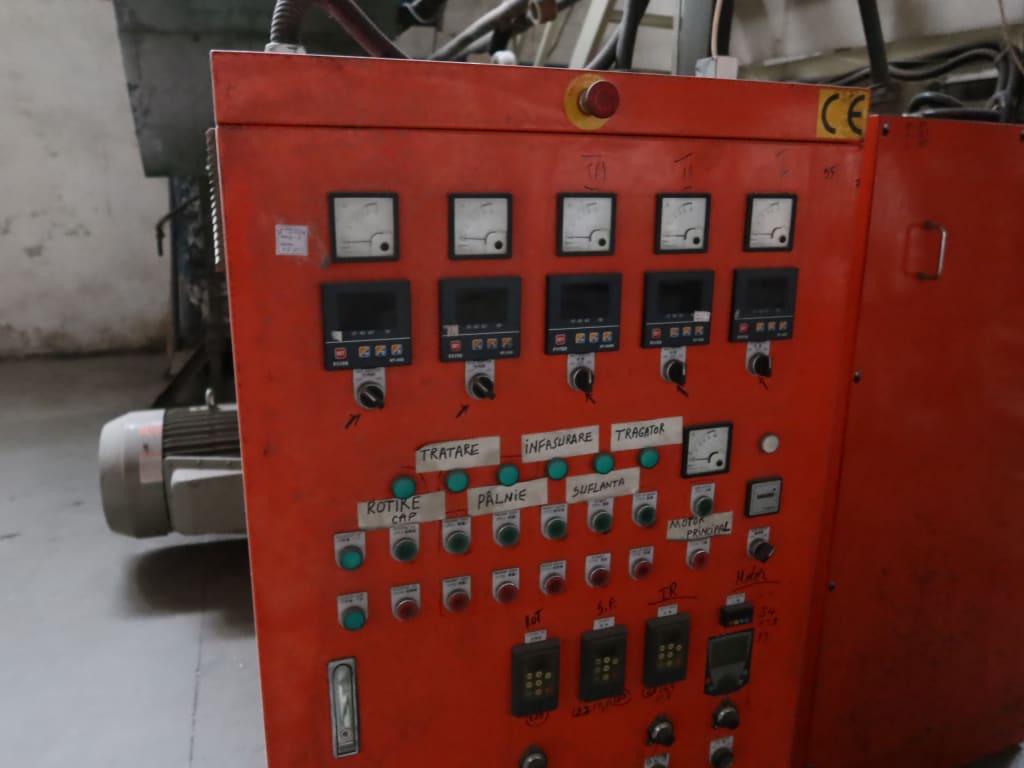

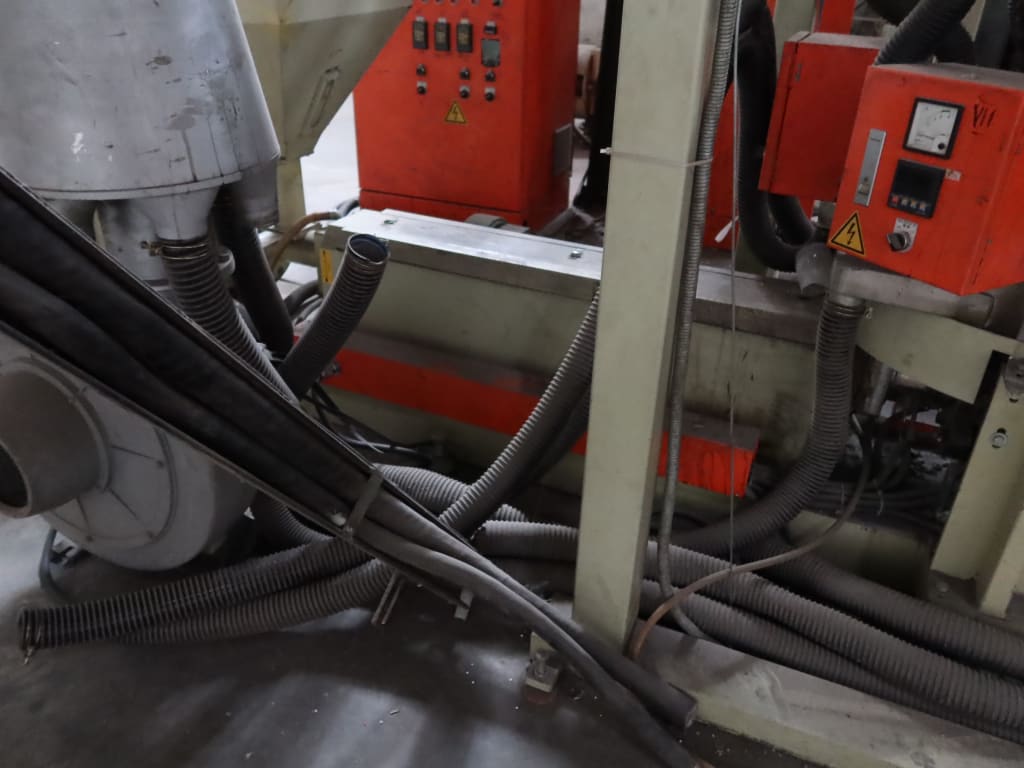

Kang Chyau KMT-45CE HDPE/LDPE Blown Film Extrusion Line (2014)

Blown Film (HDPE / LDPE / LLDPE) Production Line, Comprising Of The Following Main Components, Extruder: Screw Ø 45 mm, L/D 32:1, AC 20 HP Motor With Inverter. Die Head Ø 70 mm, Air Ring Ø 120 mm, Cooling Blower: 3 HP With Inverter. Downstream & Auxiliary Equipment: Haul-Off Section: Effective Width 700 mm, Roller Ø 760 mm, AC ½ HP Motor, Winder: Single Station, Roller Width 760 mm, DC ½ HP Motor, Corona Treatment Unit: Integrated, Single-Side Surface Treatment Before Winding, Electrical Cabinet: Free-Standing Panel. Technical Data (Approx.): Film Materials: HDPE / LDPE / LLDPE, Film Thickness: 20 – 100 µm, Max. Film Width: 700 mm (Folded) (Lay-Flat ≈ 1 400 mm). Output: ≈ 35 – 50 kg/h. Overall Dimensions: L 7.500 × W 2.500 × H 4.500 mm. Metallic Frame: 1.300 × 1.300 × 4.500 mm. Power Supply: 380 V / 3 phase / 50 Hz. - LOT 5

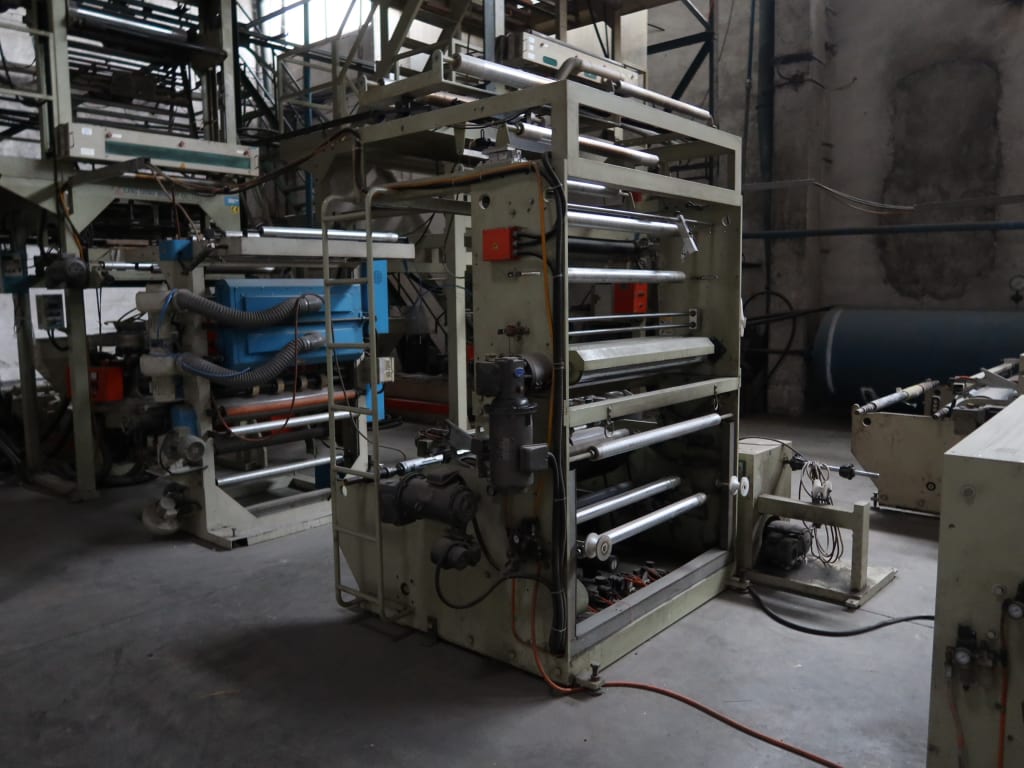

![site]()

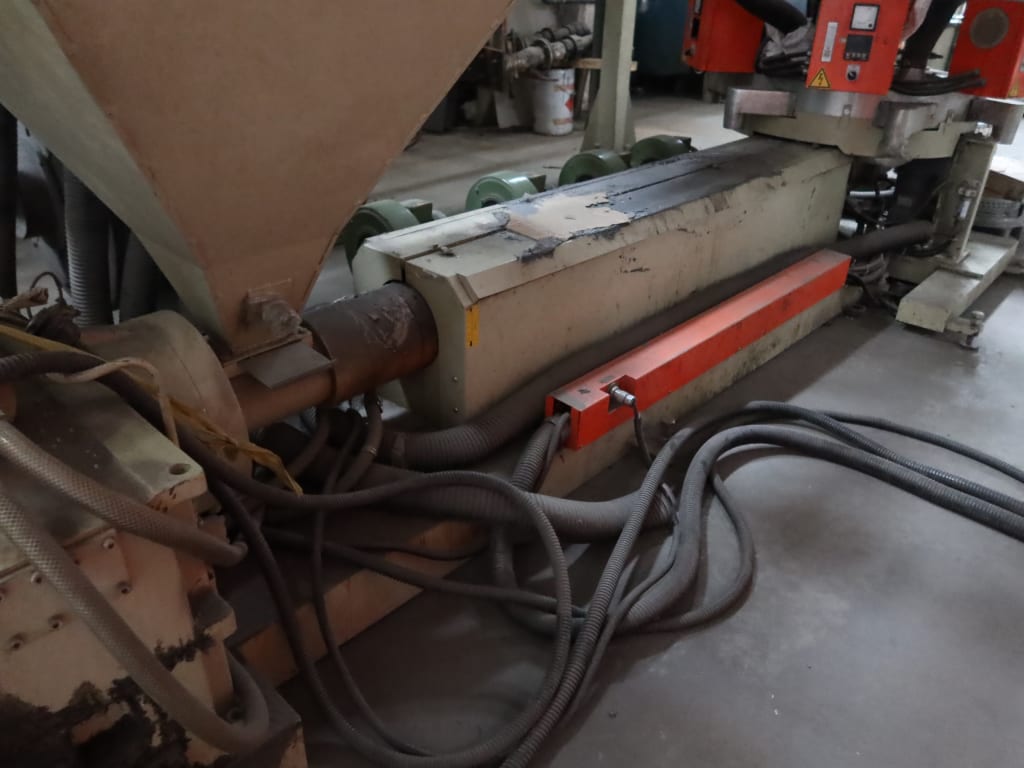

Kang Chyau KMT-55CE HDPE/LDPE Blown Film Extrusion Line (2004)

Blown Film (HDPE / LDPE / LLDPE) Production Line, Comprising Of The Following Main Components, Extruder: Screw Ø 55 mm, L/D 30:1, AC 25 HP Motor With Inverter. Die Head Ø 150 mm, Air Ring Ø 150 / 200 / 230 mm, Cooling Blower: 5 HP With Inverter. Downstream & Auxiliary Equipment: Haul-Off Unit: Roller Width 1.100 mm, Effective Width 1.000 mm, AC ½ HP Motor, Winding Unit: Double Winder, Roller Width 2 × 2.000 mm, DC 1 HP Motor, Corona Treatment Unit: Inline Single-Side Surface Treatment Mounted Before Winder, Electrical Cabinet: Free-Standing Control Panel. Technical Data (Approx.): Film Materials: HDPE / LDPE / LLDPE, Film Thickness: 20 – 150 µm, Maximum Film Width: 1.000 mm (Folded) (≈ 2.000 mm Unfolded). Output: ≈ 50 – 70 kg/h. Overall Dimensions: L 10.000 × W 3.500 × H 5.000 mm. Metallic Frame Dimensions: L 1.100 × W 2.000 × H 5.000 mm. Power Supply: 380 V / 3 phase / 50 Hz. - LOT 6

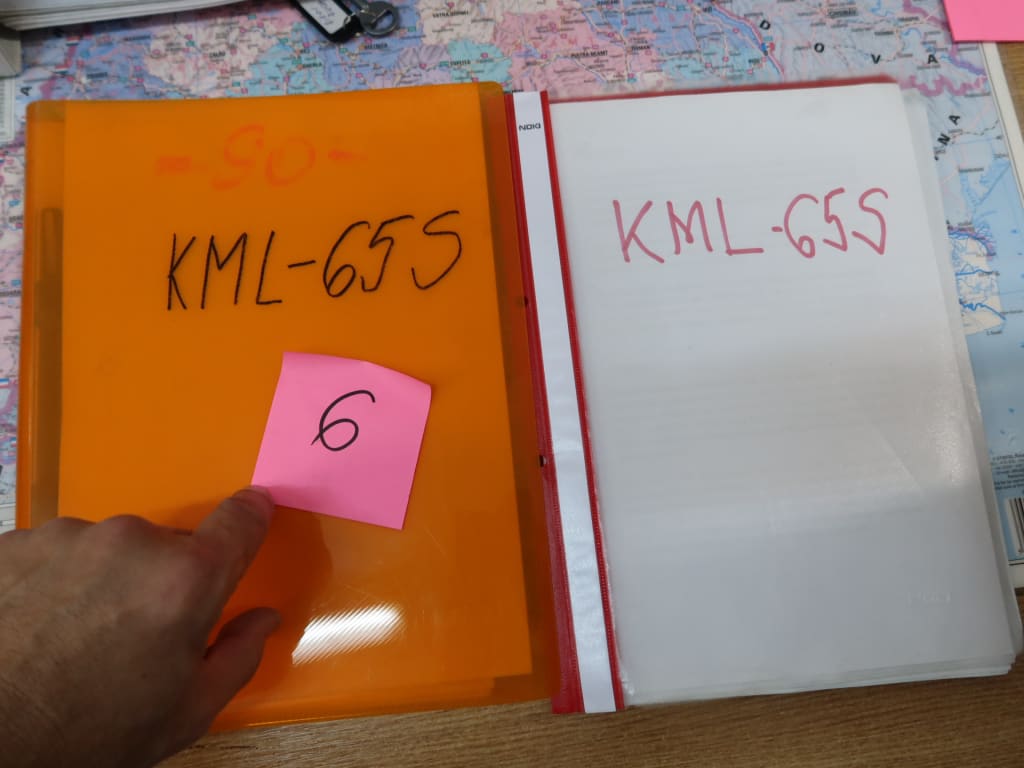

![site]()

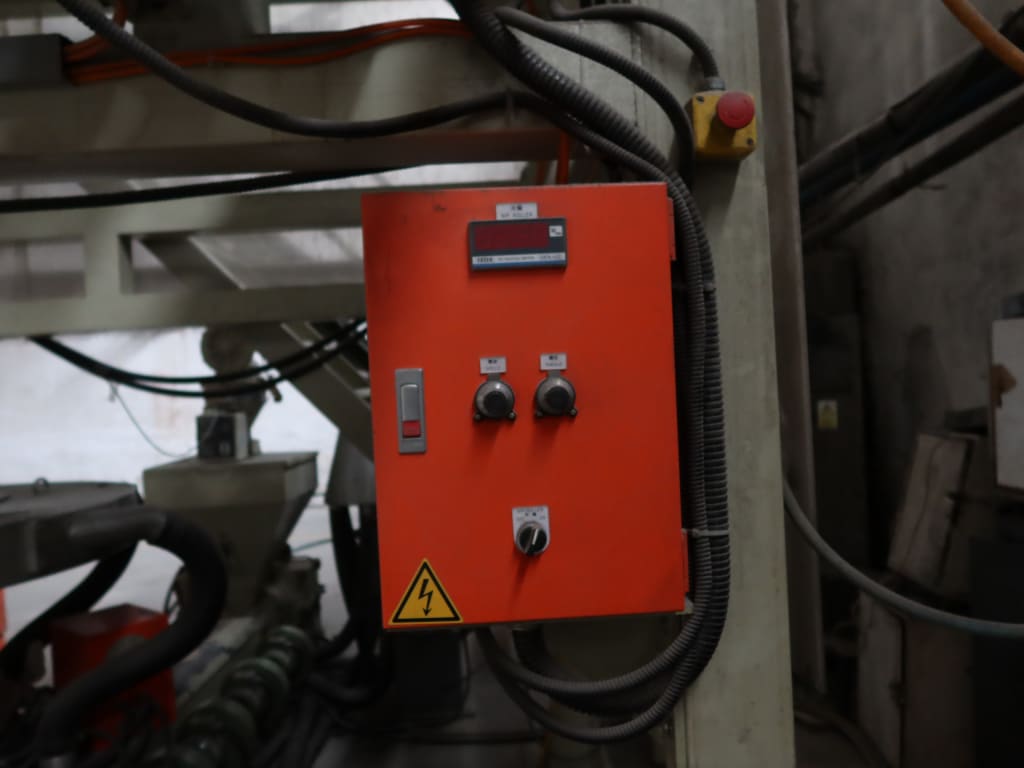

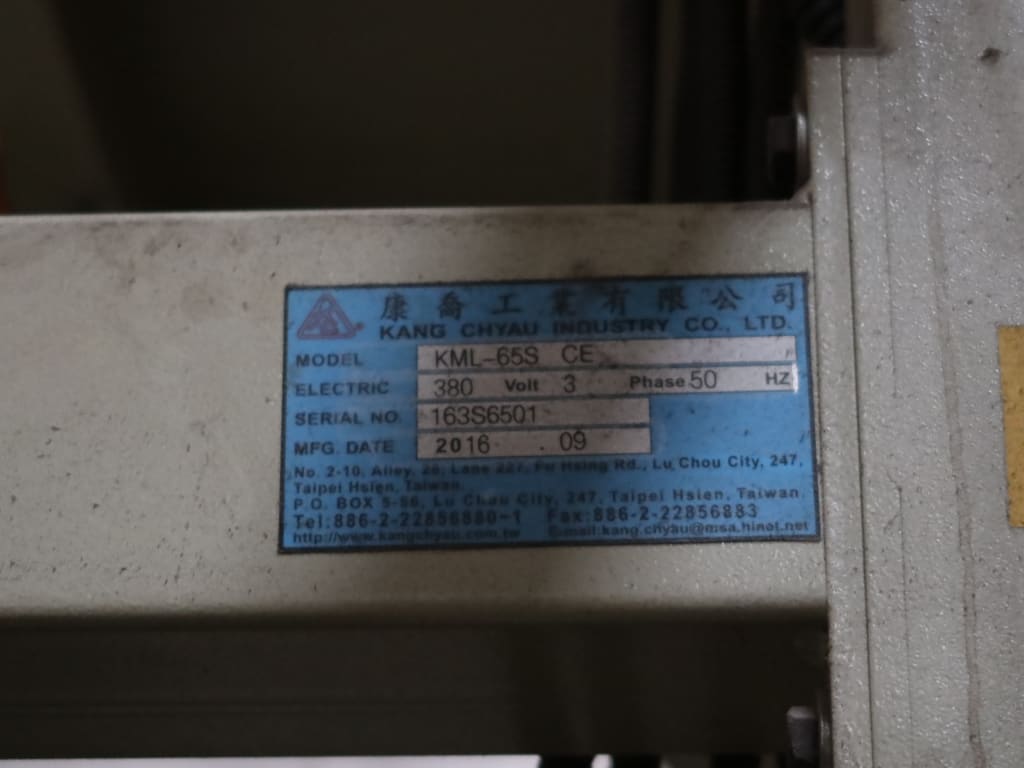

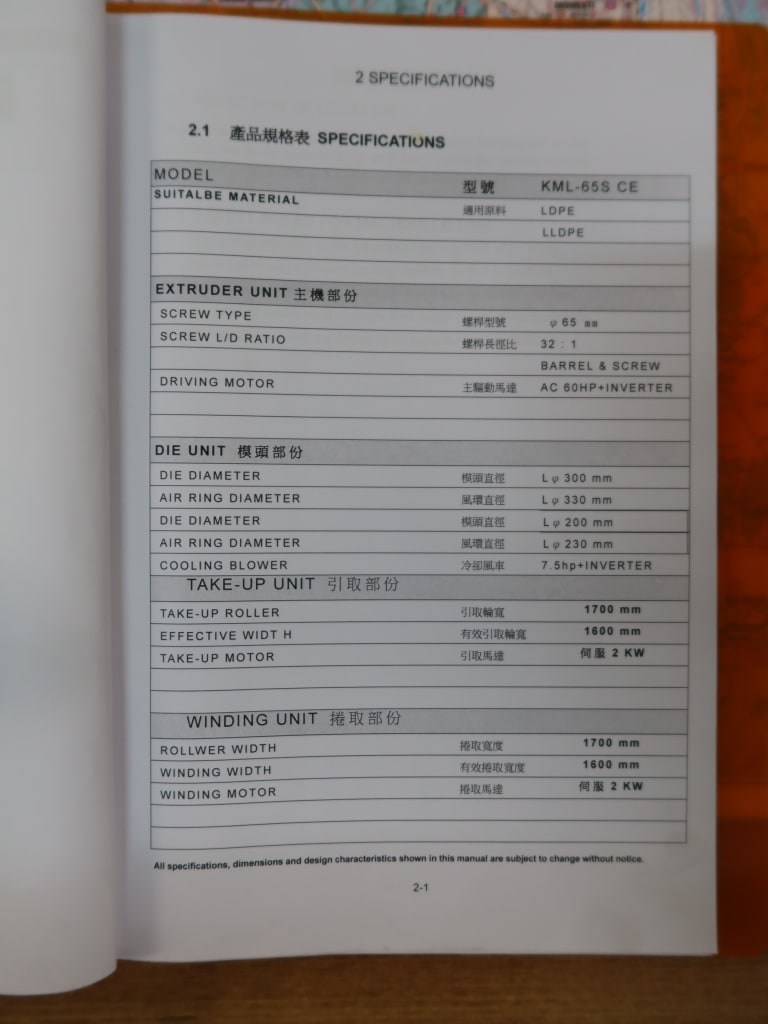

Kang Chyau KML-65S CE LDPE/LLDPE Blown Film Extrusion Line (2016)

Blown Film (LDPE / LLDPE) Production Line, Comprising Of The Following Main Components, Extruder: Screw Ø 65 mm, L/D 32:1, AC 60 HP Motor With Inverter. Die Head Ø 200 mm, Air Ring Ø 230 mm, Cooling Blower: 7.5 HP With Inverter, Dosing Unit: Gravimetric Feeder For Polymer And Masterbatch. Downstream & Auxiliary Equipment: Haul-Off Unit: Roller Width 1.700 mm, Effective Width 1.600 mm, Take-Up Motor 2 kW, Winding Unit: Roller Width 1.700 mm, Winding Width 1.600 mm, Winding Motor 2 kW, Corona Treatment Unit: Inline Single-Side Treatment Before Winding, Electrical Control Cabinet: Free-Standing, Integrated Inverter Drives. Technical Data (Approx.): Film Materials: LDPE / LLDPE, Film Thickness: 20 – 150 µm, Maximum Film Width: 1.600 mm (Folded) (≈ 3.200 mm Unfolded). Output: Up To 120 kg/h (Depending On Polymer And Film Gauge). Overall Dimensions: L 13.000 × W 4.000 × H 9.500 mm. Metallic Frame Dimensions: L 3.500 × W 2.000 × H 7.500 mm. Power Supply: 380 V / 3 phase / 60 Hz. - LOT 7

![site]()

3 MEP 60/1200 Film Extrusion Lines

Set of three mono-layer polyethylene blown-film extrusion lines, Comprising Of The Following Main Components, Extruder: Estimated Screw Ø 60 mm. Die Head: Approx. Ø 180 mm (Single-Layer). Air Ring & Tower: Standard Single-Blower Design. Downstream & Auxiliary Equipment: Haul-Off & Winder: Mechanical Drive With Analog Controls, Control System: Original Cabinet With Relay-Based Panels. Technical Data (Indicative, Unverified): Film Material: LDPE / HDPE, Film Thickness: 25 – 150 µm (Typical Range), Film Width: Up To ≈ 1.200 mm (Folded). Output: ≈ 40 – 60 kg/h Per Line. Overall Dimensions: L 17.000 × W 10.000 × H 7.500 mm. Power Supply: 380 V / 3 ph / 50 Hz - LOT 8

![site]()

2 C.M.F. Carint MS 7204 Colour Flexographic Printing Lines

2 Colour Printing Line (LDPE / HDPE / PP), Comprising Of The Following Main Components: Printing Units: 2 Colours, Stack-Type, Mechanical Drive. Downstream & Auxiliary Equipment: Unwinder And Rewinder: Independent Units For Two Film Webs, Drying System: Hot-Air System With Upper Ventilation And Exhaust, Inking System: Individual Ink Pumps And Doctor Blade Assemblies, Control Cabinet: Analog/Relay-Based Control Panel. Technical Data (Approx.): Film Materials: LDPE / HDPE / PP, Colours: 2, Printing Width: Up To ≈ 1.100 mm, Printing Repeat: ≈ 300 – 800 mm, Max. Speed: ≈ 80 m/min (Est.). Overall Dimensions: L 5.500 × W 2.500 × H 3.500 mm. Power Supply: 380 V / 3 ph / 50 Hz. - LOT 9

![site]()

C.M.F. Carint GSA 1202 Colour Flexographic Printing Line (1980)

1 Colour Printing Line, Comprising Of The Following Main Components, One Printing Deck: 1 Colour. Downstream & Auxiliary Equipment: Unwinder And Rewinder: With Mechanical Drive, Ink And Drying Units, Ventilation And Exhaust Ducting. Technical Data (Approx.): Overall Dimensions: L 4.600 × W 2.500 × H 3.500 mm. - LOT 10

![site]()

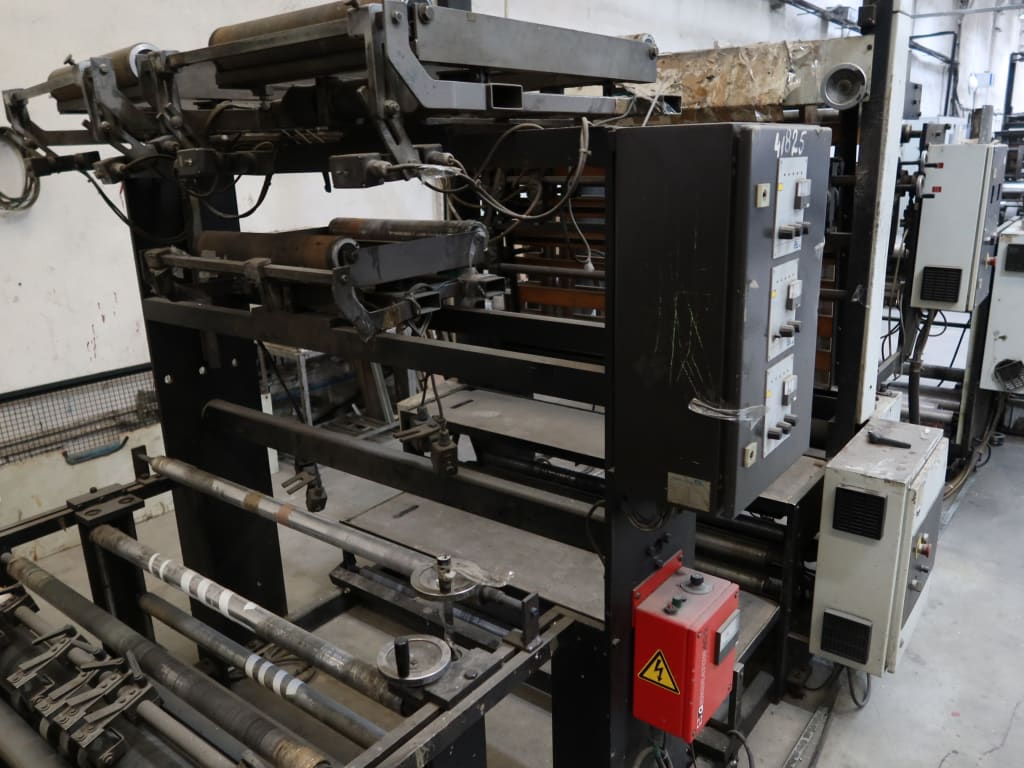

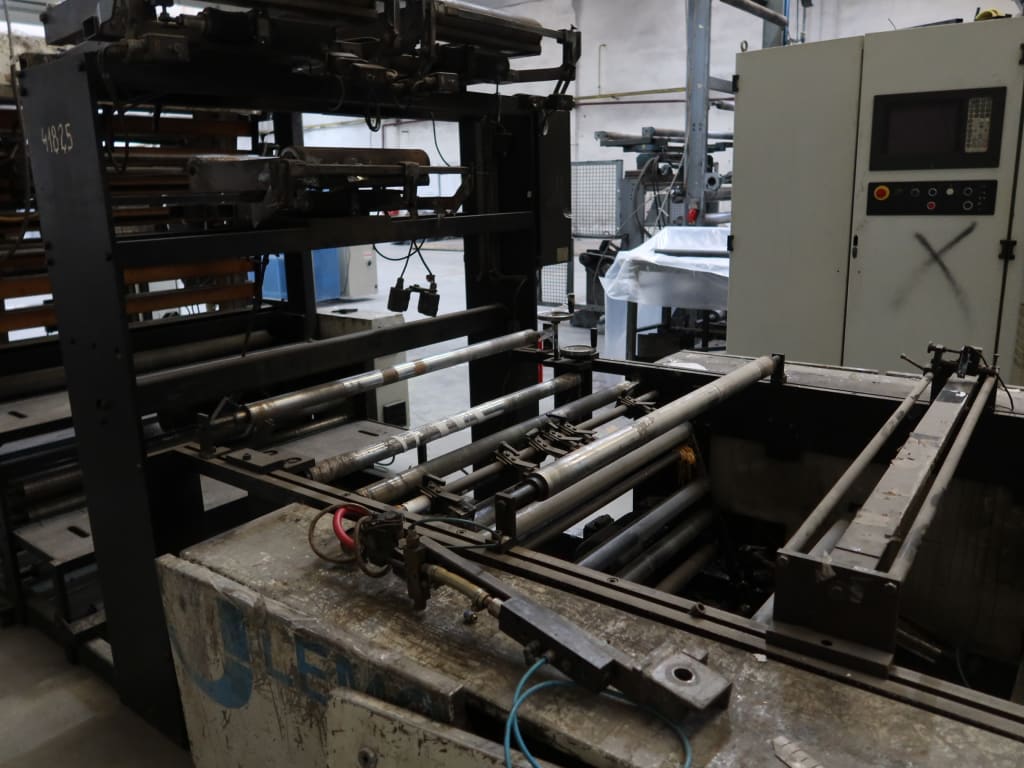

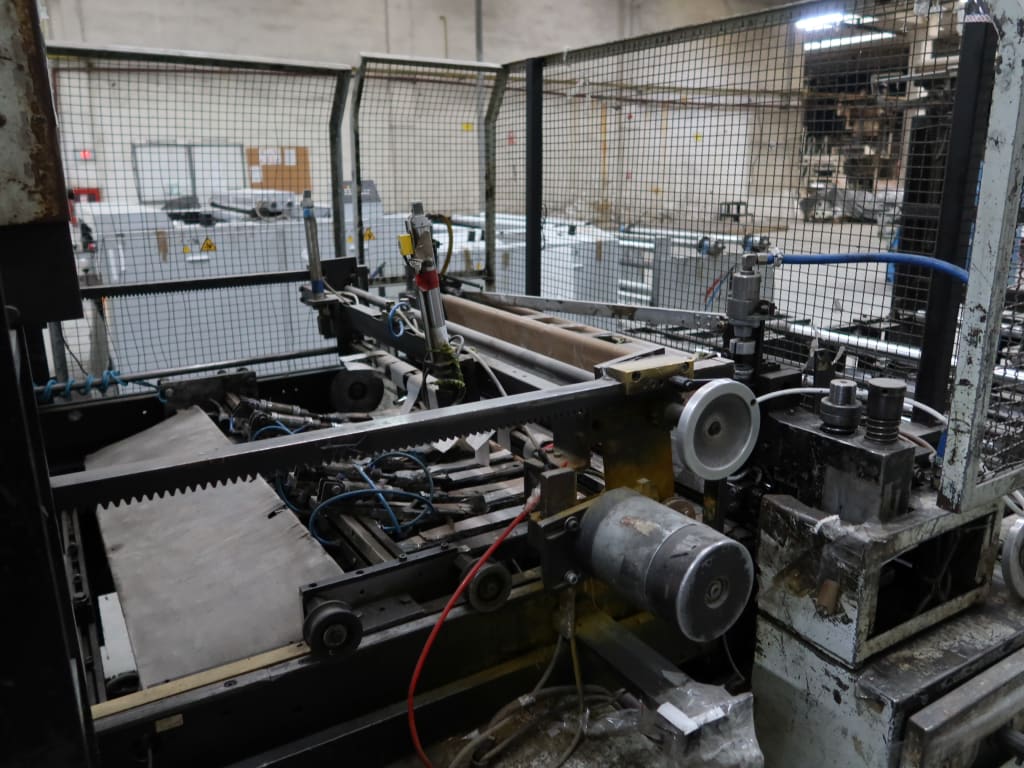

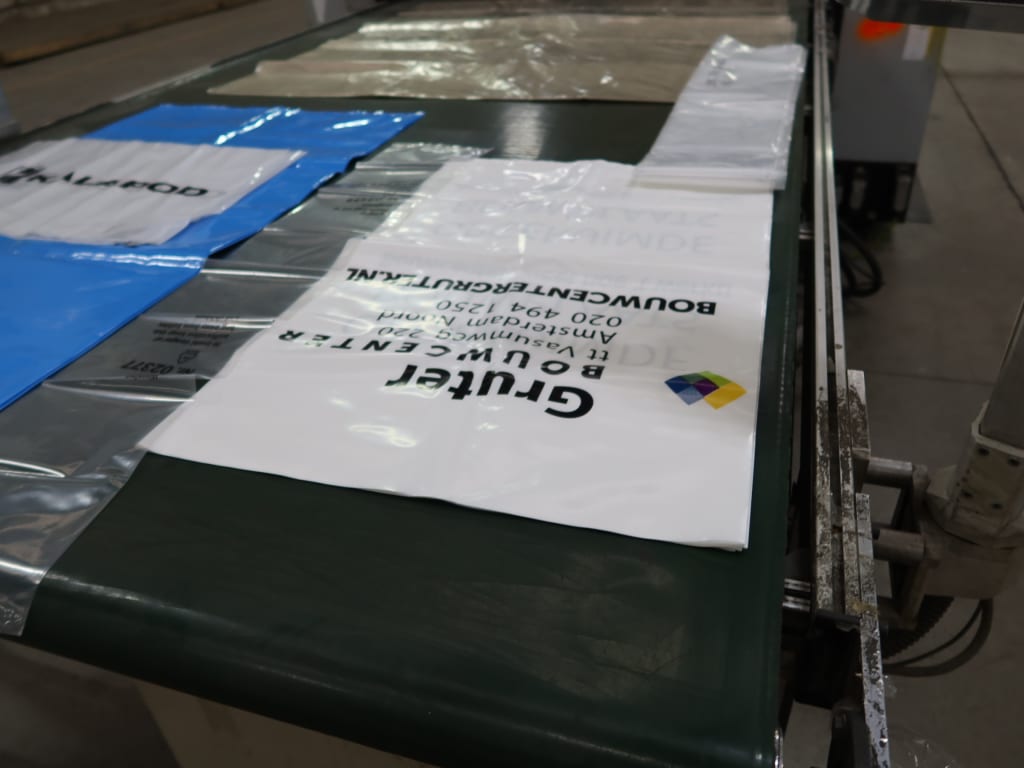

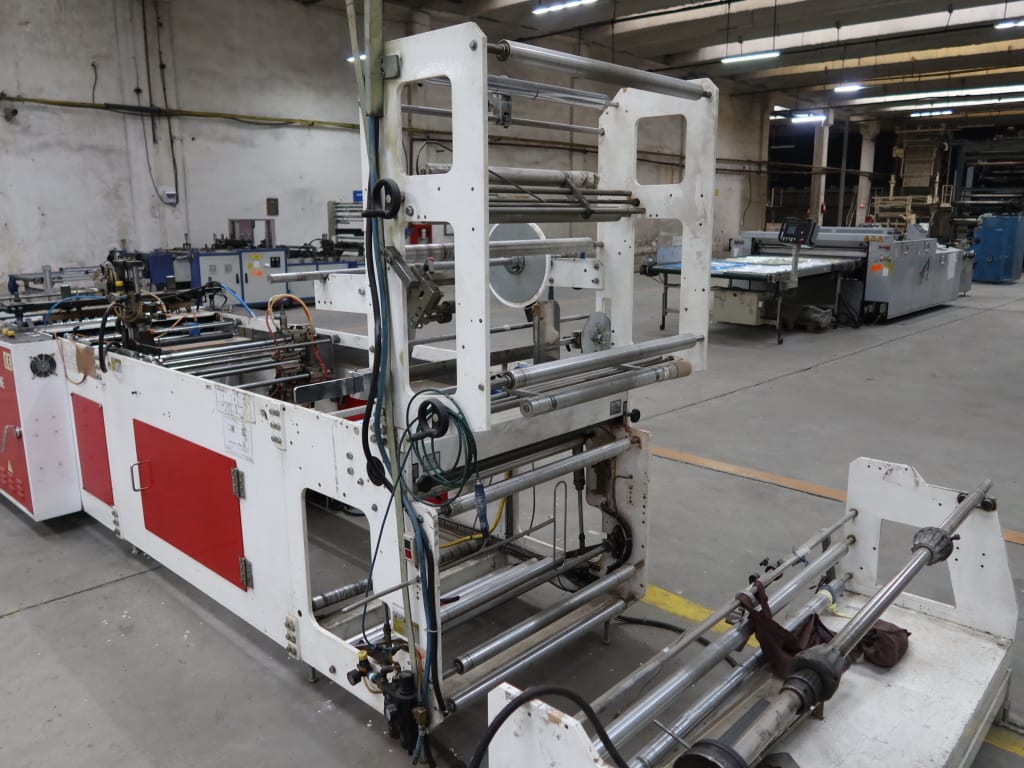

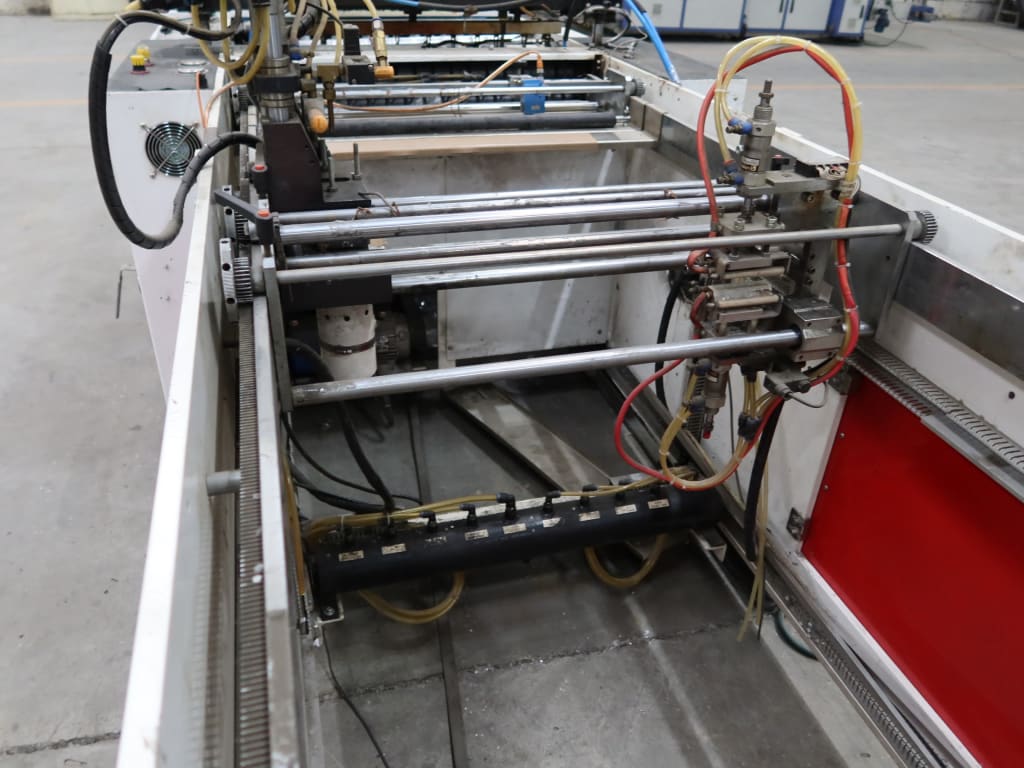

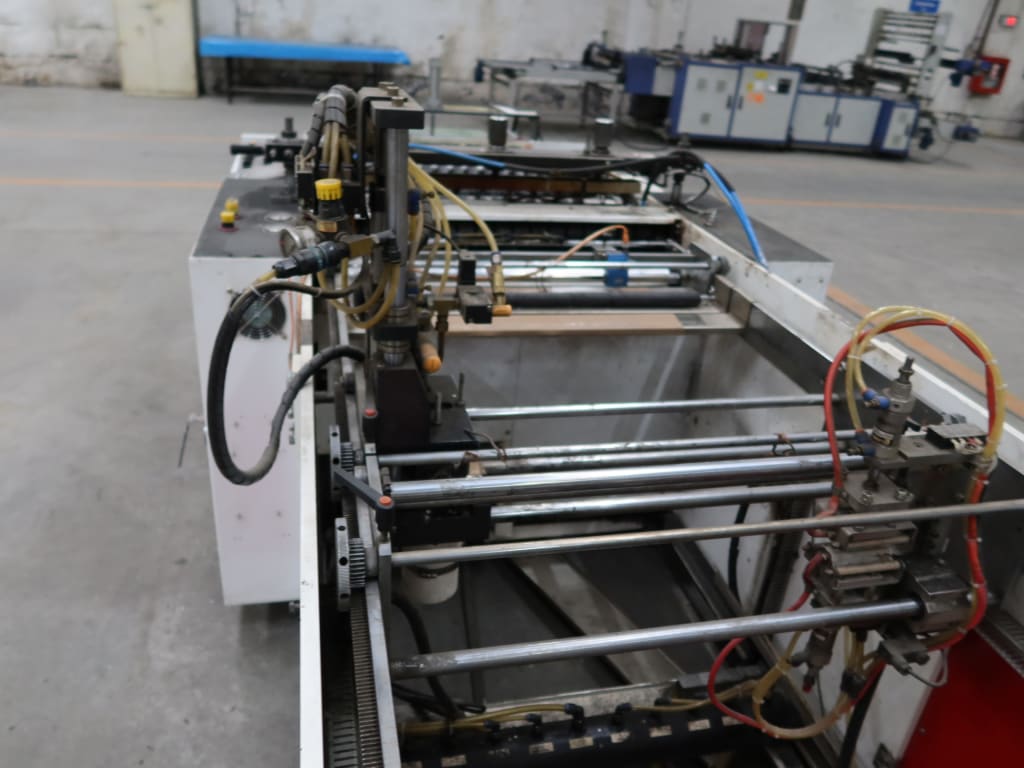

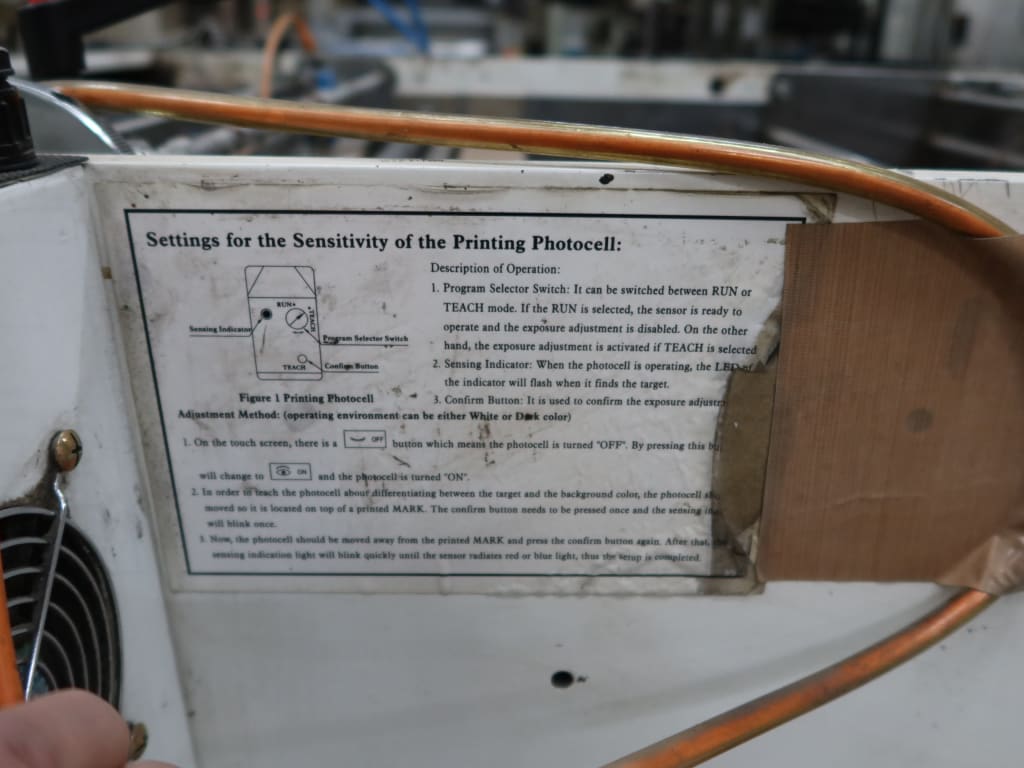

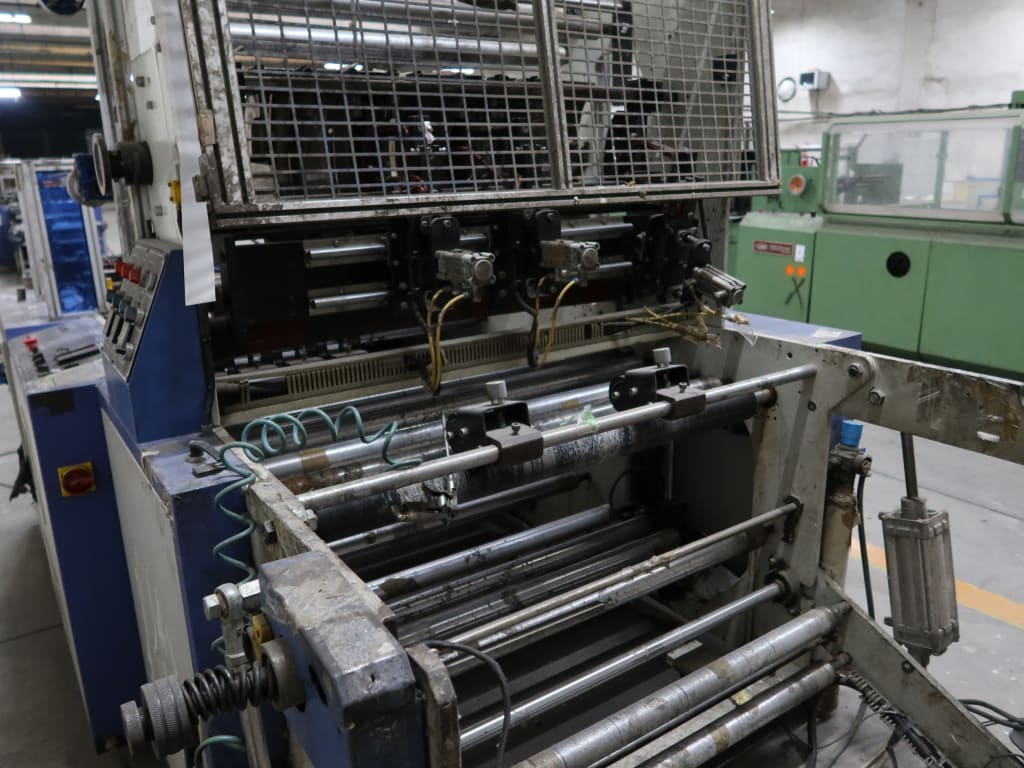

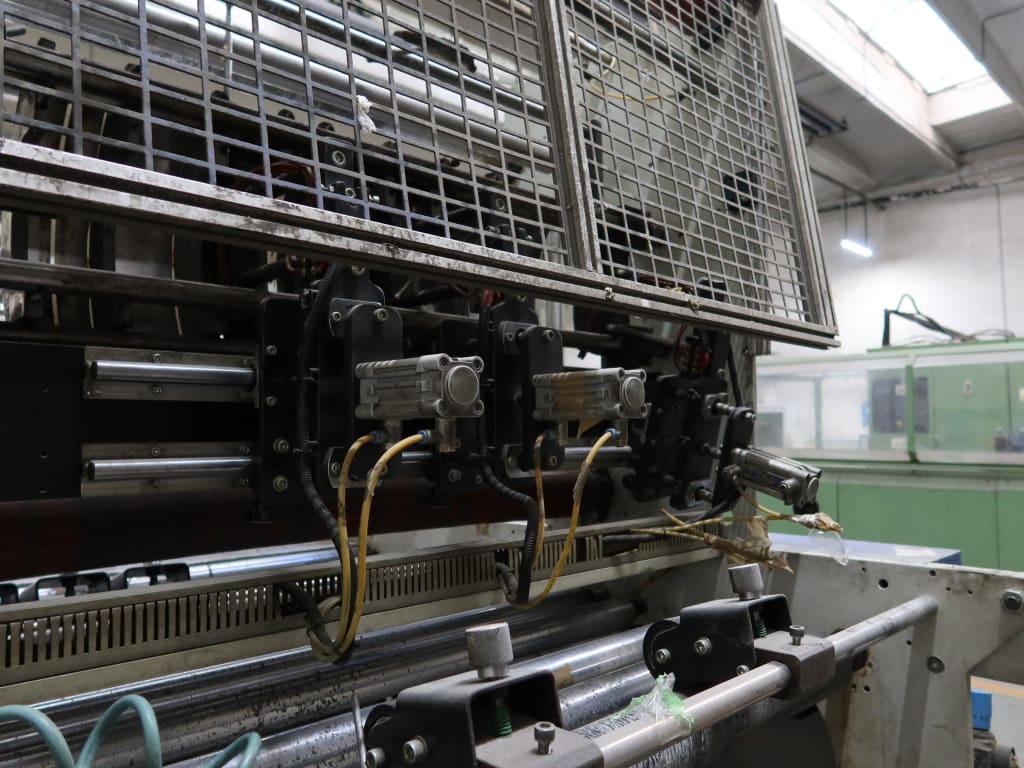

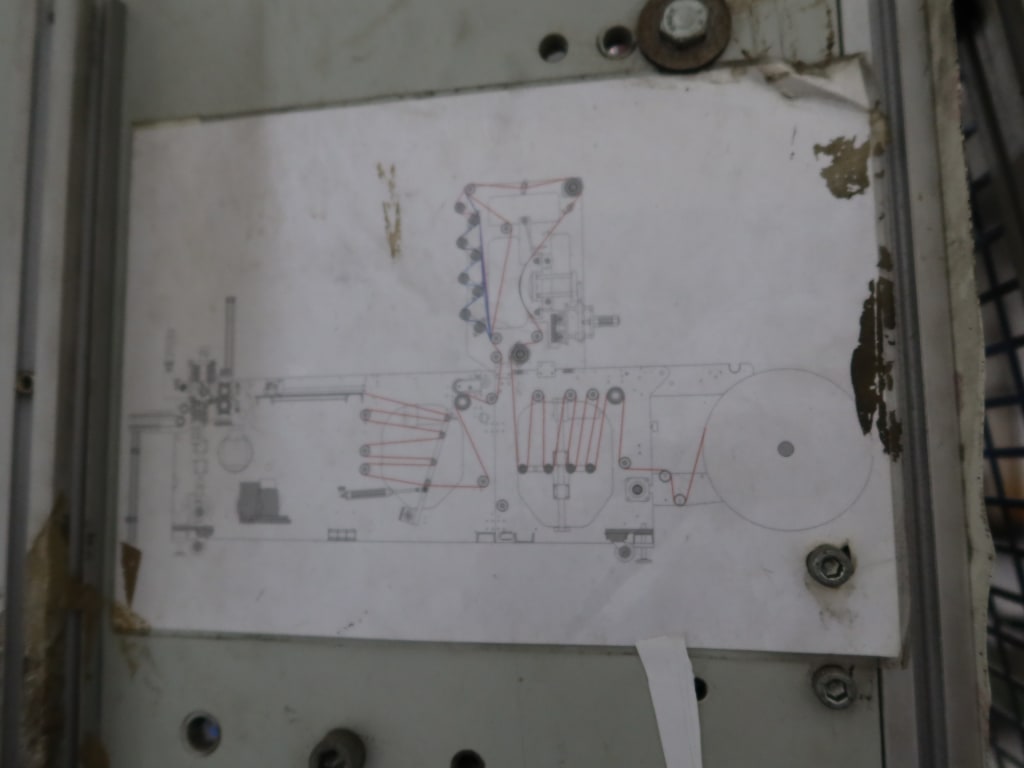

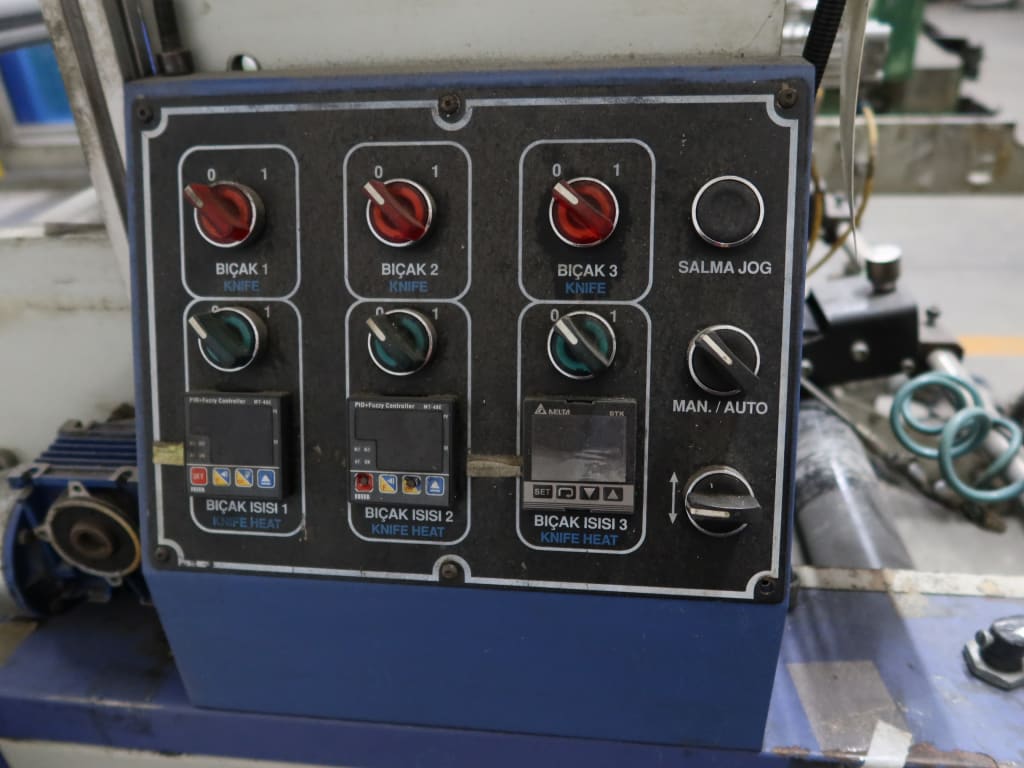

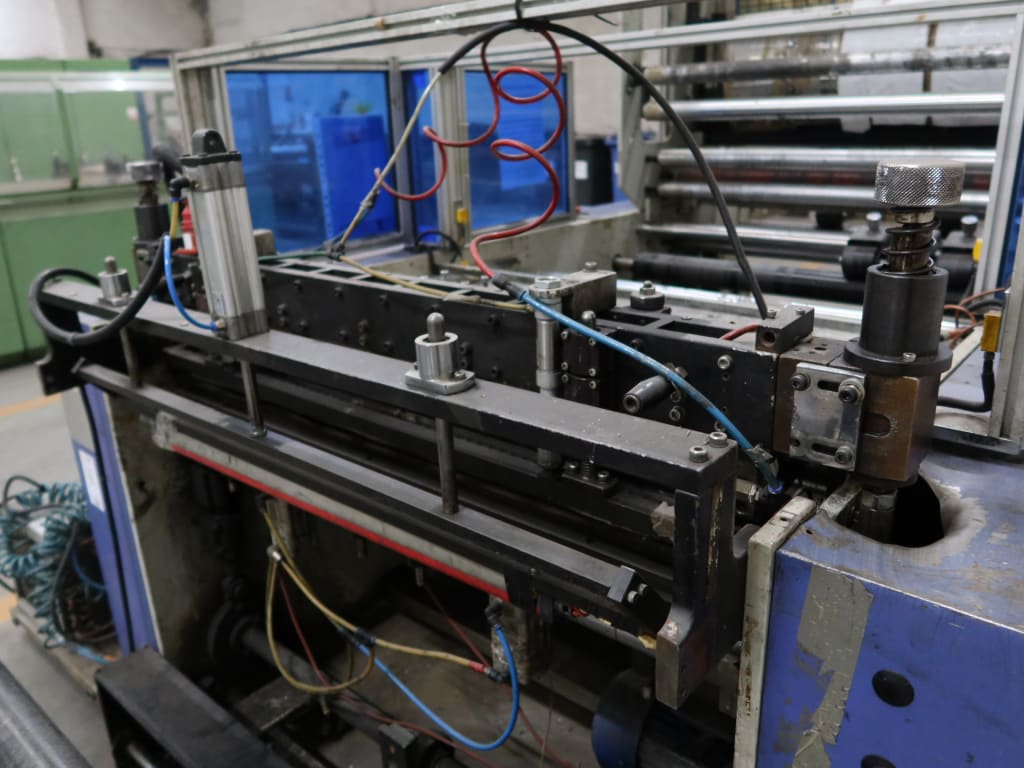

LEMO-INTERMAT 2 T-Shirt Bag Making Line

T-Shirt Bag Making Line, Comprising Of The Following Main Components, Unwinder: For Tubular Or Folded Film. Longitudinal Cutting Section: With 2 Knives (Splitting Into 3 Lanes). Longitudinal Welding Unit. Folding Station: With 4 Folds (Left/Right Max 100 mm), Lane Guiding System: EL, Bottom Sealing And Cutting Station: Thermal Weld, Transverse, Discharge Conveyor, Electrical Cabinet: Approx. 2.500 × 600 × 2.200 mm. Technical Data (Approx.): Input Film Width: Max. 900 mm, Max. Film Roll Diameter: 800 mm, Typical Product: T-Shirt–Type Plastic Bags With Bottom Seal And Side Gussets, Bags Length: 300 – 700 mm, Bags Width: 150 – 300 mm, Working Configuration: Currently Operational On 2 Lanes (One Lane Defective). Overall Dimensions: L 11.000 × W 2.500 × H 2.500 mm. - LOT 11

![site]()

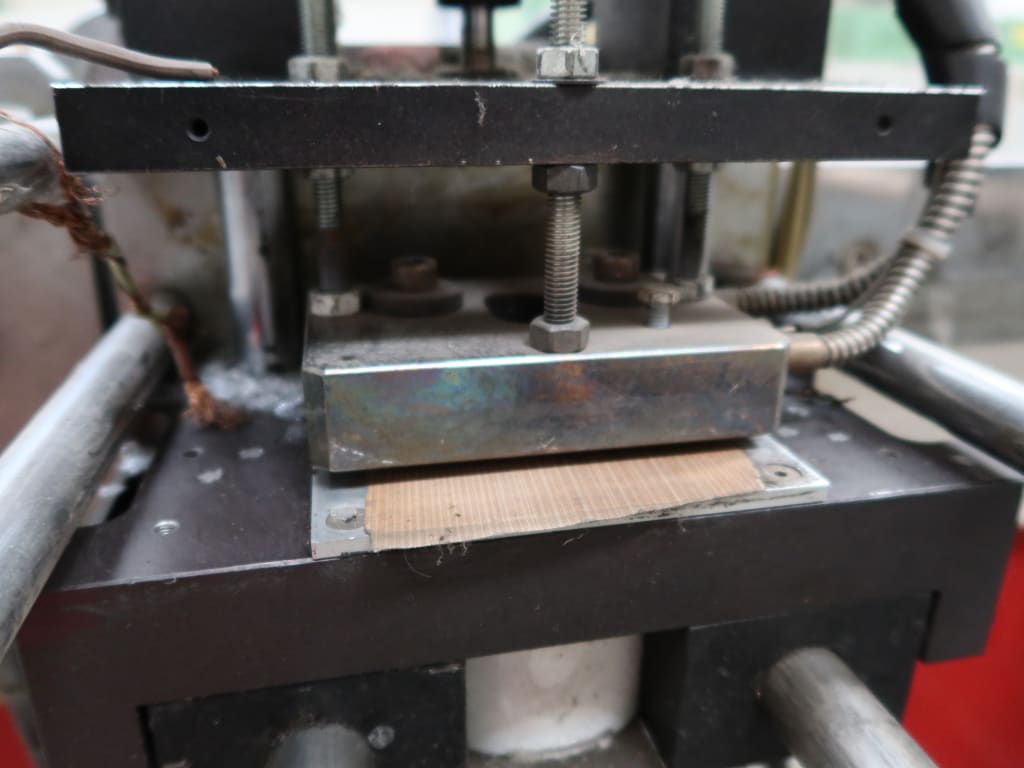

Handle Punching Machine for T-Shirt Bags

Pneumatic Handle Punching Press, Function: Cutting Carrying Handles (Die-Cut) In T-Shirt Bags After Bottom Sealing. Operation: Pneumatic, With Single Cutting Die. Existing Die Size: 110 × 120 mm, Integrated Electrical Cabinet With Emergency Stop And Control Panel, Remarks: Designed For Manual Feeding Of Stacks Of Pre-Welded Bags. Technical Data (Approx.): Cutting Stroke: Approx. 200 mm, Working Area: Approx. Diameter 600 mm, Typical Application: Handle Punching For LDPE/HDPE T-Shirt Bags. Overall Dimensions: L 900 × W 800 × H 1.600 mm. - LOT 12

![site]()

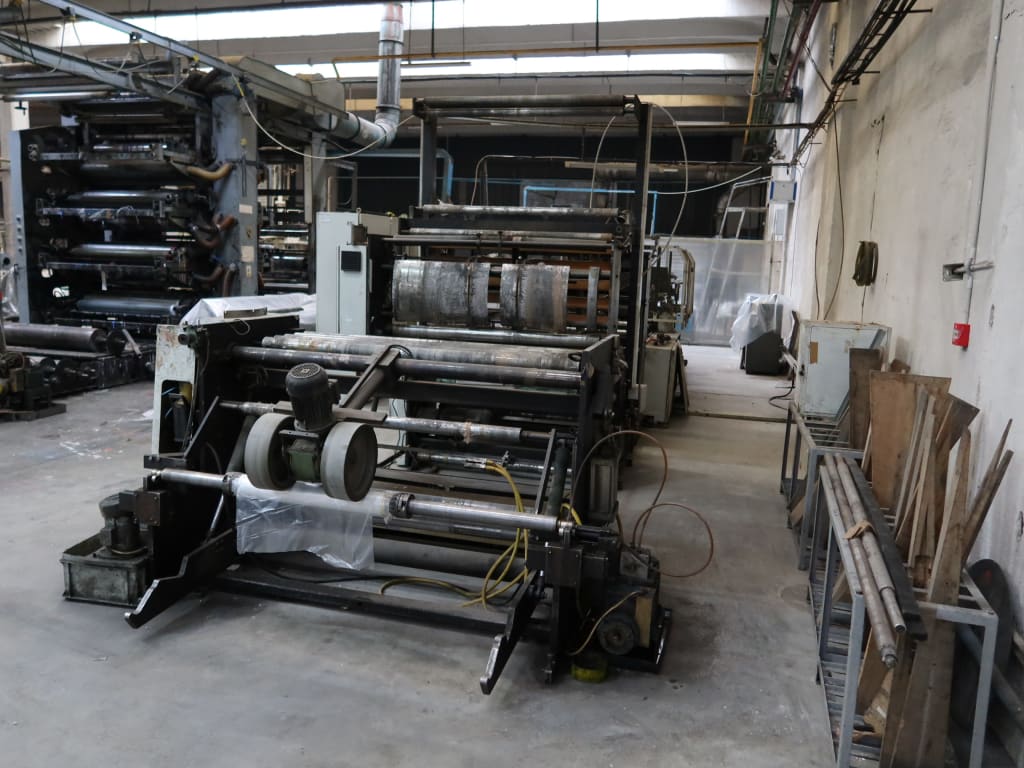

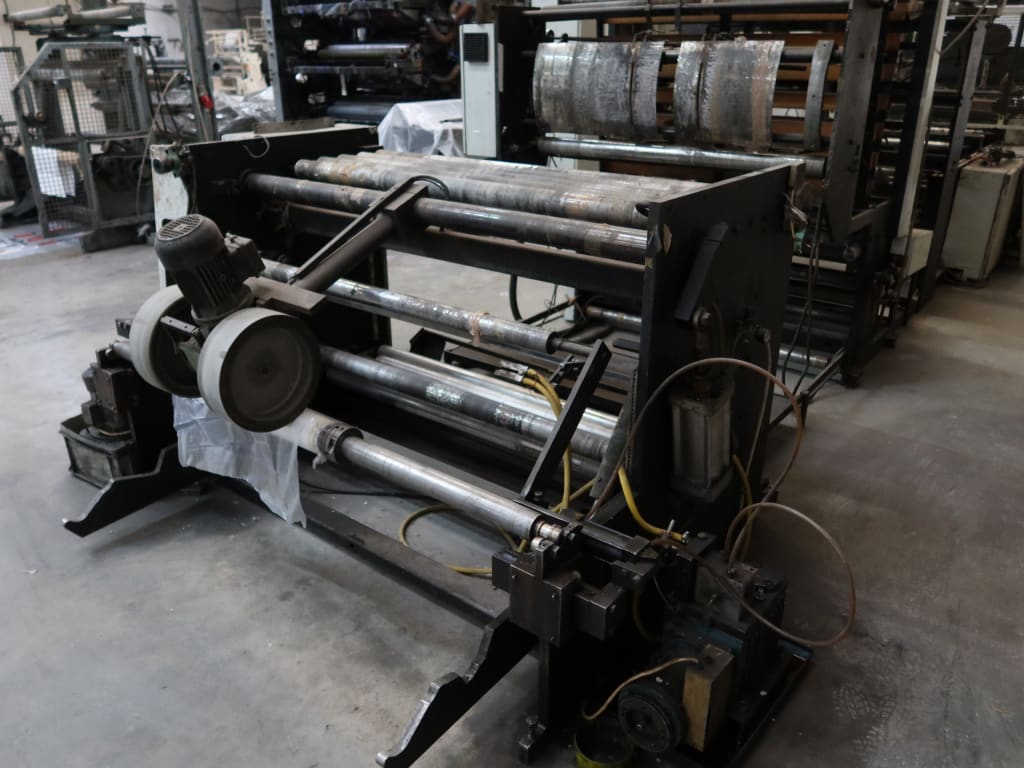

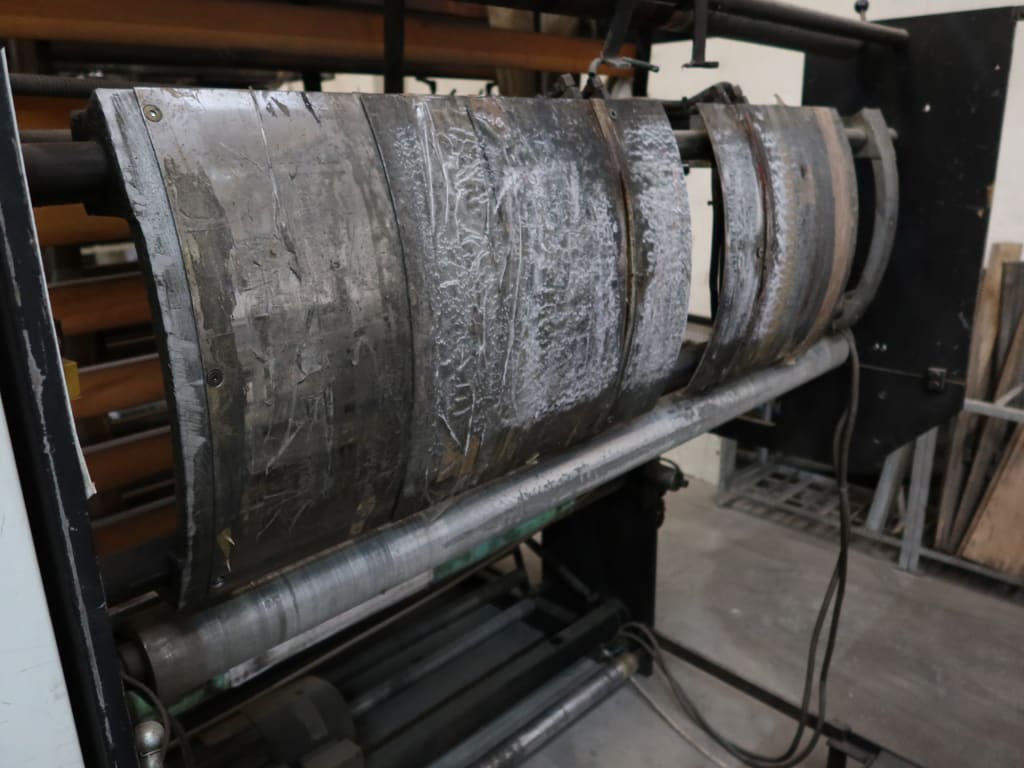

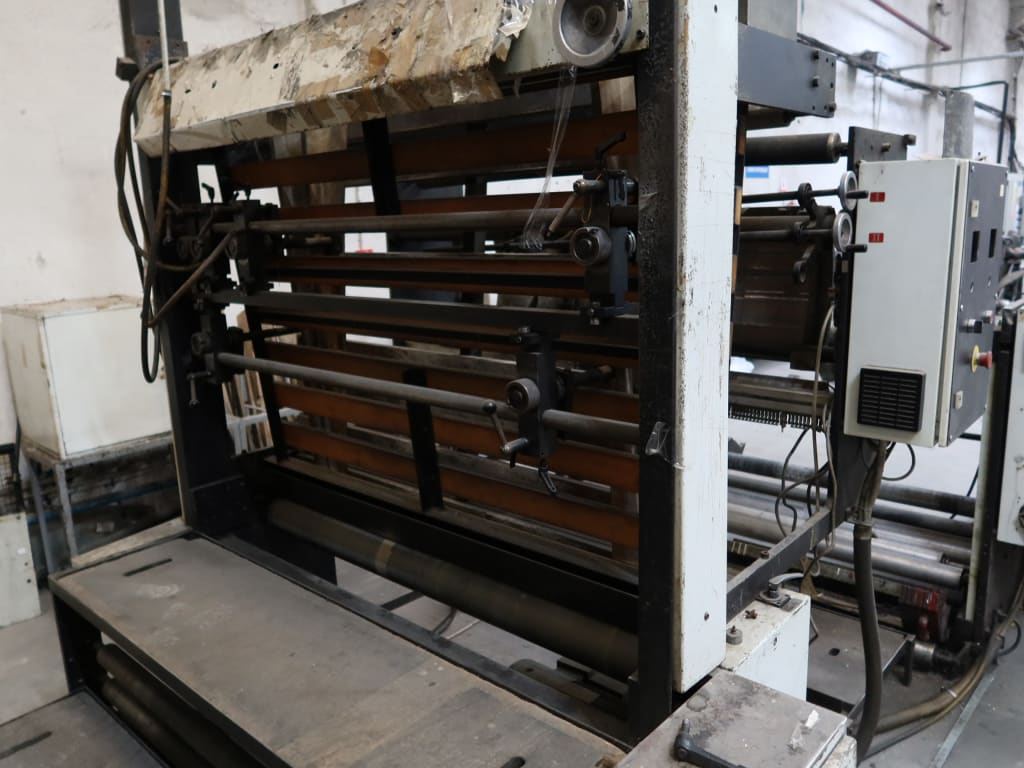

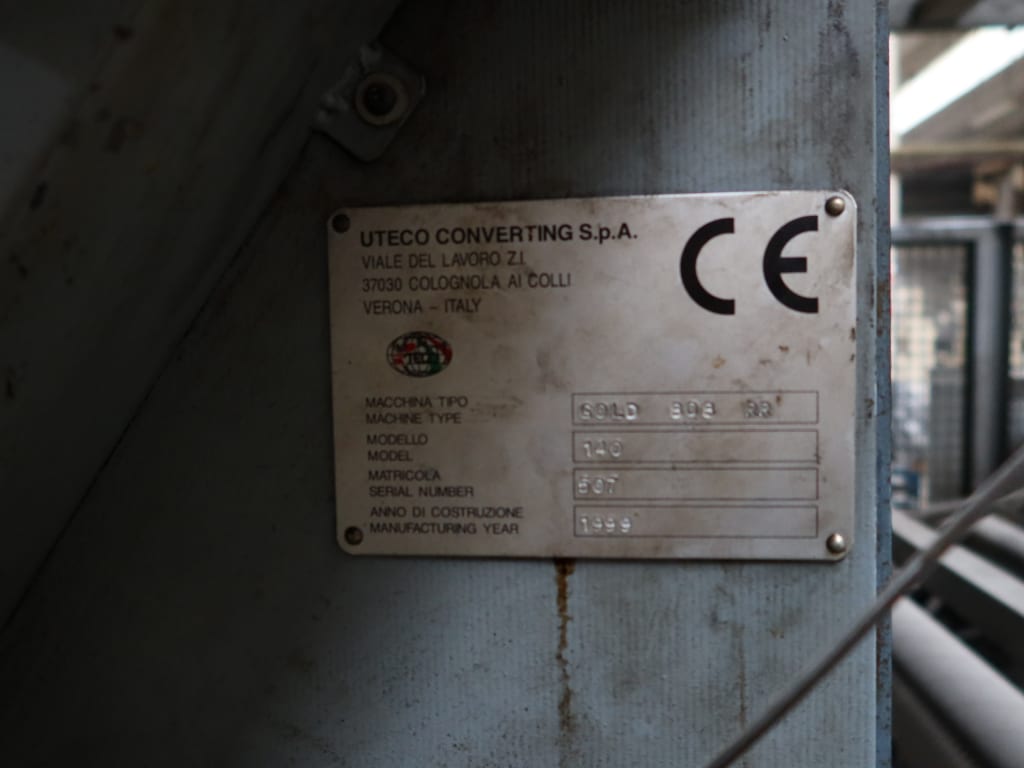

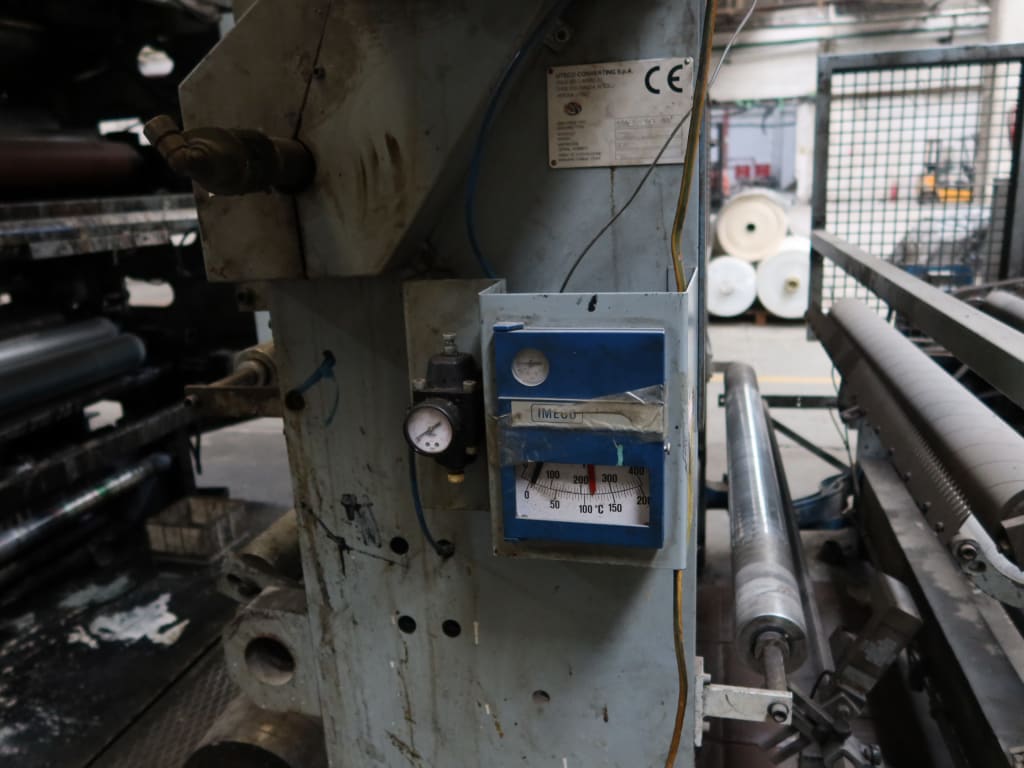

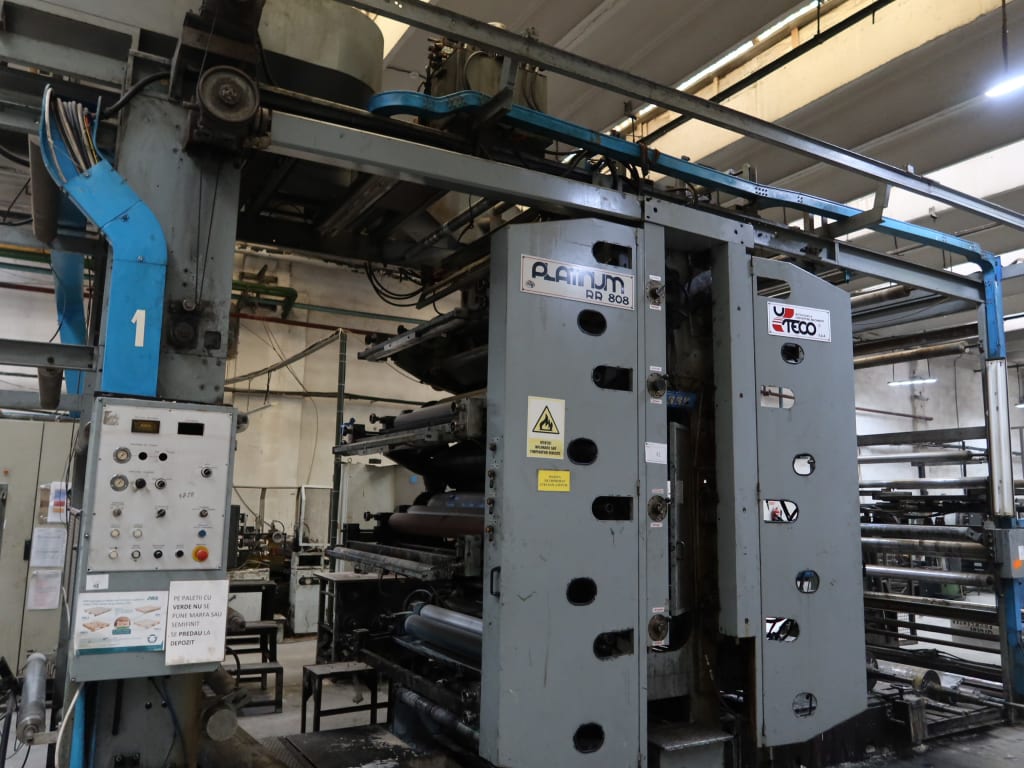

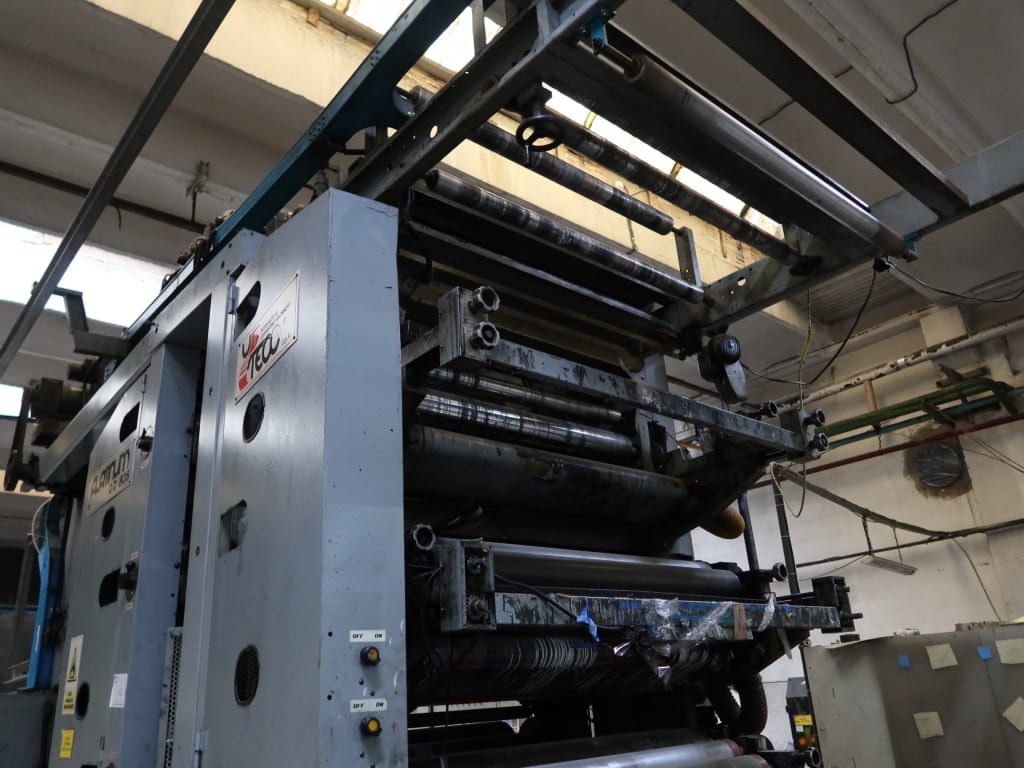

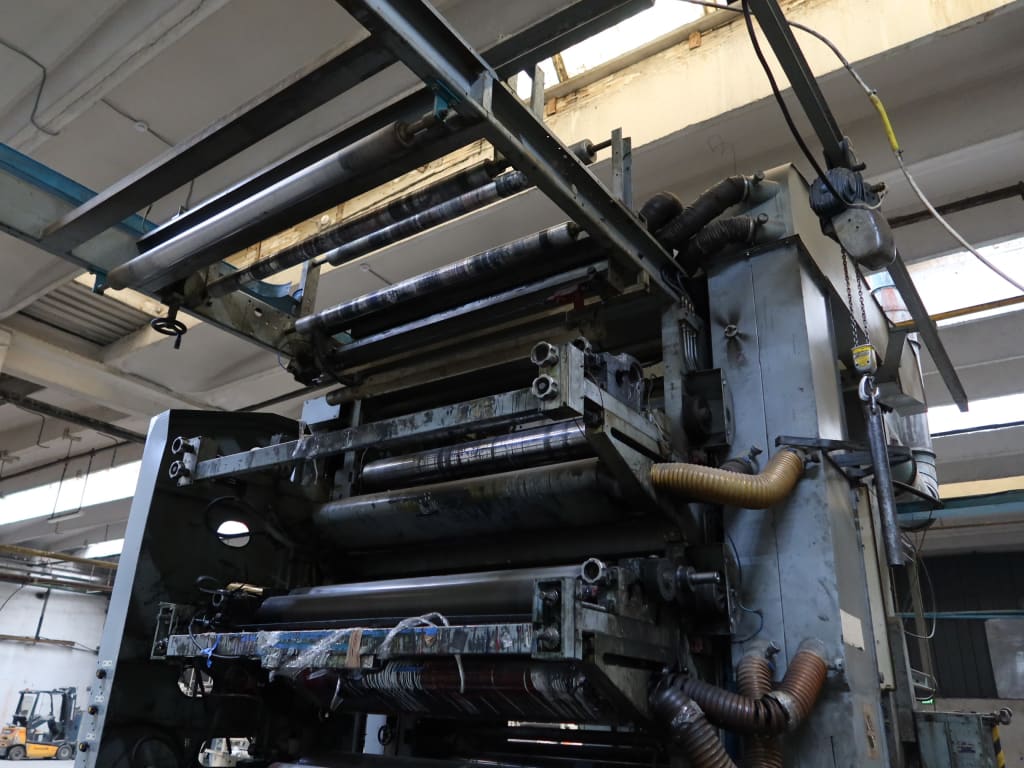

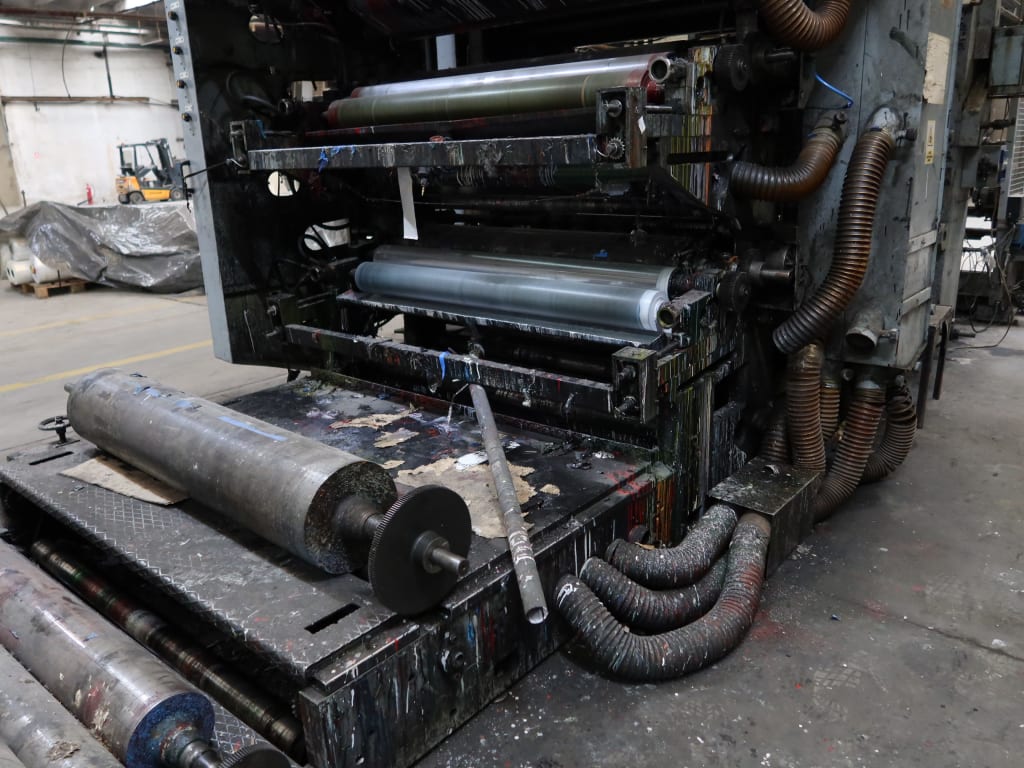

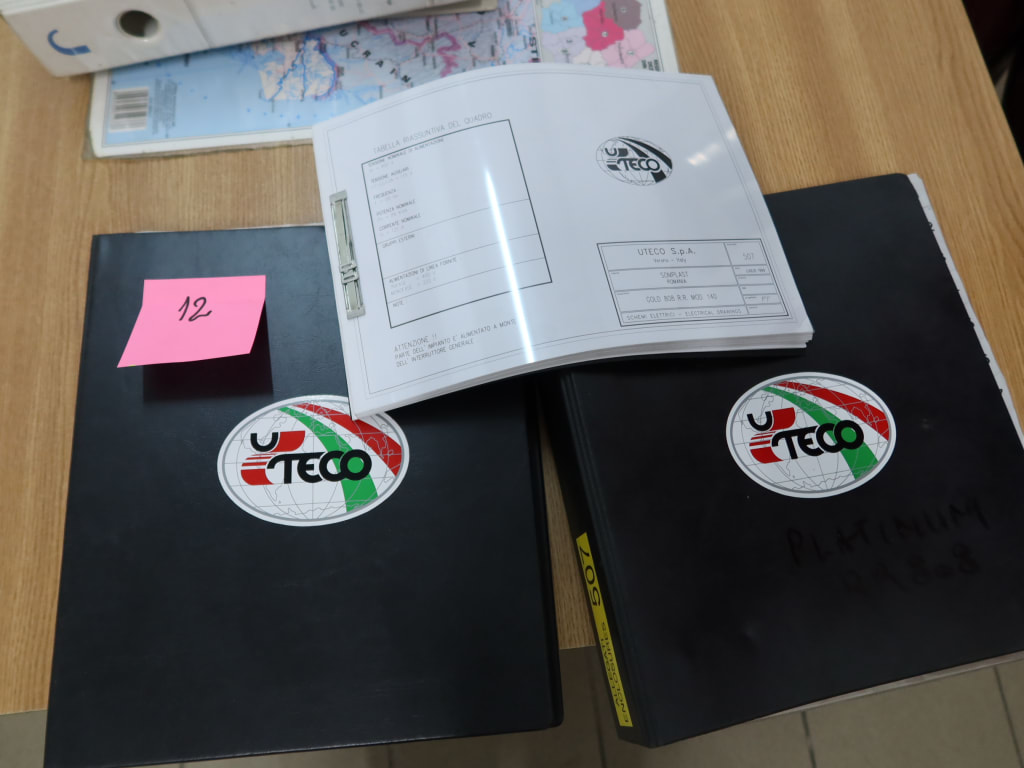

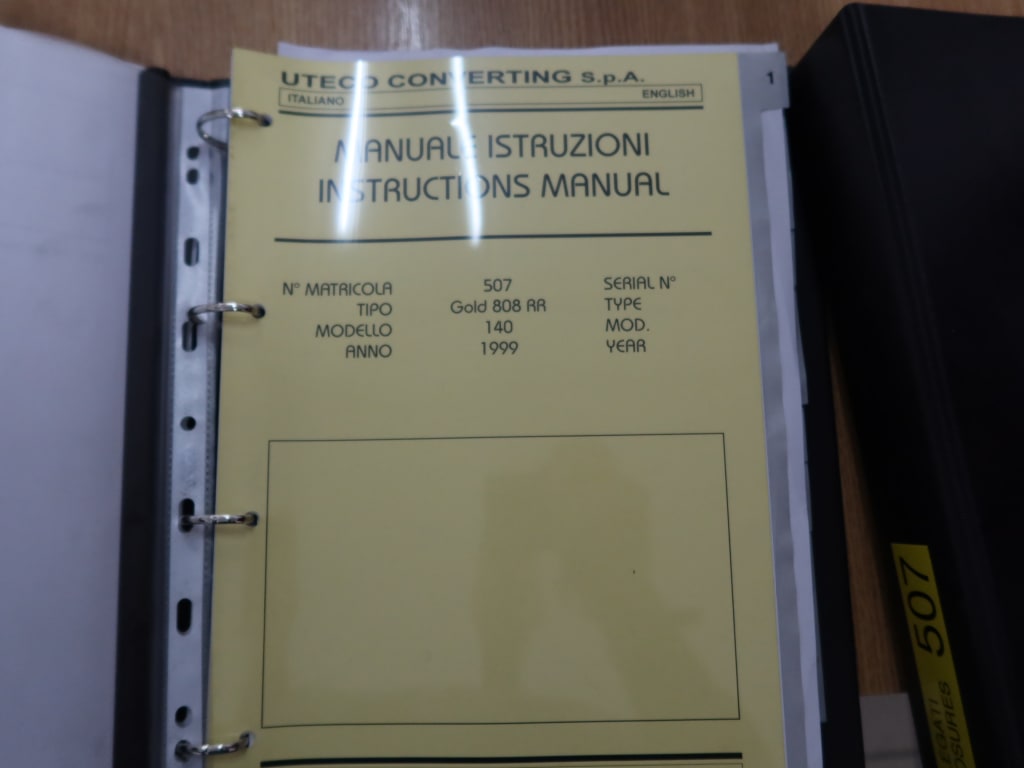

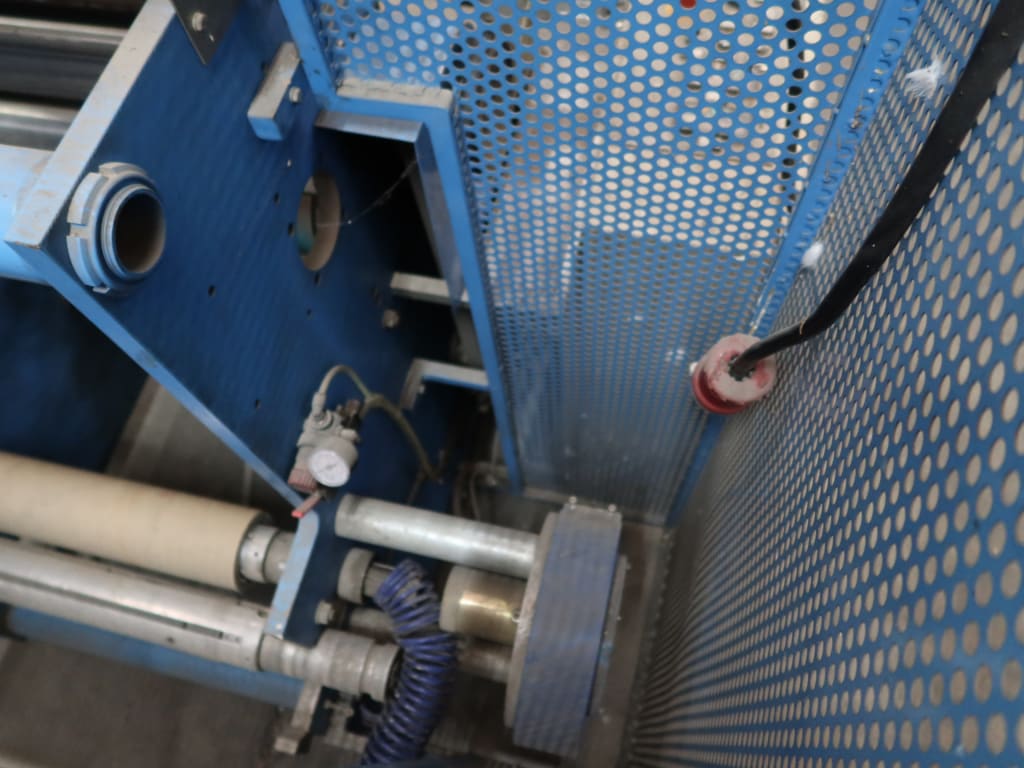

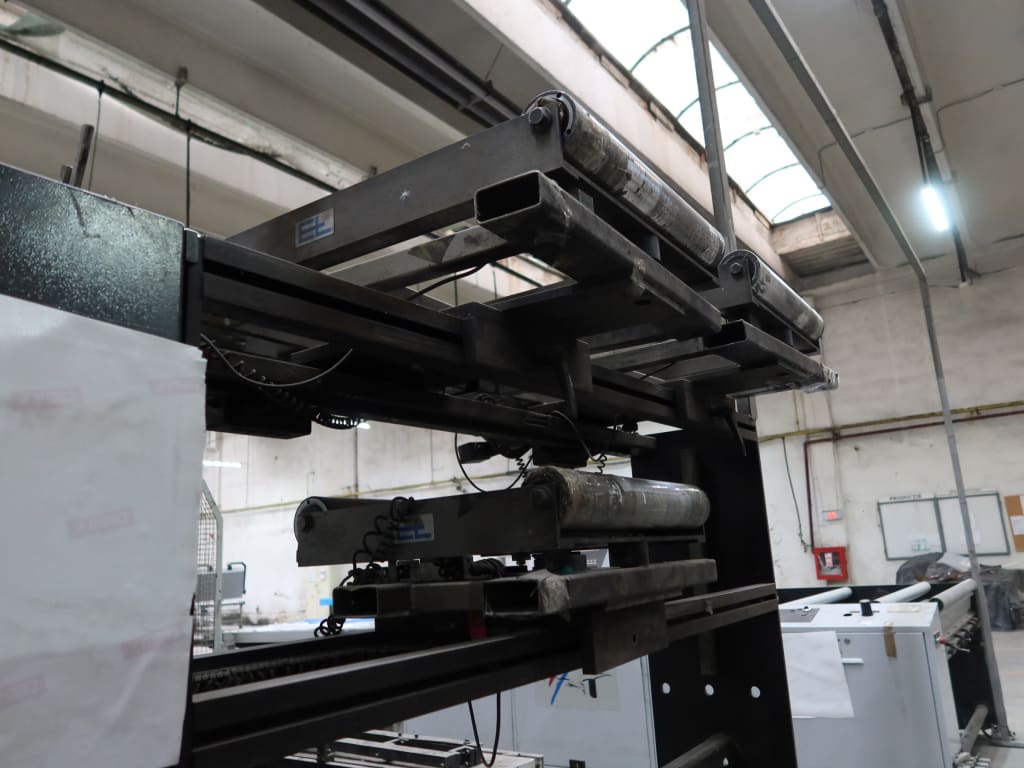

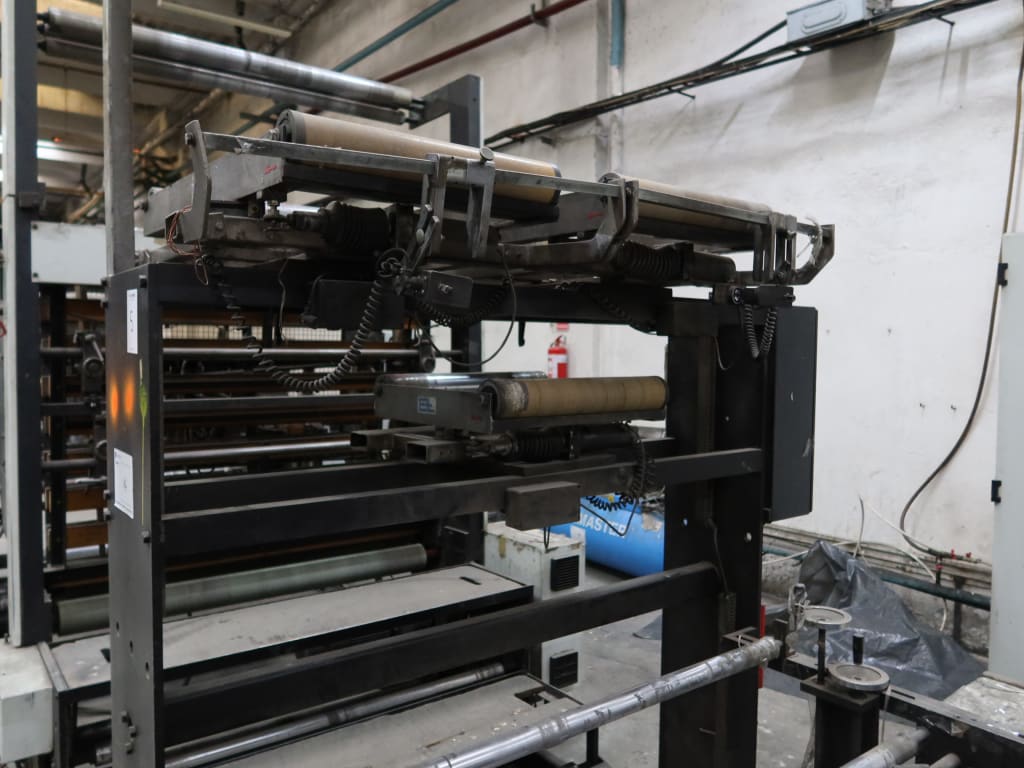

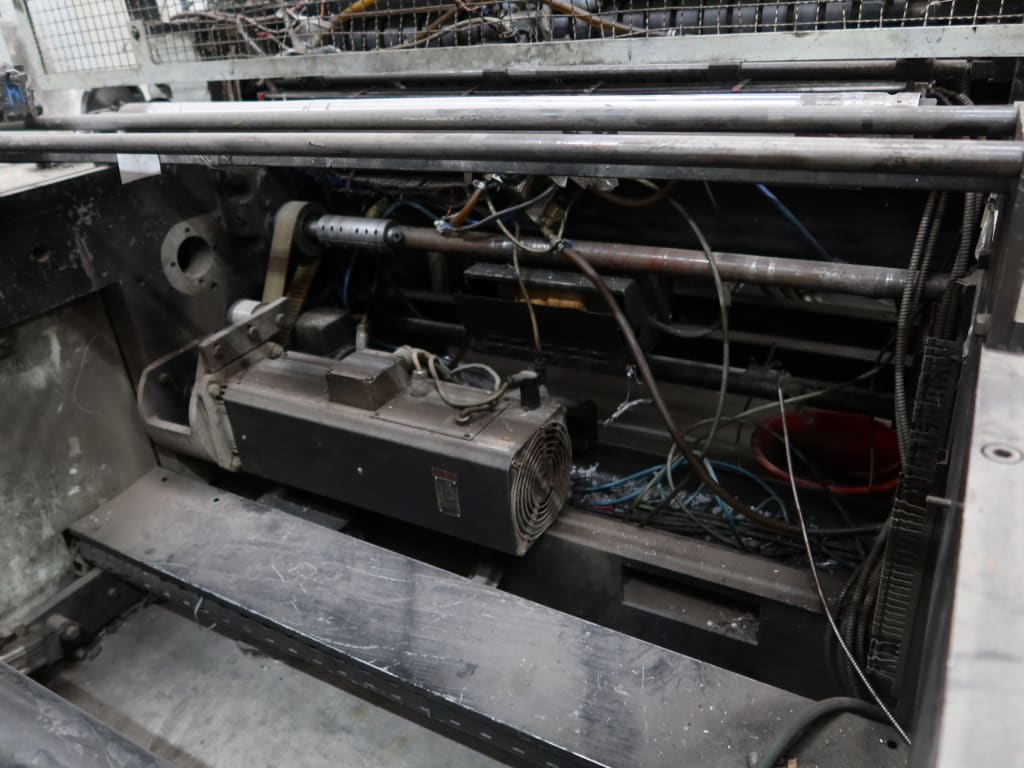

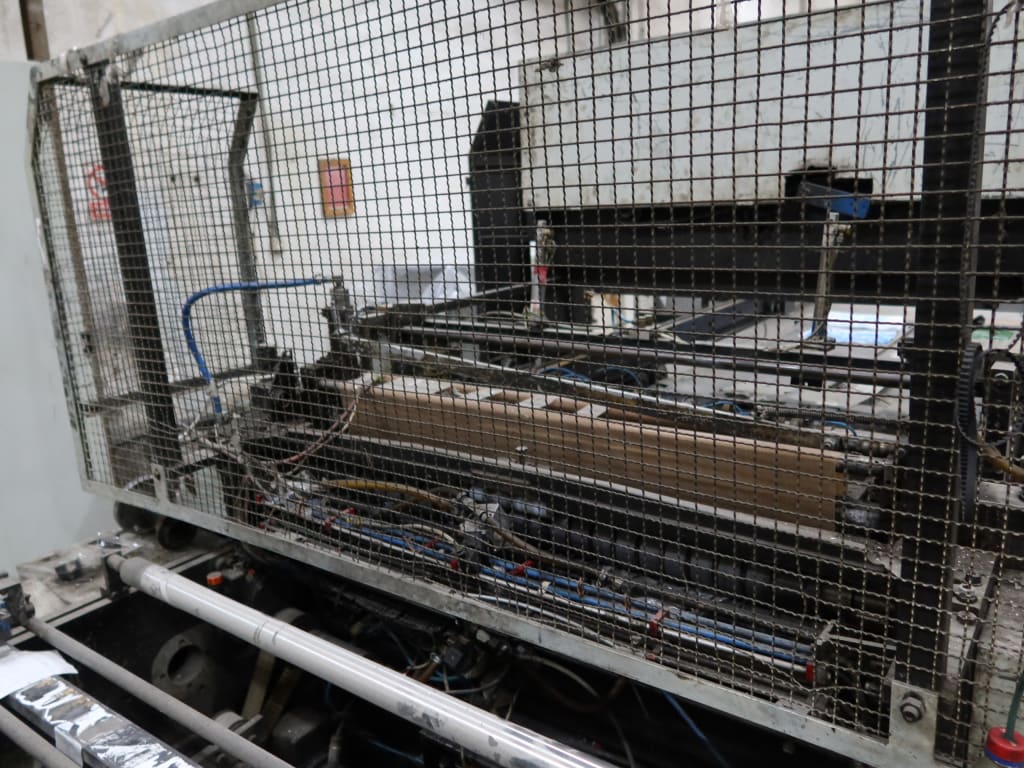

3 UTECO GOLD 808 AR Colour Flexographic Printing Presses (1999)

3 Colour Central Impression (CI) Printing Line, Comprising Of The Following Main Components, Printing Type: Central Impression Drum. Number Of Colours: 3. Printing Sides: Both Sides (2 Faces). Downstream & Auxiliary Equipment: Drying System: Gas-Heated Hot Air, Drive And Control: Individual Motor Drive With Inverter Control, Control Equipment: Electrical Cabinet (L 2.500 × W 800 × H 2.200 mm) And Operator Control Panel, Remarks: Designed For Flexographic Printing On Both Sides Of Film Web, Complete With Unwinder And Rewinder Units, Gas Drying System Integrated In Upper Section. Technical Data (Approx.): Printing Width: 1.400 mm, Web Width: Up To 1.400 mm, Printing Repeat Lengths: 320 / 390 / 440 / 490 / 590 / 690 / 870 mm, Suitable Materials: LDPE, HDPE, LLDPE, PP And Similar Flexible Films, Unwind/Rewind Diameter: Approx. 800 mm. Overall Dimensions: L 10.500 × W 3.000 × H 6.000 mm. - LOT 13

![site]()

IVR SAR50 R Film Rewinder/Unwinder Unit (2000)

Compact Film Winding Unit (Rewinder/Converter), Function: Used For Rewinding Or Converting Large Rolls Into Smaller Rolls. Adaptability: Adaptable For Cores Of Ø 76 mm And Ø 40 mm. Downstream & Auxiliary Equipment: Control Cabinet: Integrated Control Cabinet With Start/Stop And Speed Control, Features: Equipped With Manual Roll Loading And Tension Adjustment, Usage: Stand-Alone Machine For Auxiliary Use (Slitting, Rewinding, Or Inspection). Technical Data (Approx.): Maximum Film Width: 500 mm, Maximum Roll Diameter: 500 mm, Suitable For: LDPE / HDPE / LLDPE Film And Similar Flexible Materials. - LOT 14

![site]()

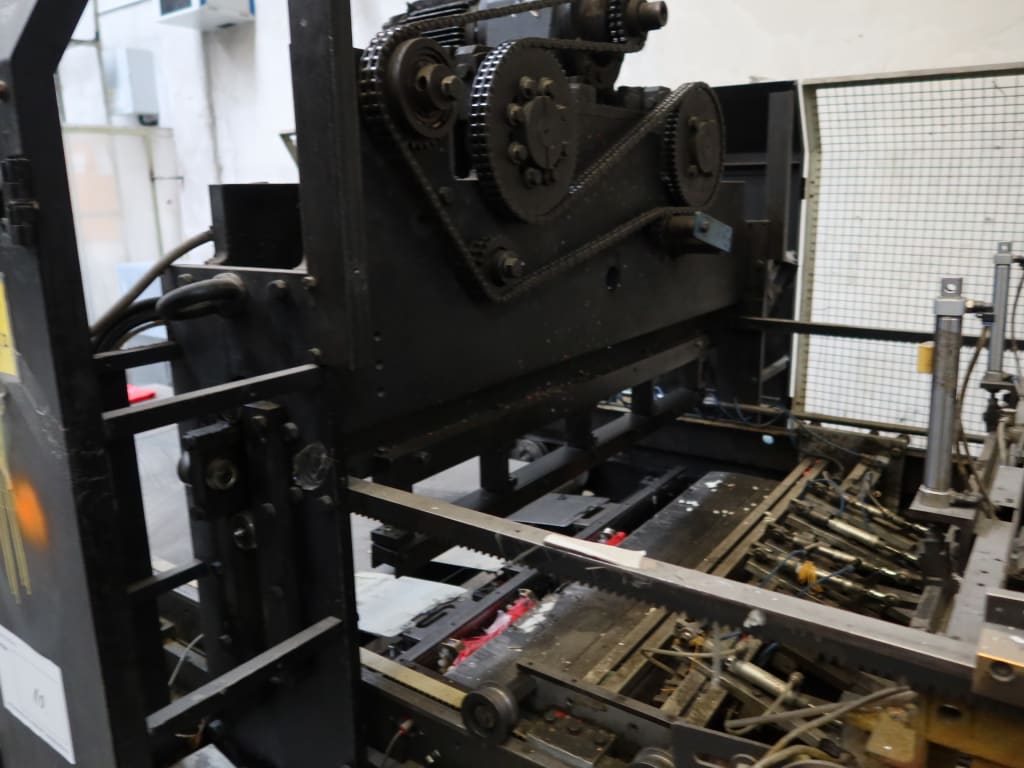

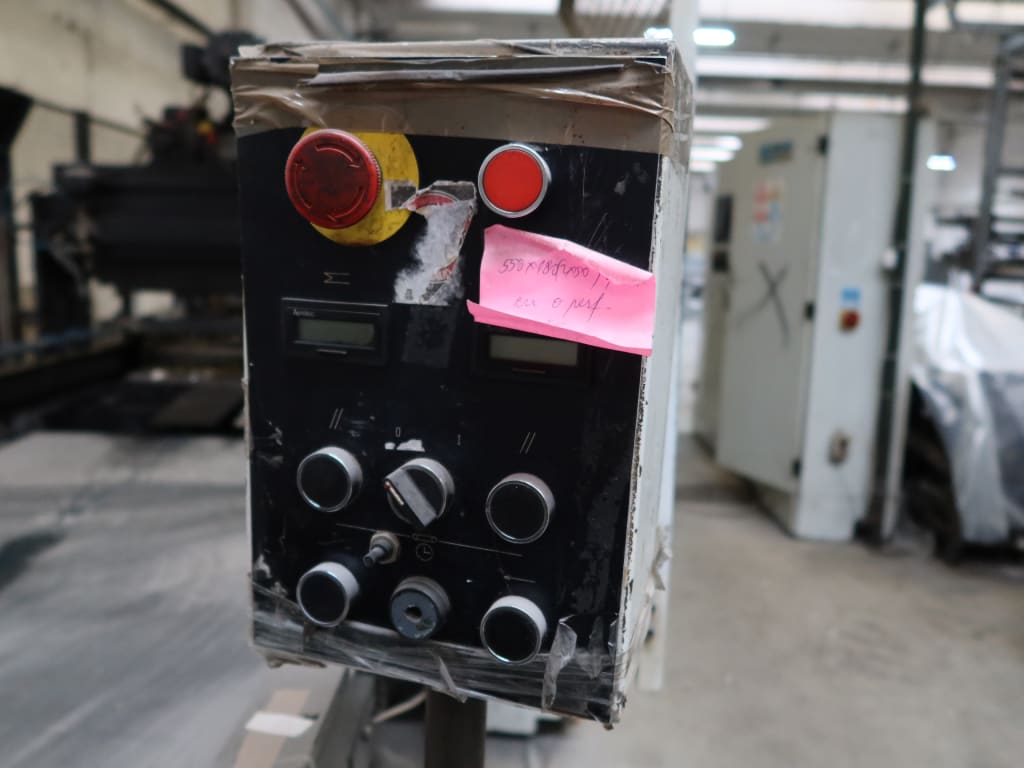

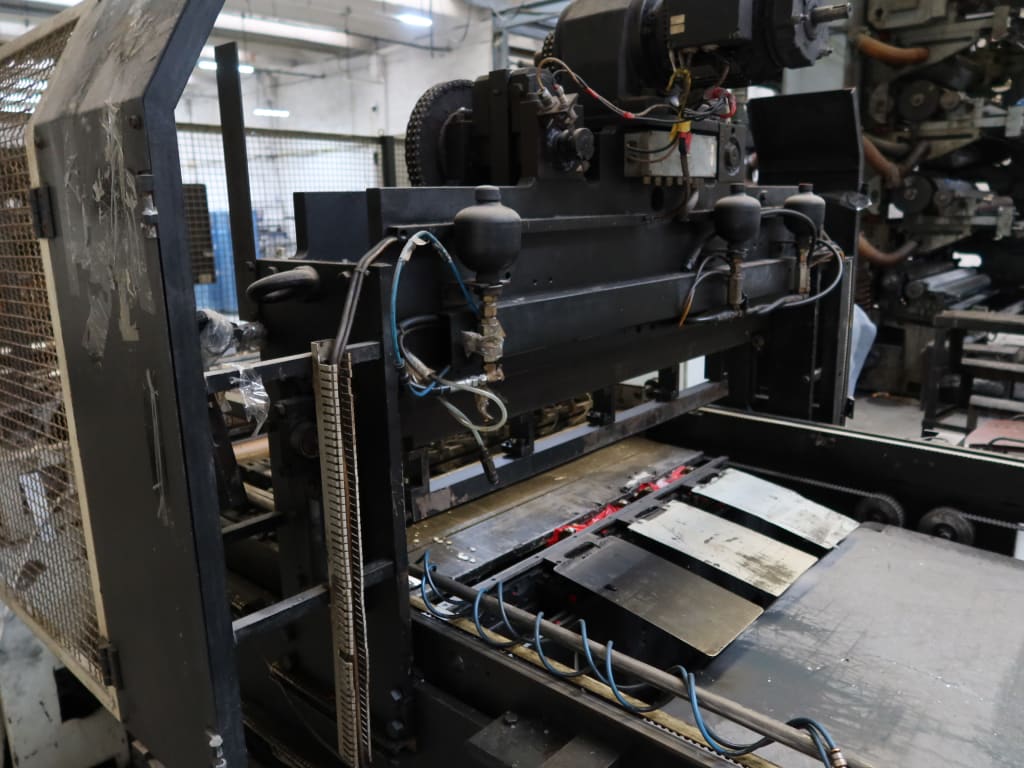

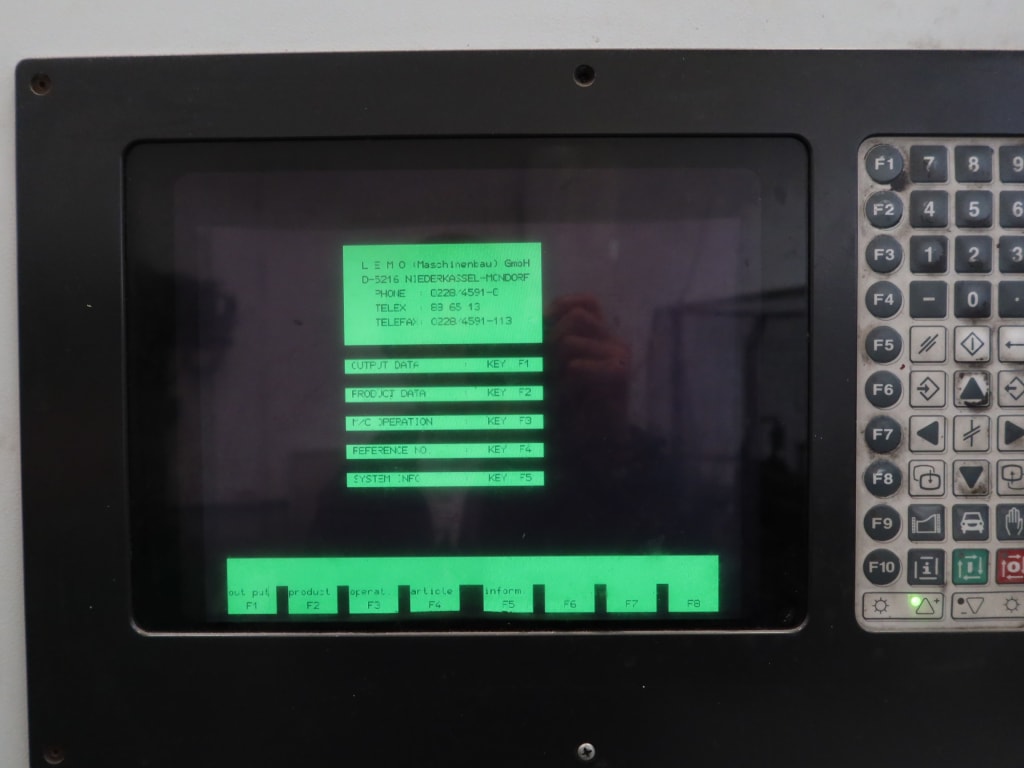

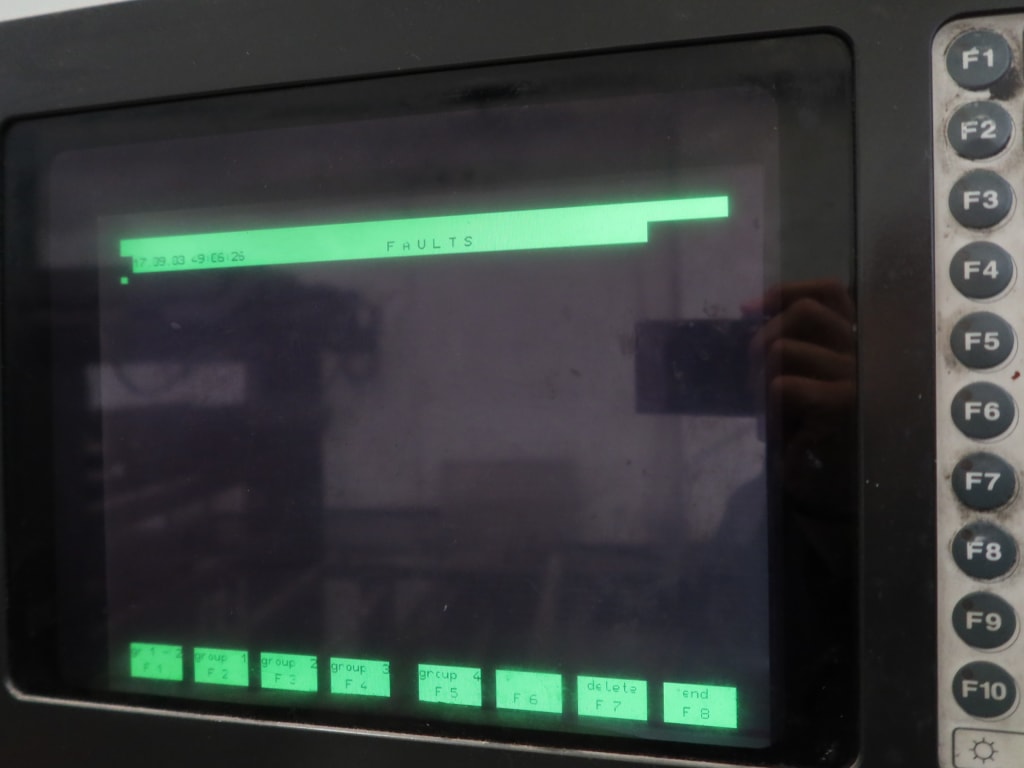

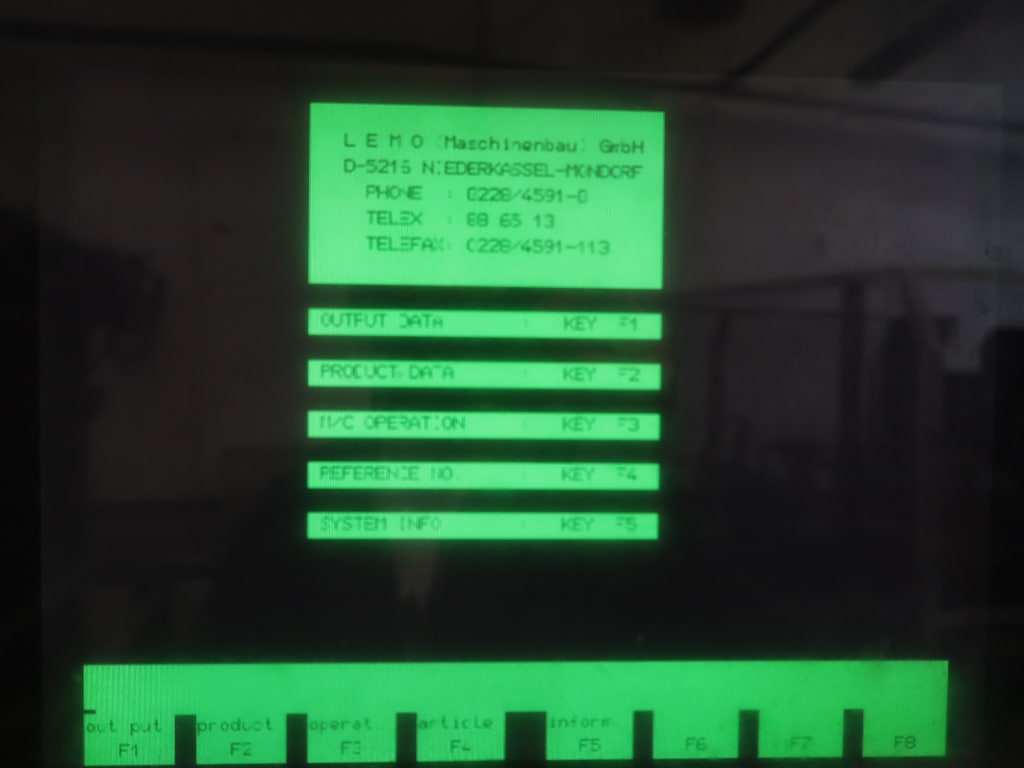

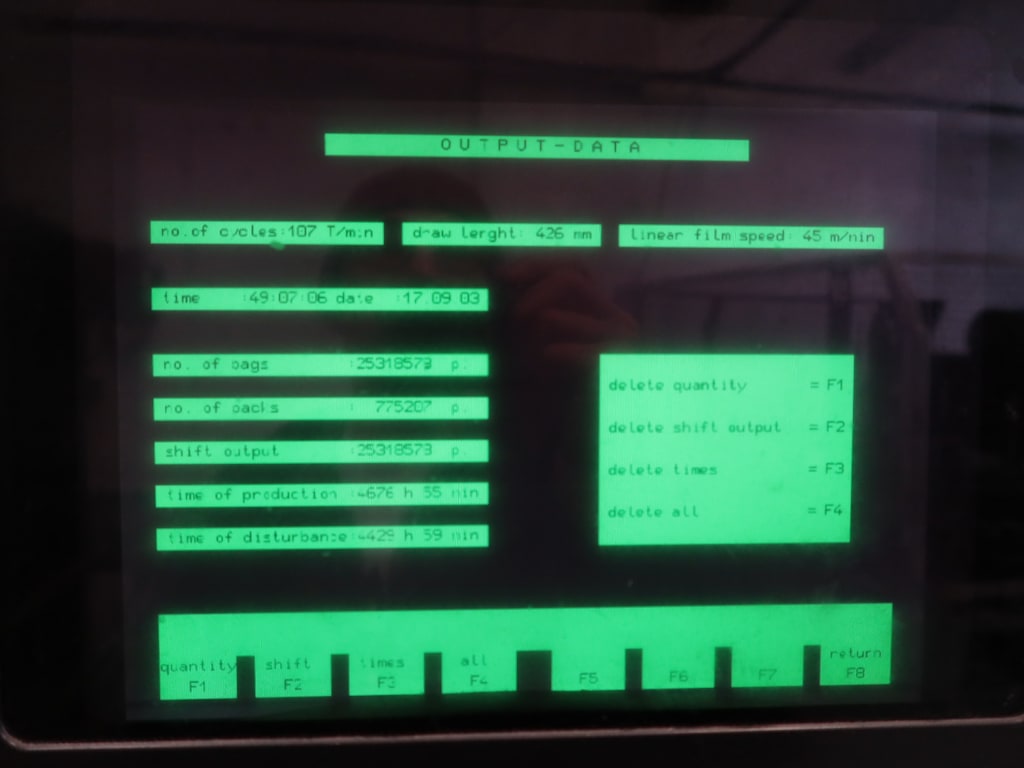

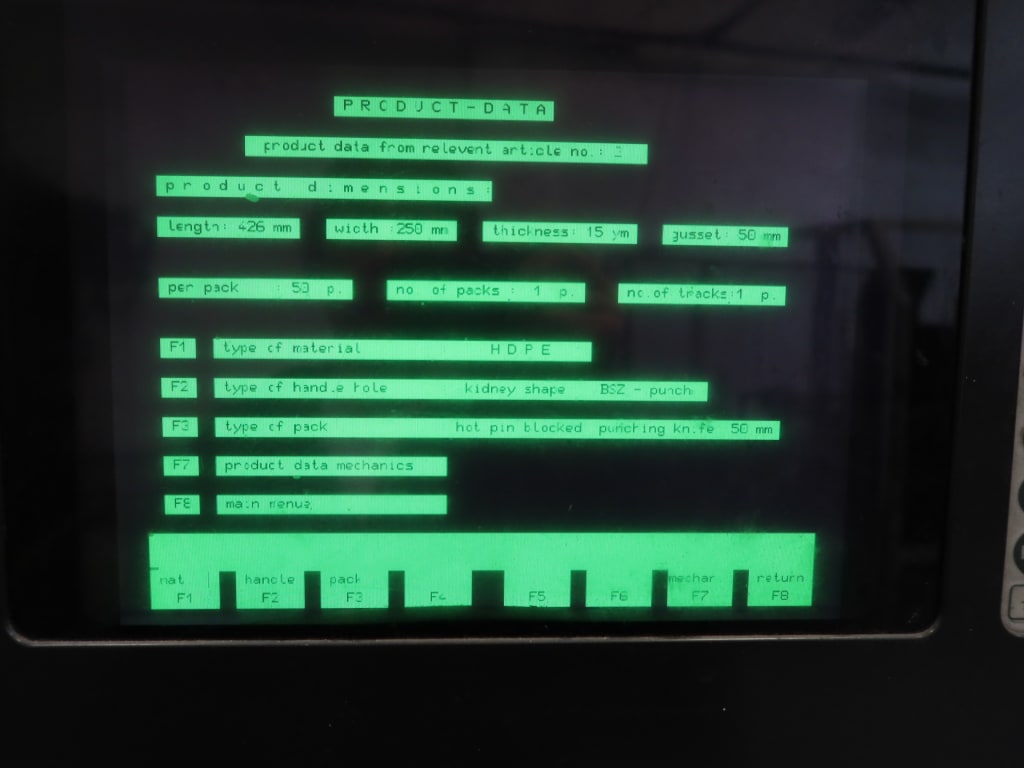

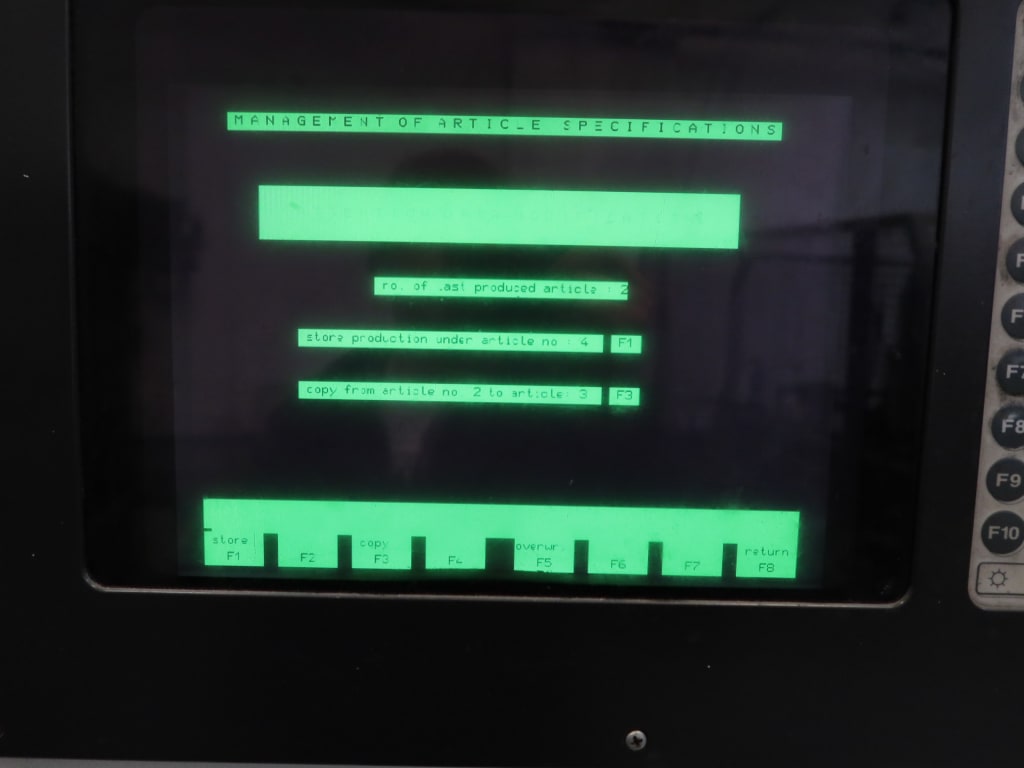

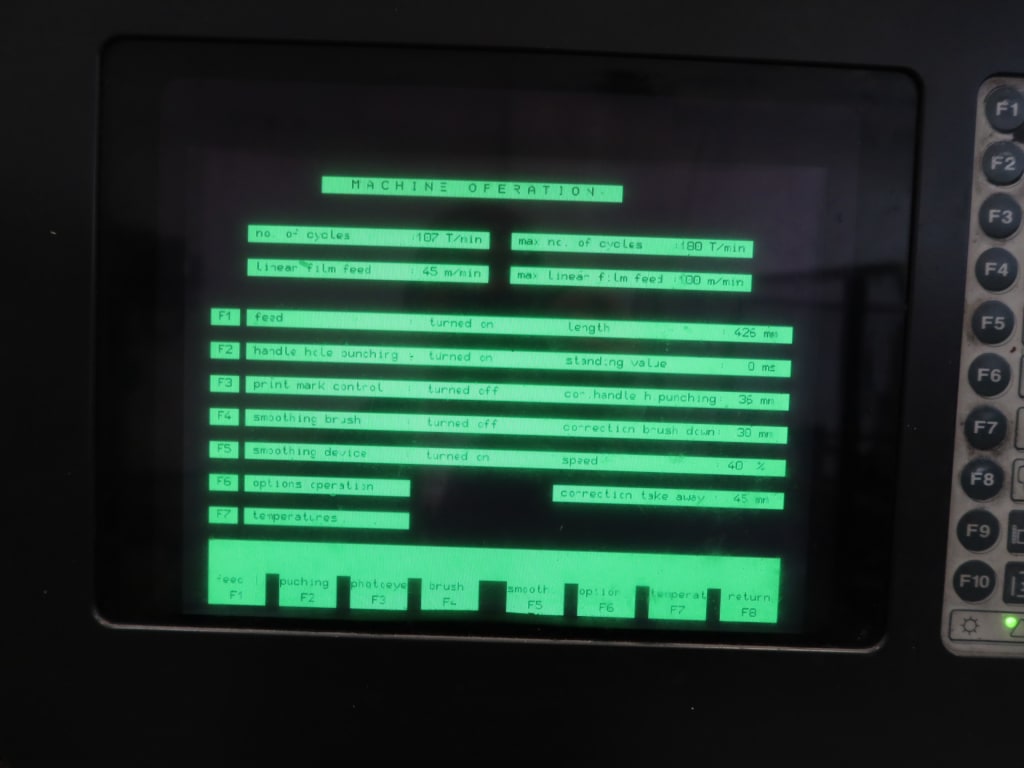

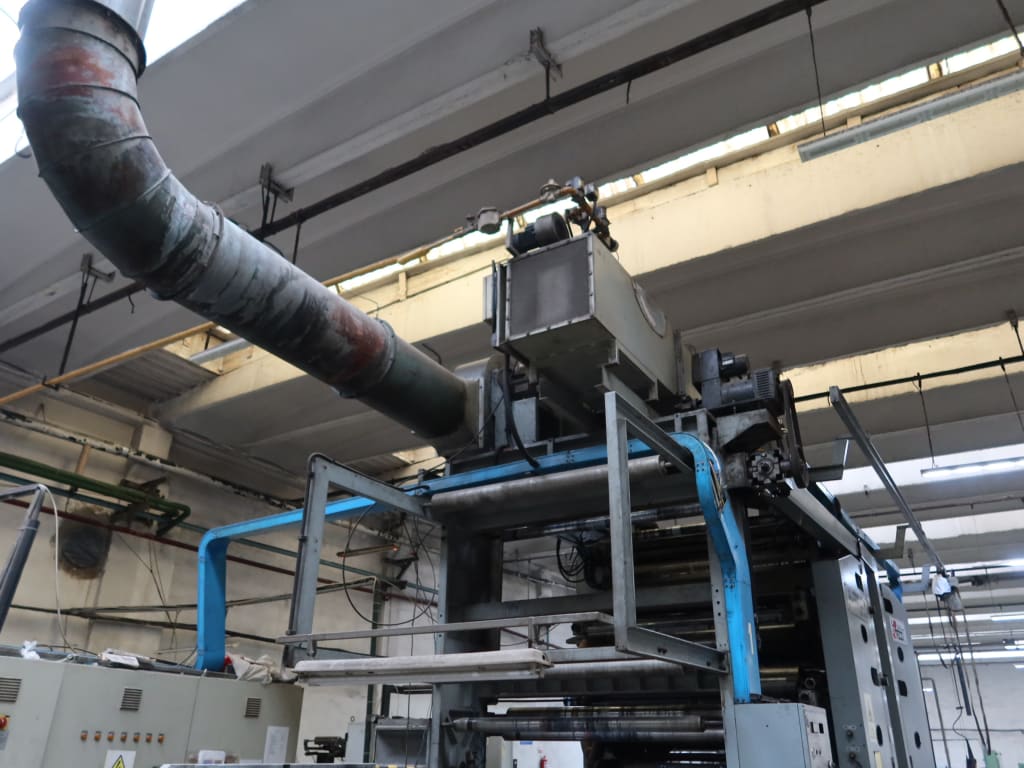

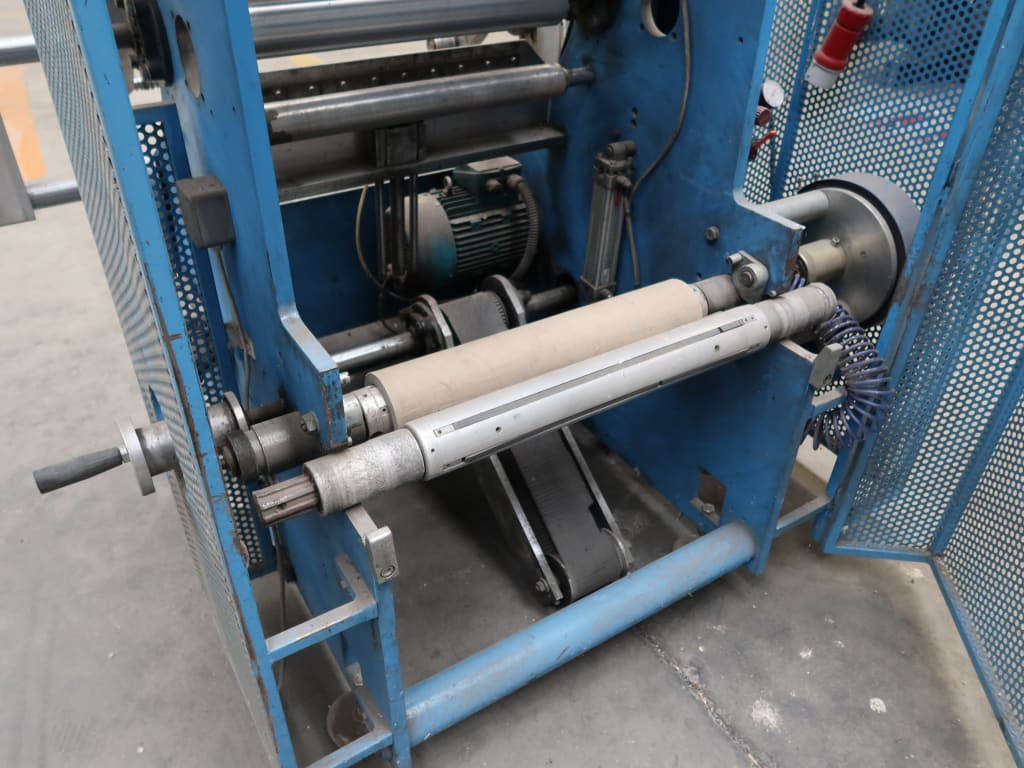

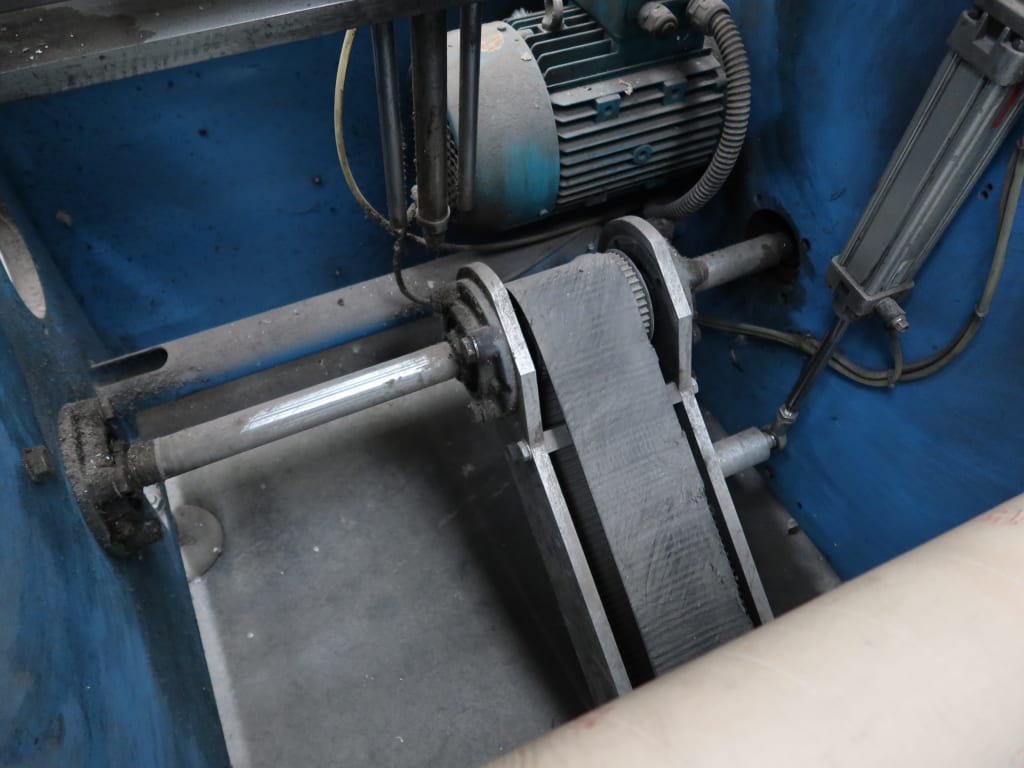

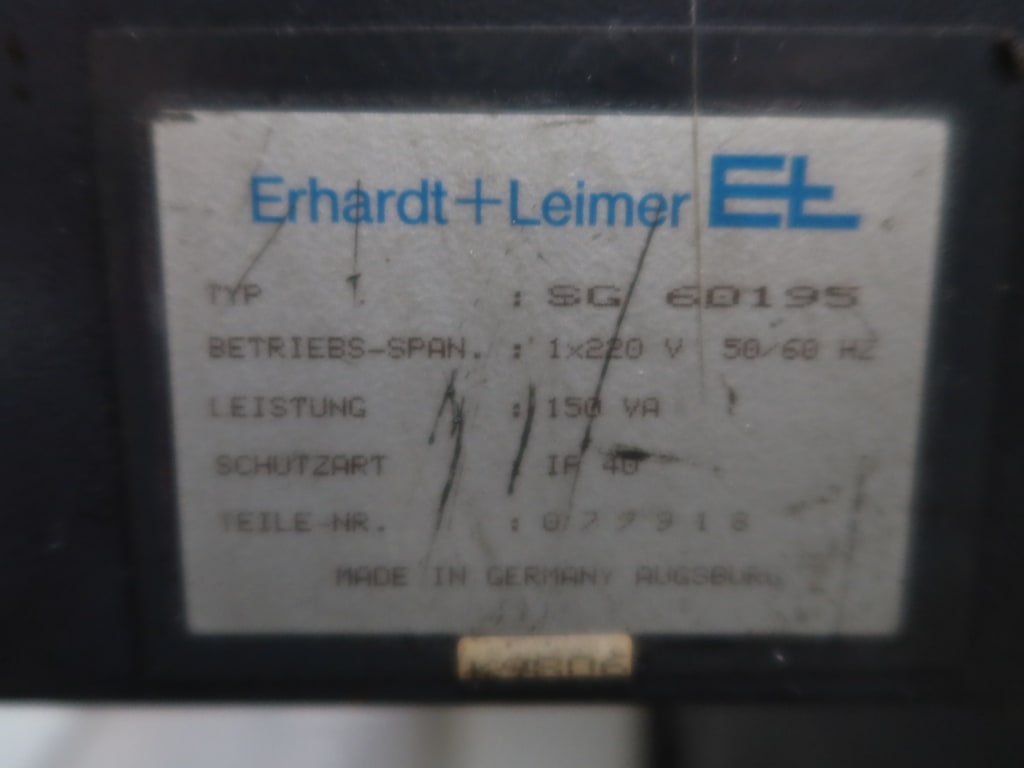

Lemo Maschinenbau GMBH Automatic Bag making Line (1993)

Automatic Line For Production Of Plastic Bags (Servo Drive, Web Guiding System), Comprising Of The Following Main Components, Unwinder: For Tubular Or Folded Film. Longitudinal Cutting Section: With 2 Knives (Splitting Into 3 Lanes). Longitudinal Welding Unit. Folding Station: With 4 Folds (Left/Right Max 100 mm). Downstream & Auxiliary Equipment: Lane Guiding System: EL, Bottom Sealing And Cutting Station: Thermal Weld, Transverse, Discharge Conveyor. Technical Data (Approx.): Web Guiding System: Erhardt+Leimer SG60195, Electrical Cabinet: Steuerungsbau APEL GmbH, Total Power 30 kW, 380 V, 63 A, Equipment Details: Line Equipped With Unwinder, Sealing And Cutting Station, And Conveyor Output, Documentation: Includes Original Technical Manuals From LEMO, Film/Product Design: Likely Designed For Flat Or T-Shirt Bags Made From LDPE / HDPE Film, Bags Length: 300 – 700 mm, Bags Width: 150 – 300 mm. Overall Dimensions: L 11.000 × W 2.500 × H 2.500 mm. Electrical Cabinet Dimensions: L 2.500 × W 600 × H 2.200 mm. - LOT 15

![site]()

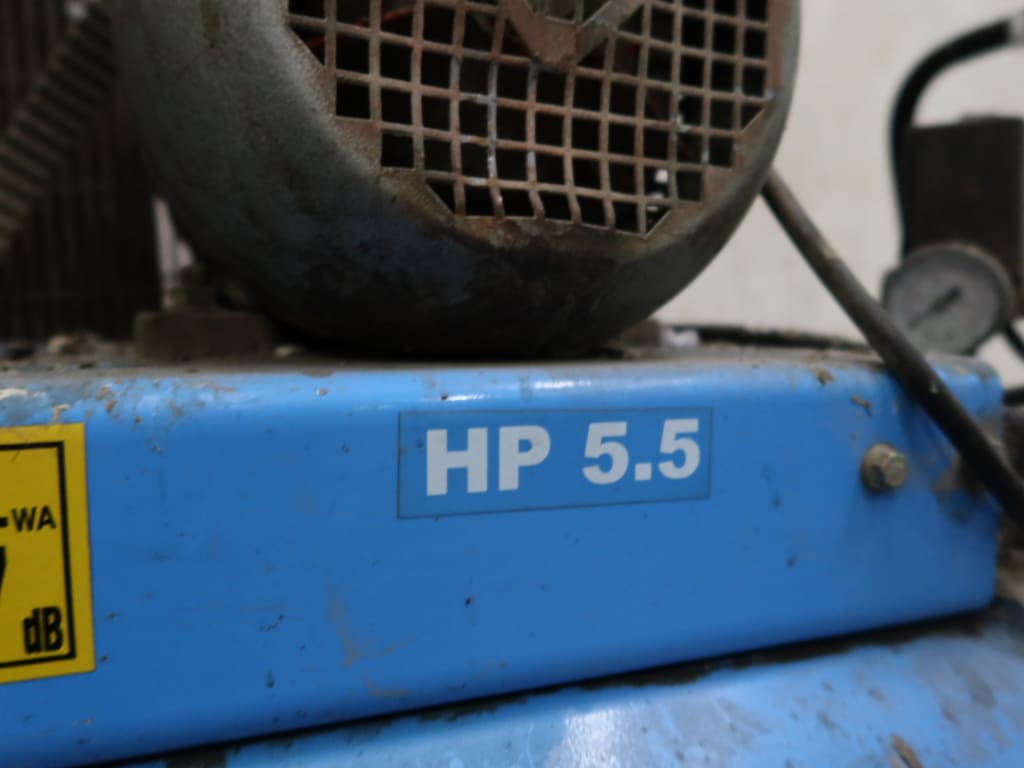

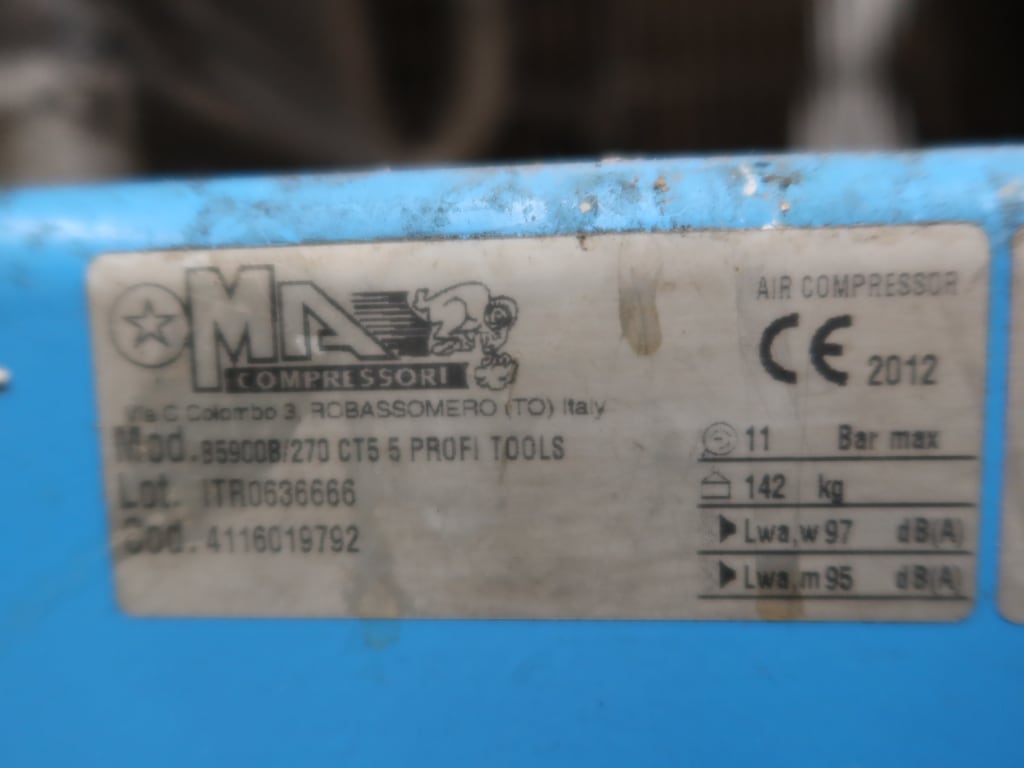

Airmaster B5900B/270 Air compressor (2012)

Maximum pressure: 11bar; Tank capacity: 270L; Motor power: 5.5 HP (4 kW); Weight: 142 kg; Noise Level: 95-97 dB(A); Configuration: Twin cylinder, belt driven, mounted on air receiver - LOT 16

![site]()

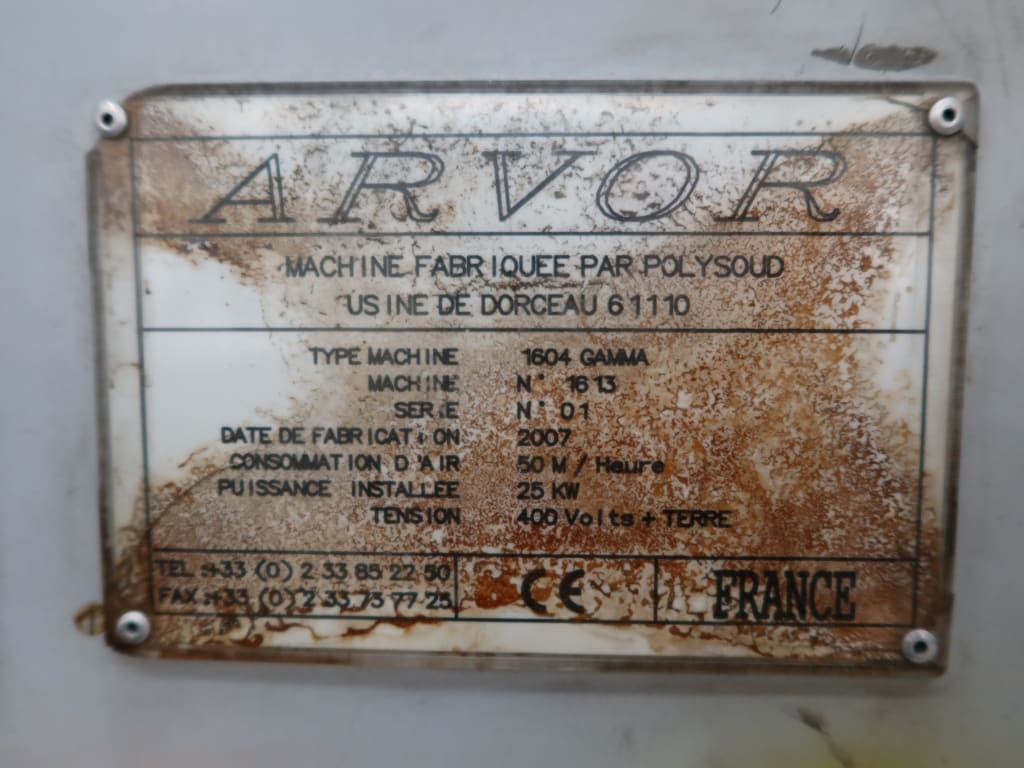

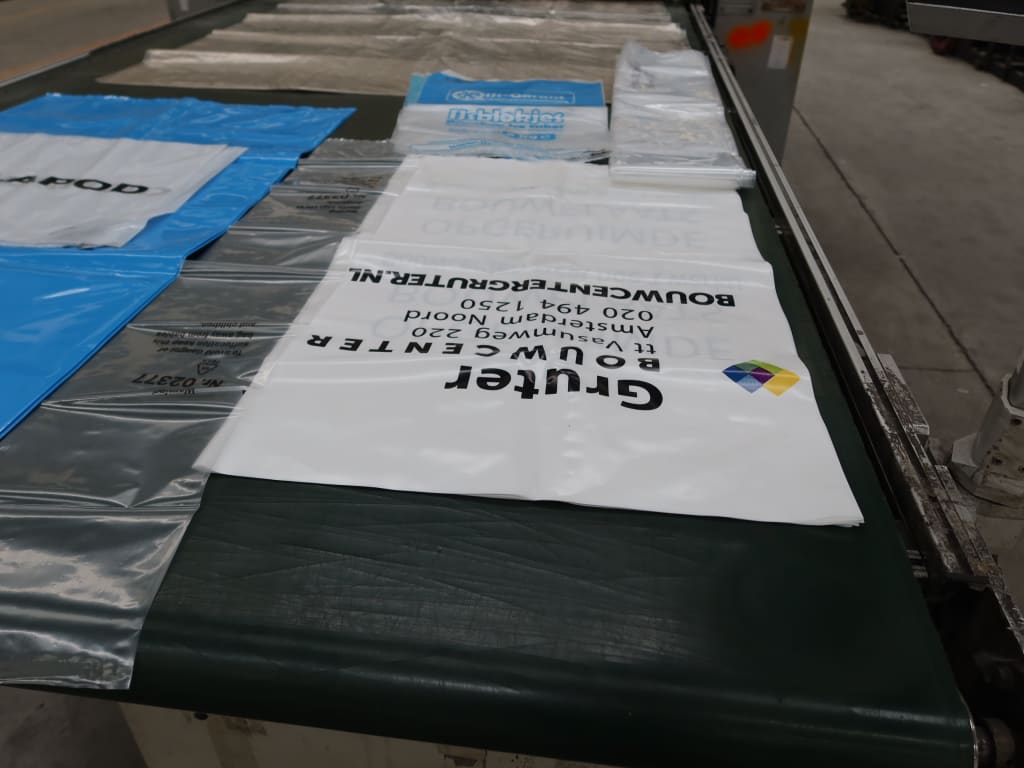

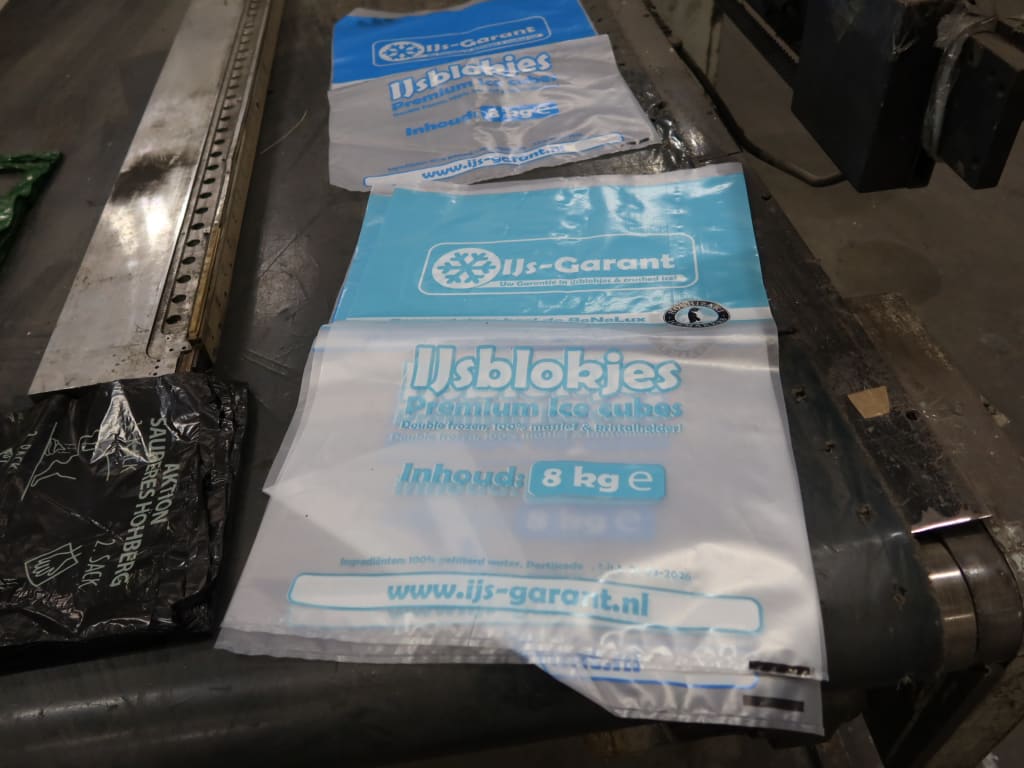

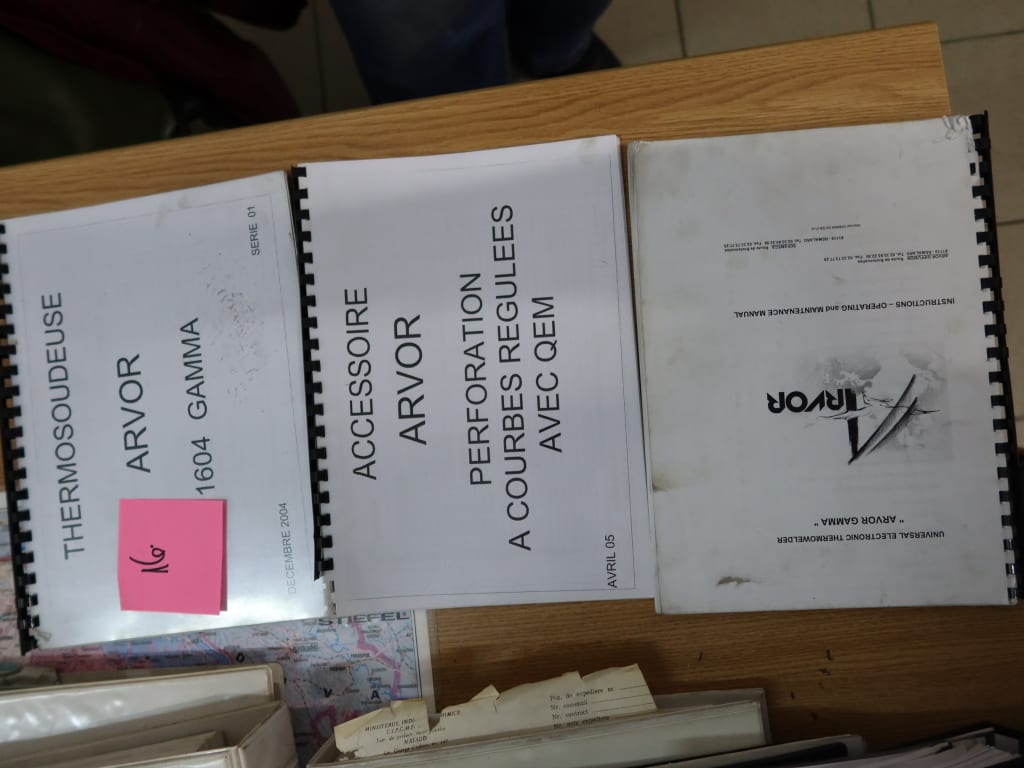

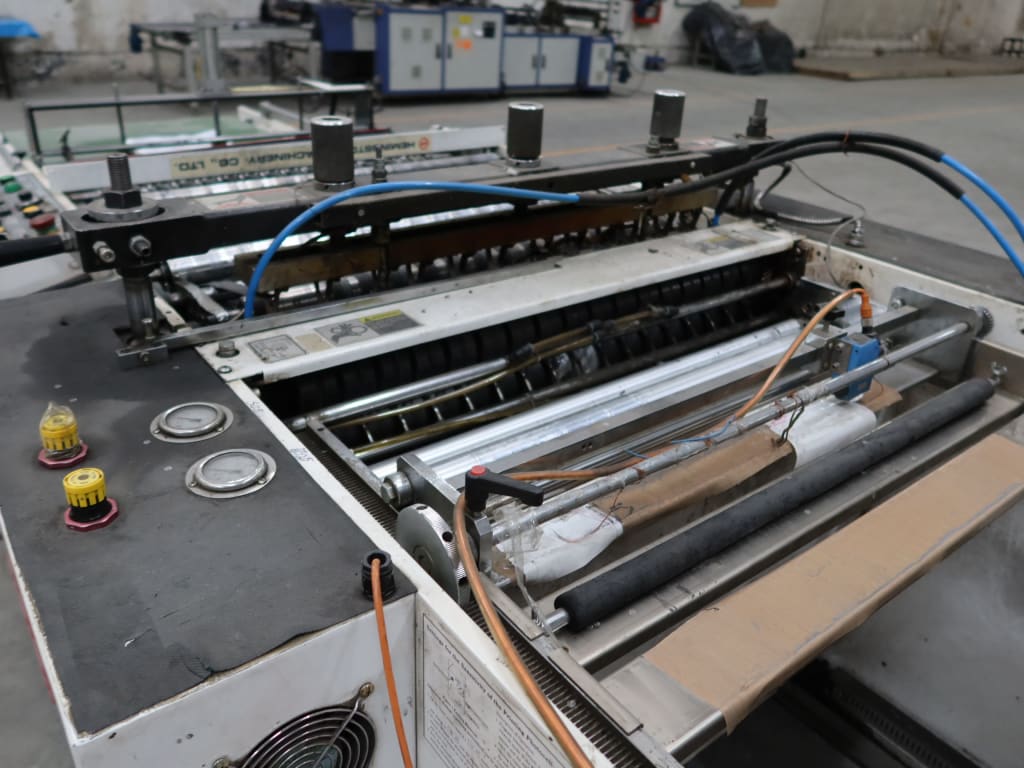

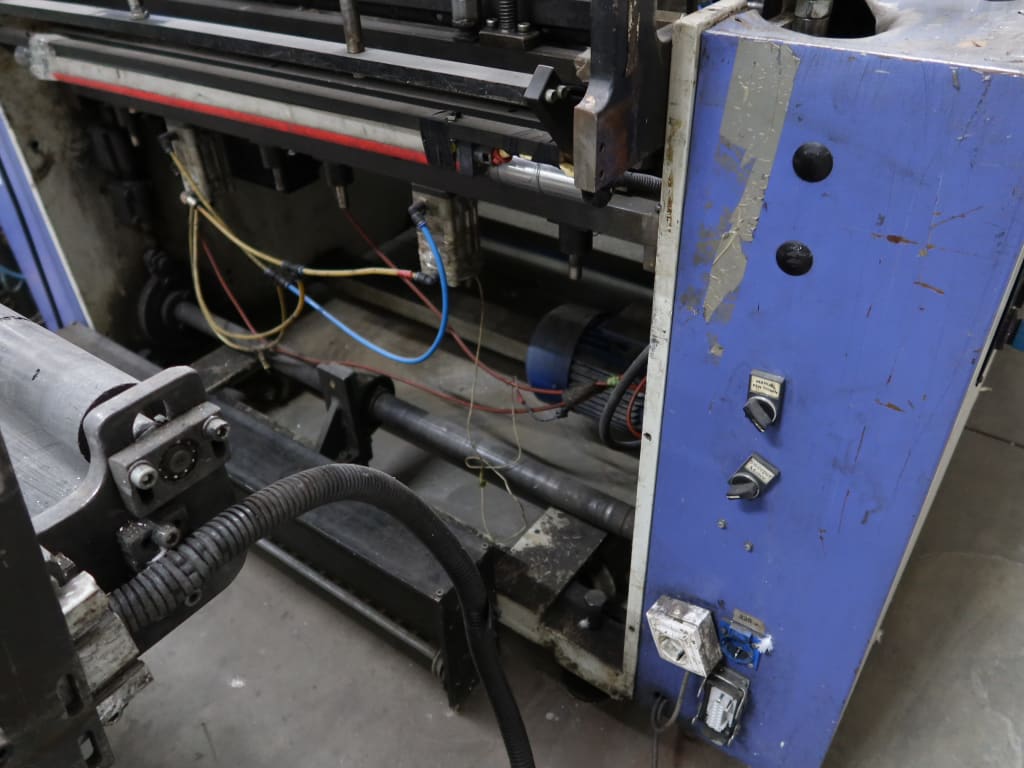

ARVOR Perfo BF/NP 03 Bag-Making Machine (2007)

Bag Making/Converting Line (Thermal Cutting And Sealing), Input Section: Double Unwinder For Two Tracks. Film Roll Width: Max 1.400 mm. Downstream & Auxiliary Equipment: Process: Thermal Cutting And Sealing, With Ballet-Type Outfeed System And Take-Off Conveyor, Perforation System: 8 mm Diameter, With 4 Perforation Devices (Max 32 Points), Additional Equipment: One Electrode Welding Unit For Thick Film, Supplied On Separate Pallet. Technical Data (Approx.): Working Width: Up To 1.500 mm, Operation: Single Or Dual Track (2 × 700 mm), Film Thickness: Up To 200 µm, Output Bag Dimensions: Width: 150 – 1.400 mm, Length: 200 – 3.500 mm, Installed Power: 40.5 kVA, Voltage: 400 V + N + PE. Overall Dimensions: L 9.000 × W 2.500 × H 1.500 mm. - LOT 17

![site]()

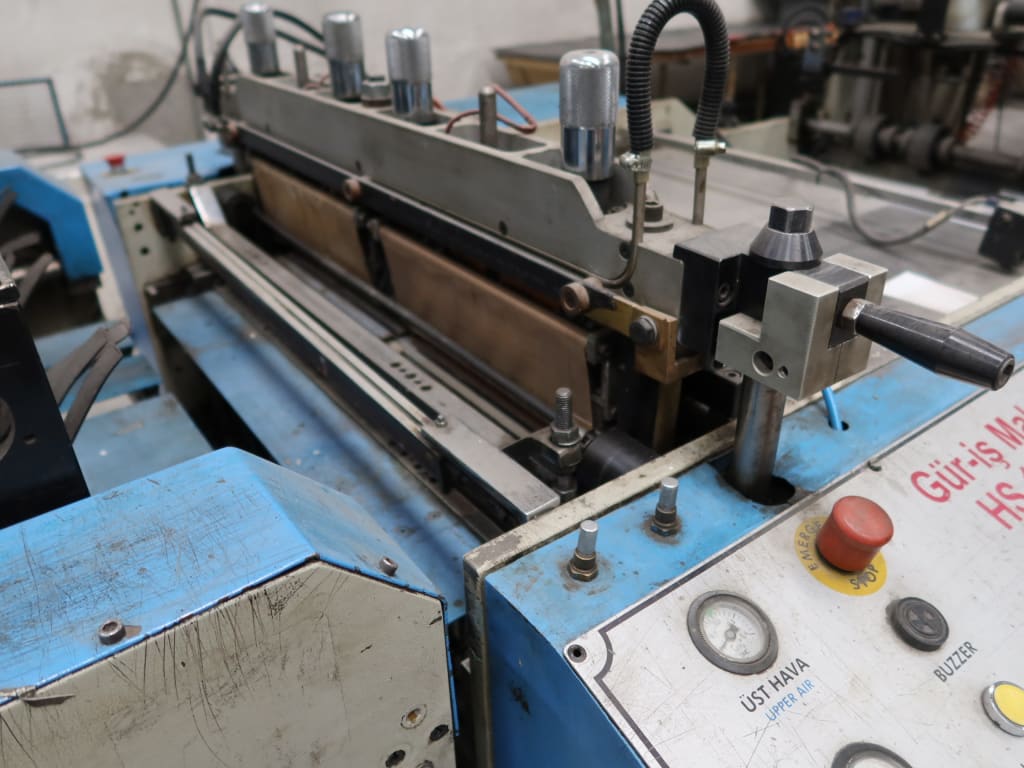

GÜR-İŞ TY 850 Side-Weld Bag-Making Machine (2012)

Side-Sealing Bag Making Line (Folded-Bottom Formation), Operation: Side-Sealing With Folded-Bottom Formation System. Perforation System: 6 mm Diameter Holes. Downstream & Auxiliary Equipment: Output Type: Flat Or Gusseted Bags With Side Weld And Folded Bottom, As Typically Used For Packaging Or Liners. Technical Data (Approx.): Working Width: Max 800 mm, Film Thickness: 20 – 75 µm, Film Type: LDPE / HDPE / LLDPE, Installed Power: 9 kW, Machine Weight: ≈ 2.800 kg. Overall Dimensions: L 6.500 × W 2.500 × H 1.800 mm. Power Supply: 380 V / 50 Hz / 3 Phase. - LOT 18

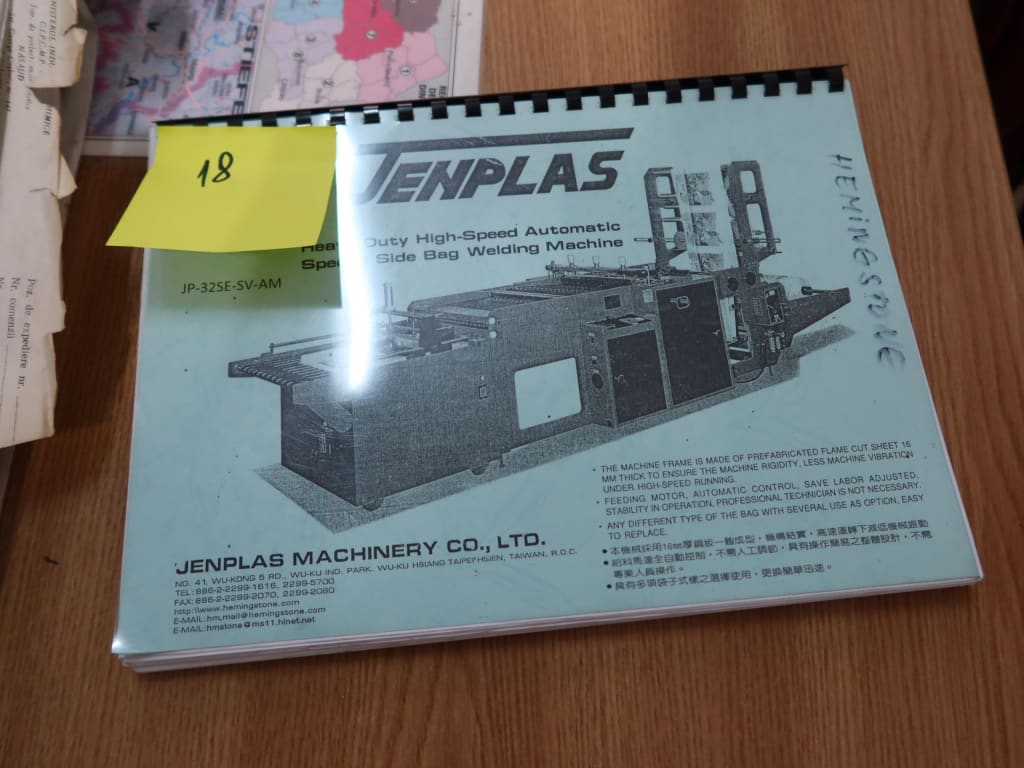

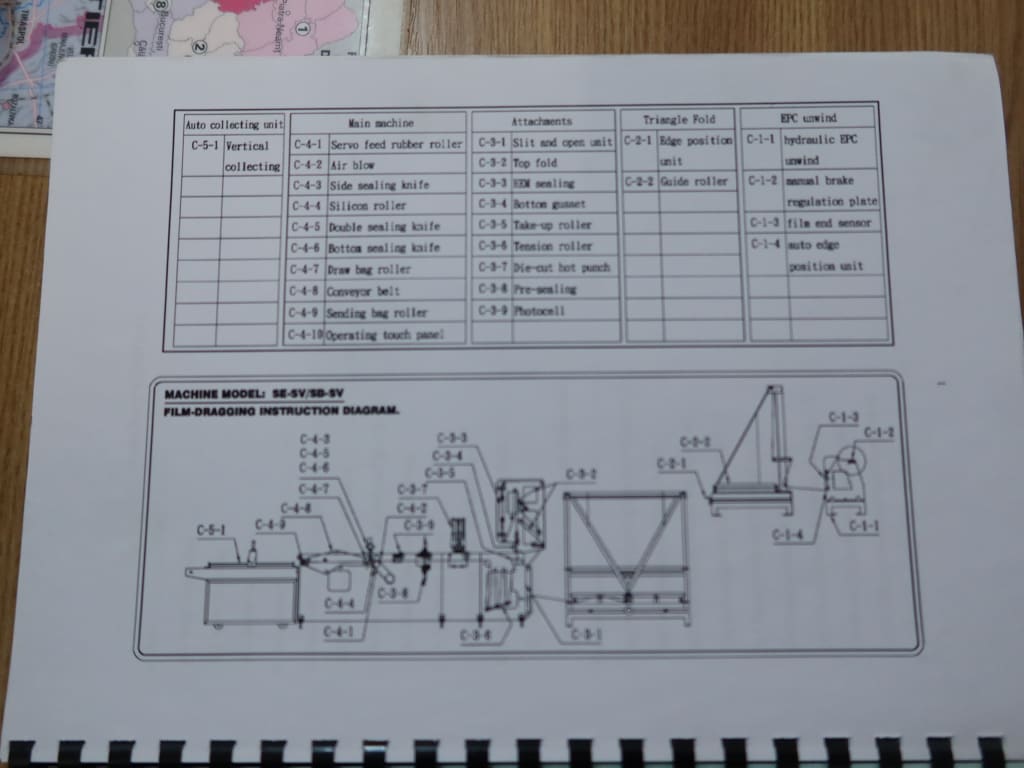

![site]()

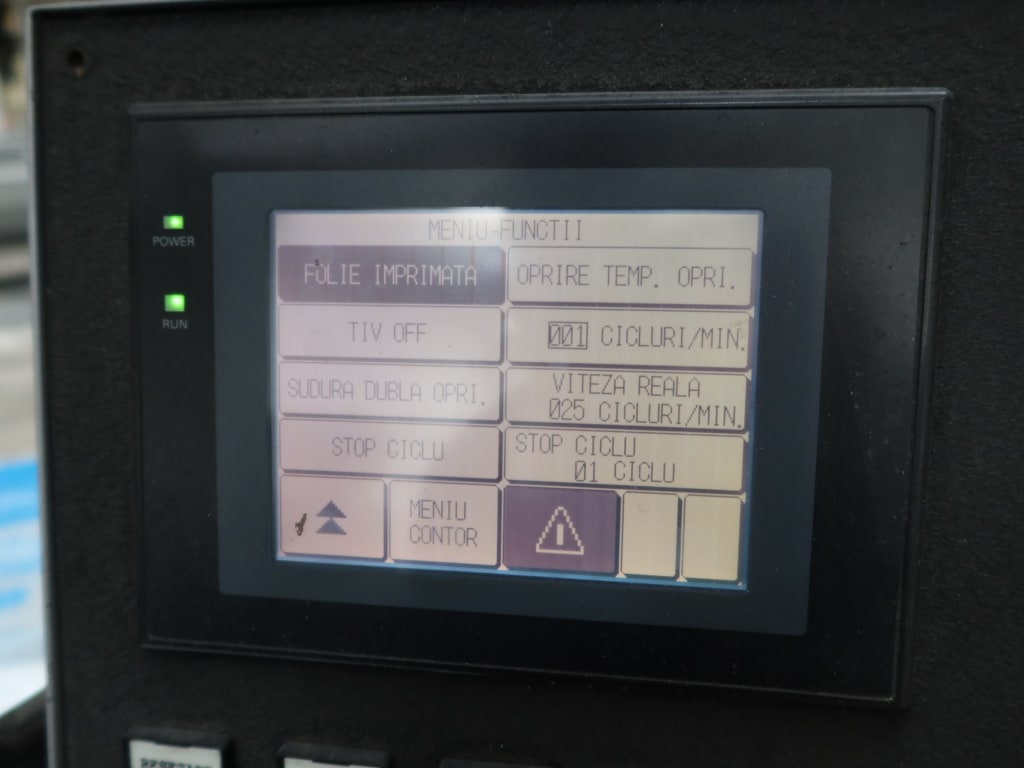

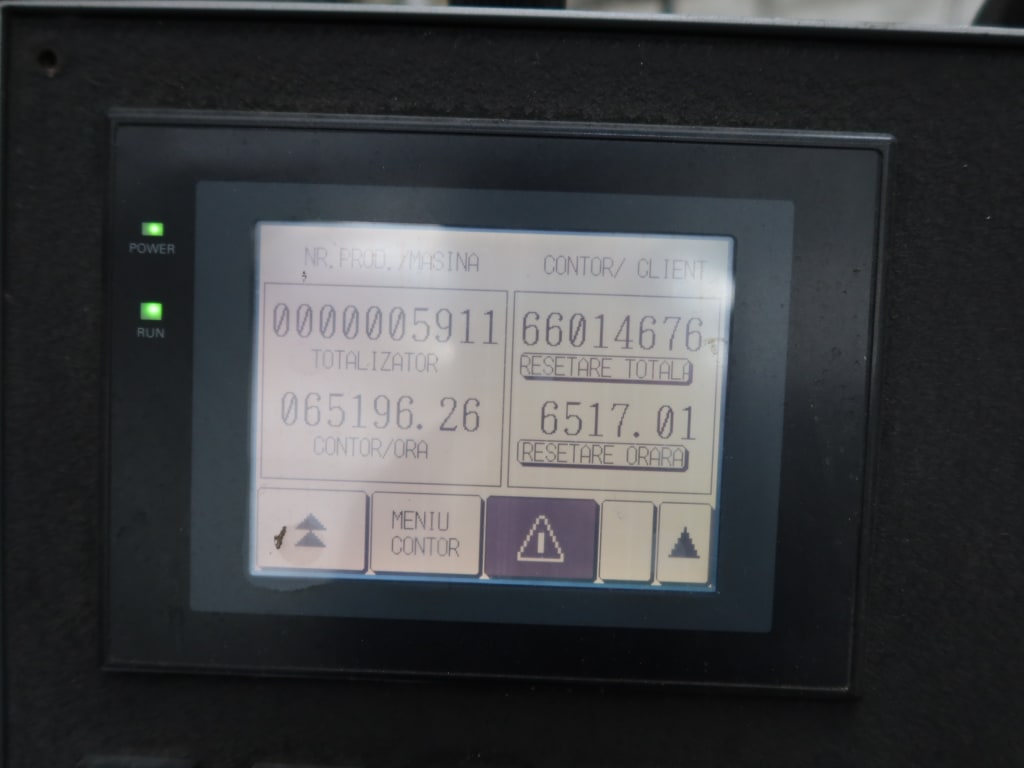

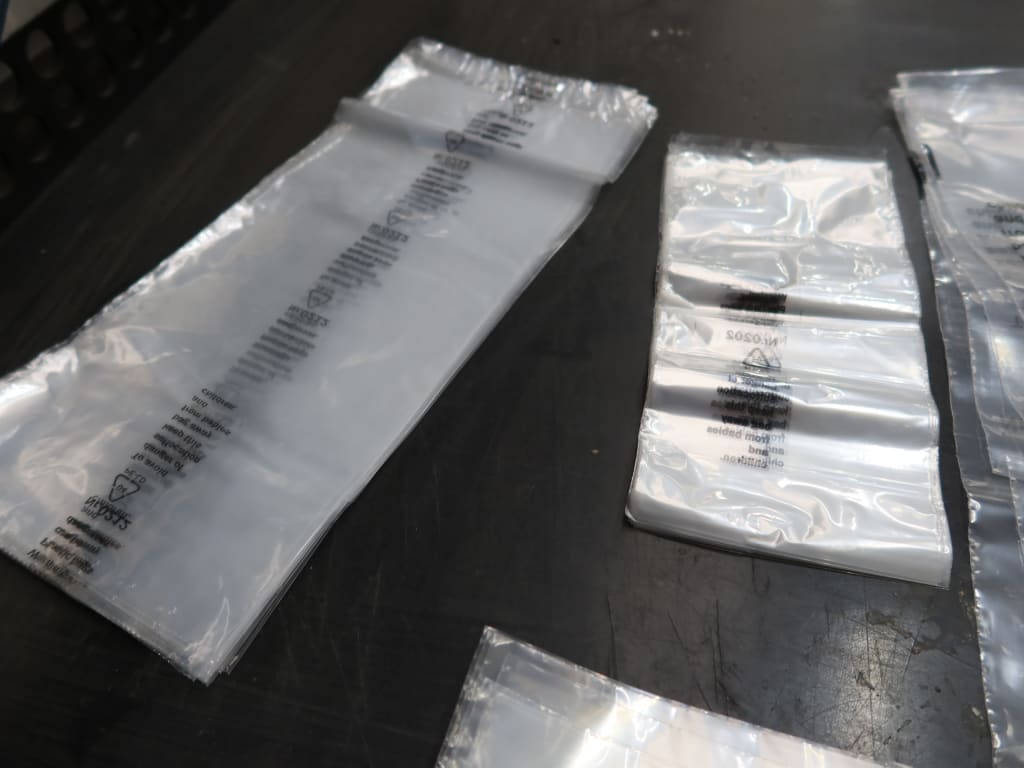

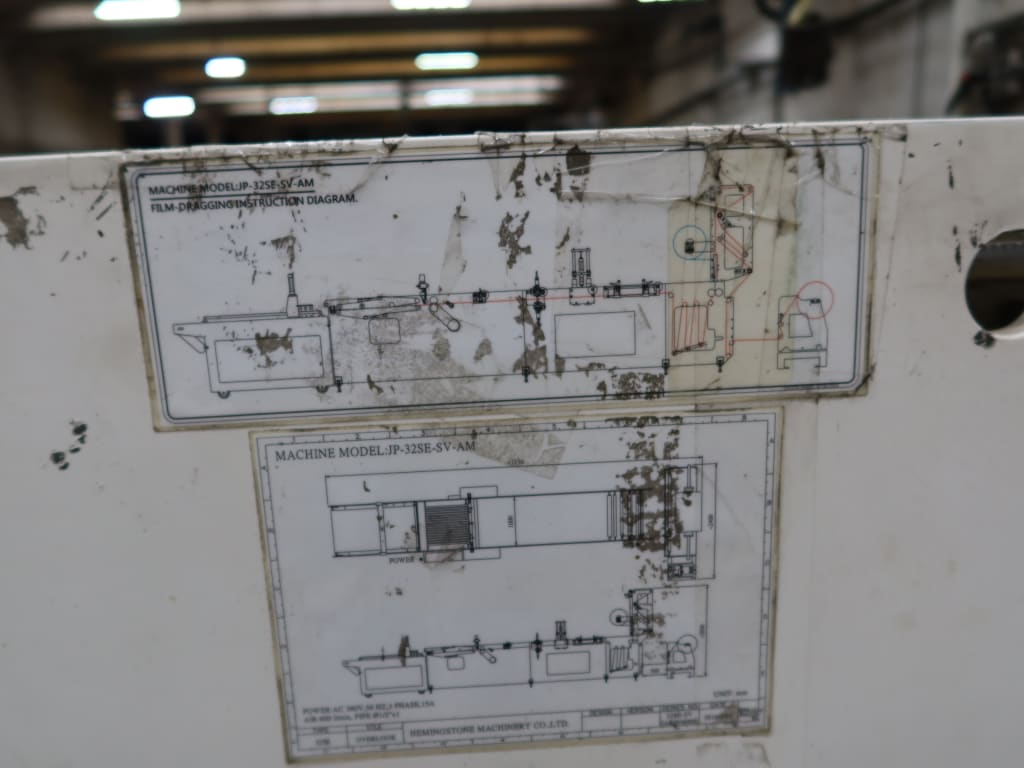

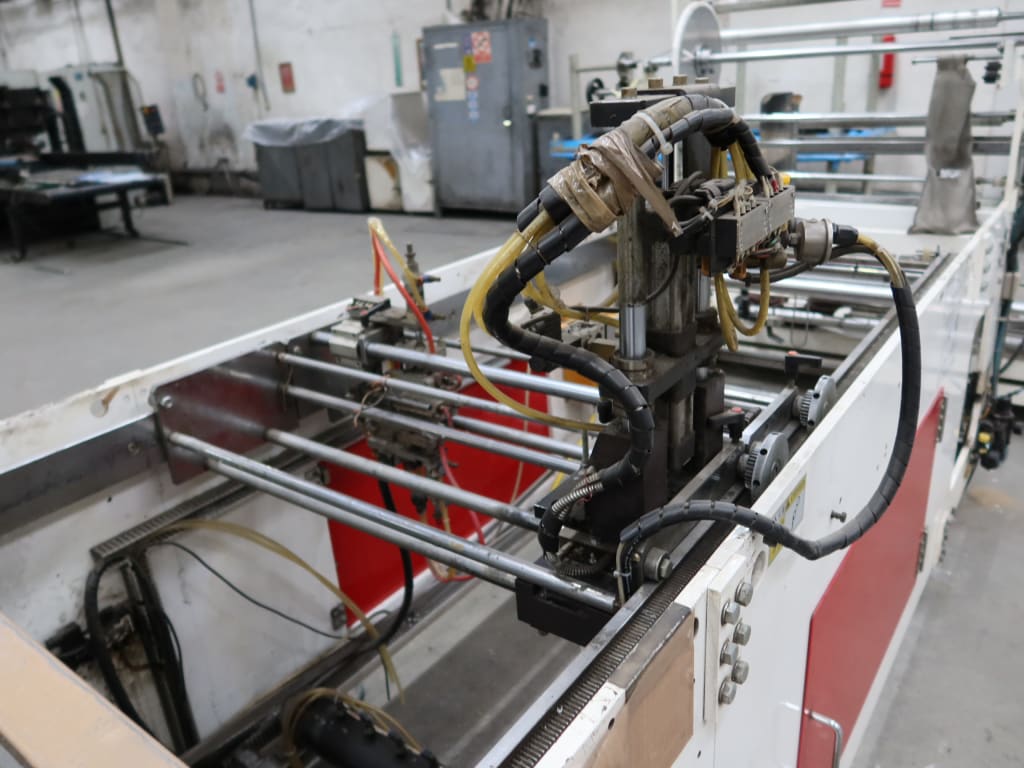

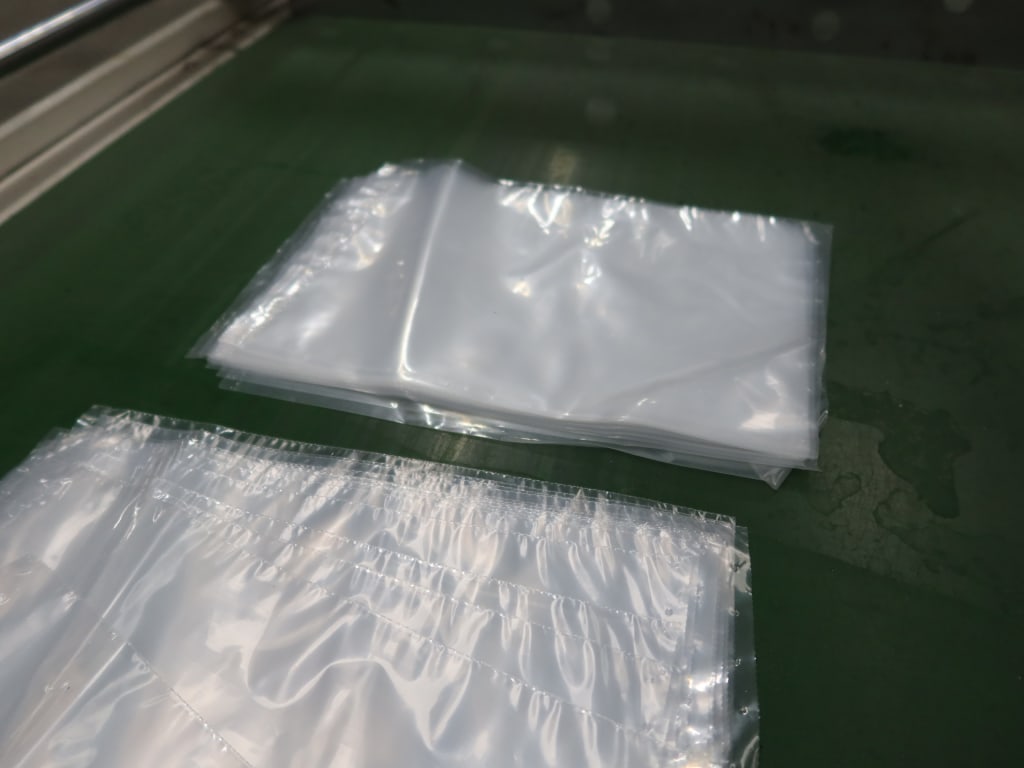

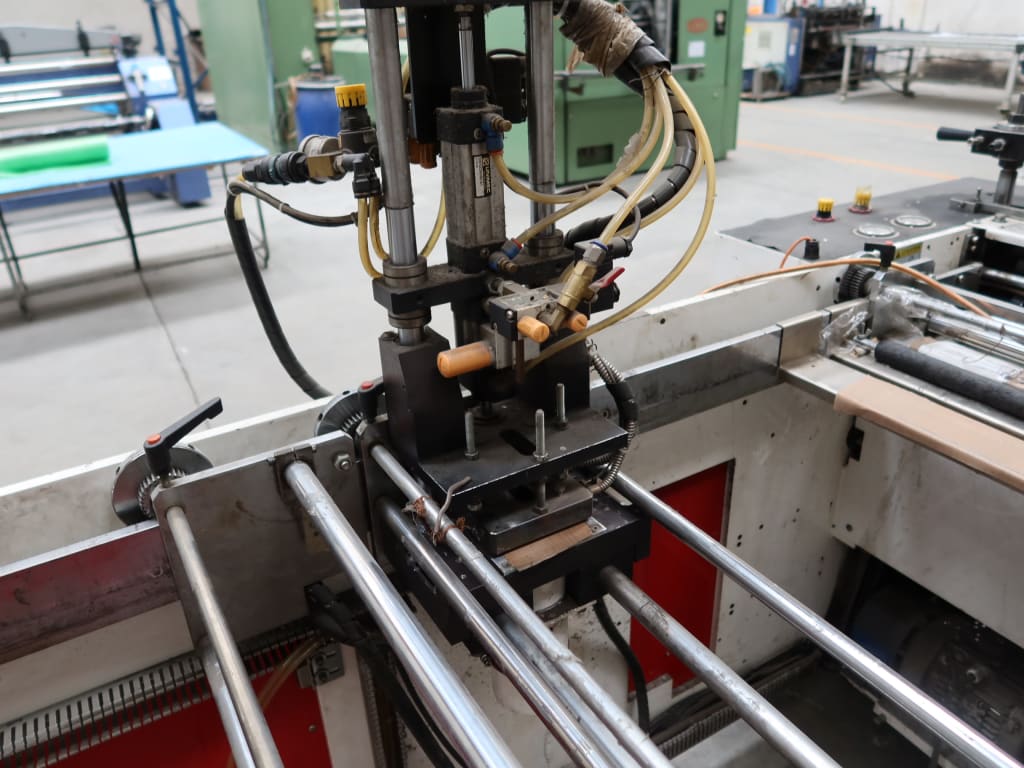

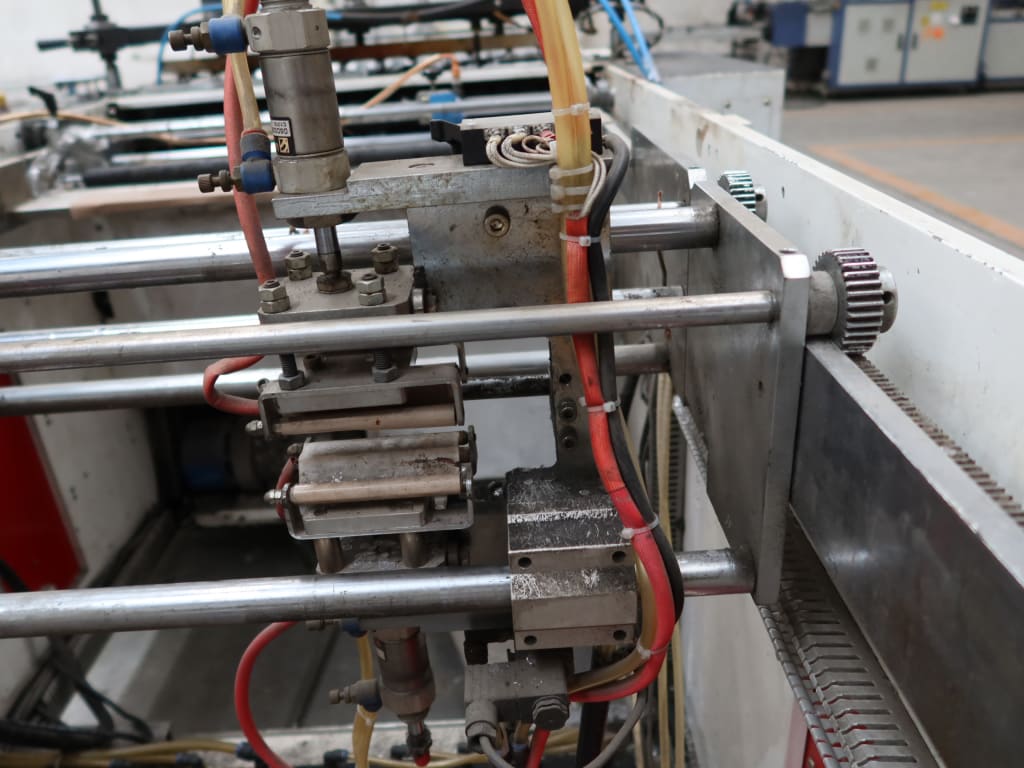

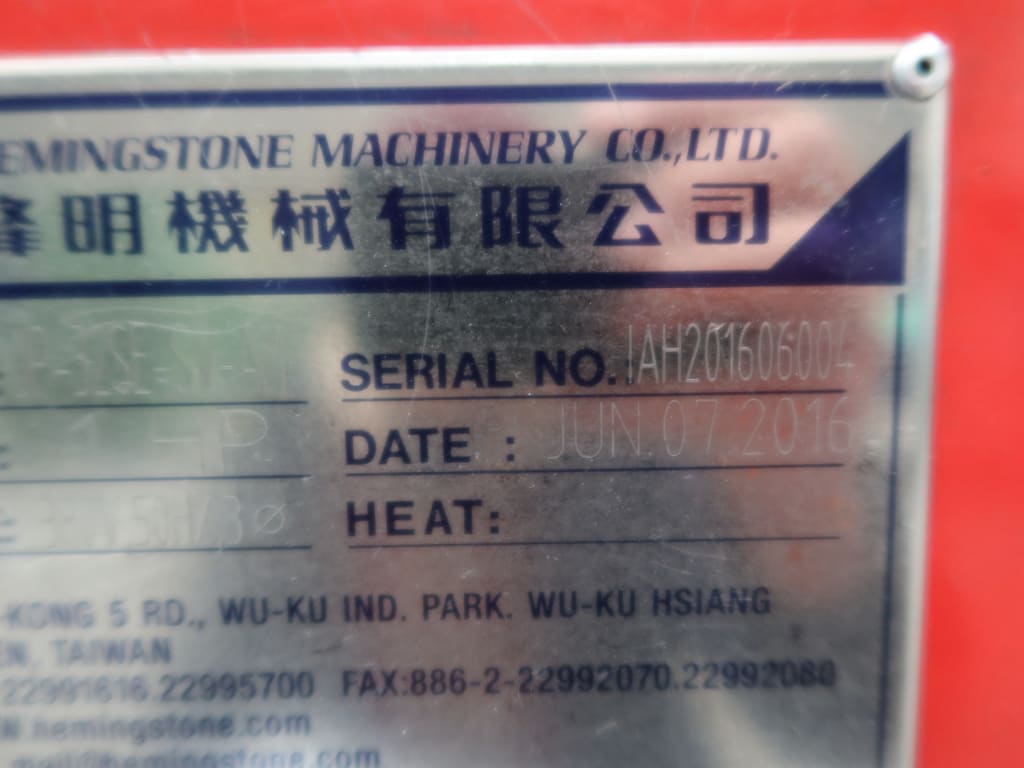

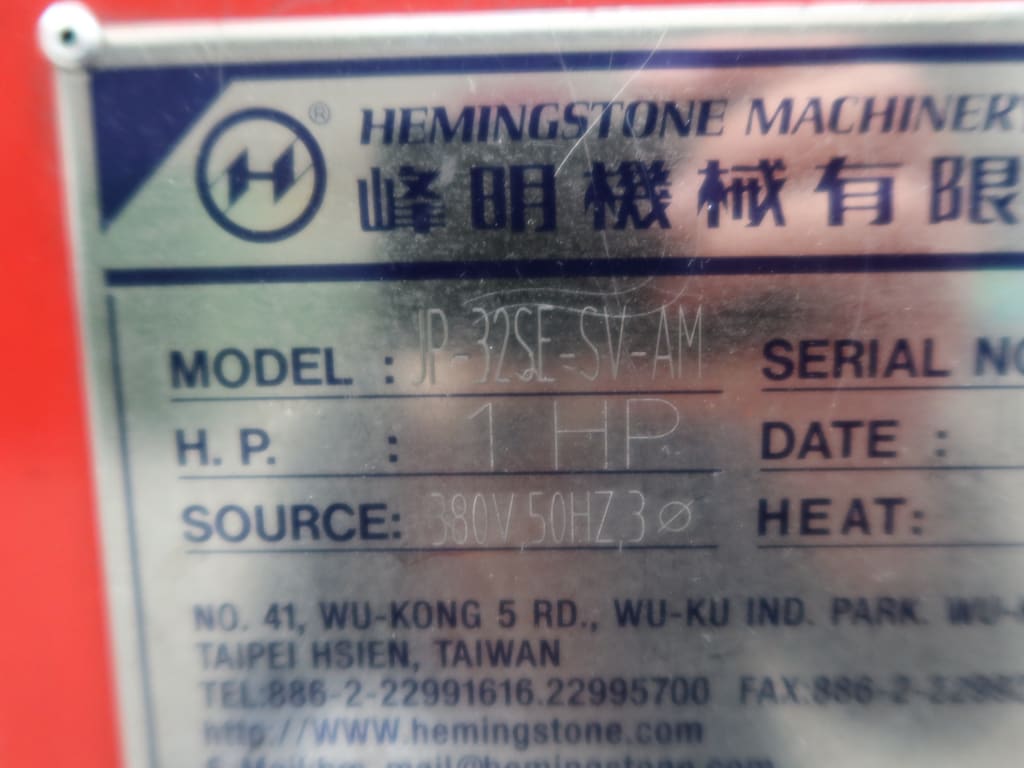

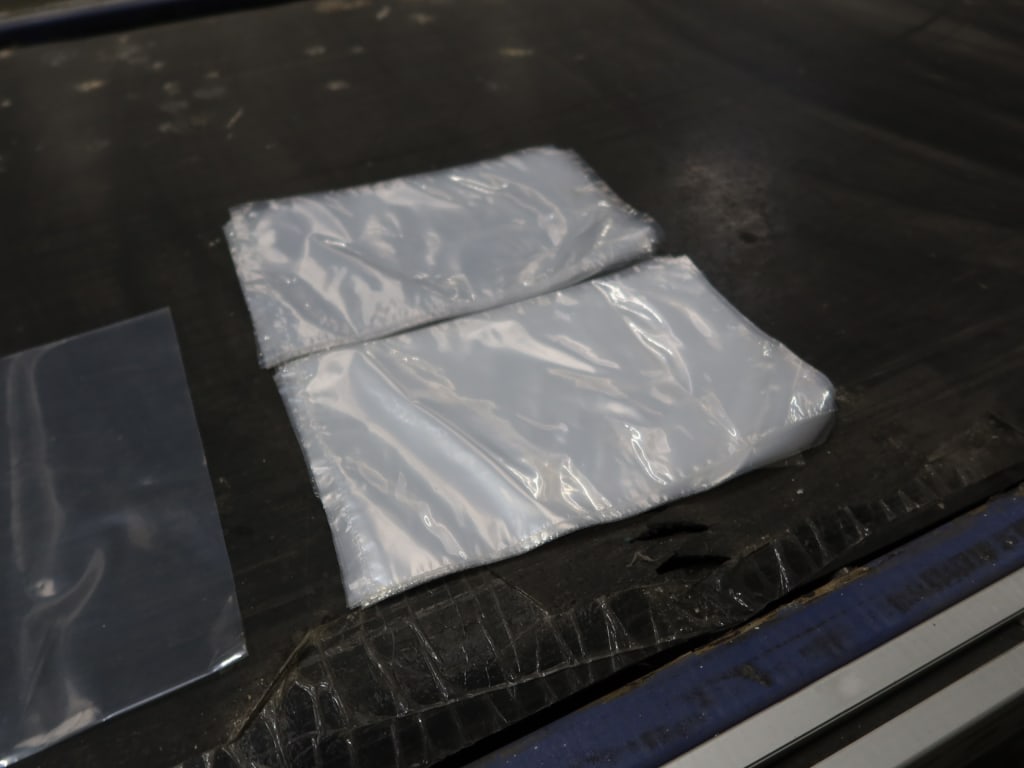

HEMINGSTONE JP-32SE-SV-AM Bottom-Seal & Courier-Bag Making Machine (2016)

Automatic Bag Making Line (Perforation And Seal-Strip Application), Functions: Bottom Sealing, Film Perforation, Adhesive-Tape (Seal-Strip) Application Unit. Perforation System: 6 mm Holes. Downstream & Auxiliary Equipment: Control System: Touchscreen Delta HMI, Servo Feed With Bag Length And Speed Control, Unwinder: With Tension And Brake Control, Conveyor Output Table: With Automatic Stacking. Technical Data (Approx.): Working Width: Max. 800 mm, Film Thickness: 20 – 75 µm, Film Type: LDPE / LLDPE / HDPE, Bag Length: 100 – 400 mm, Bag Width: 100 – 600 mm, Installed Power: ~9 kW. Overall Dimensions: L 7.000 × W 2.500 × H 2.200 mm. Power Supply: 380 V / 50 Hz / 3 Phase. - LOT 19

![site]()

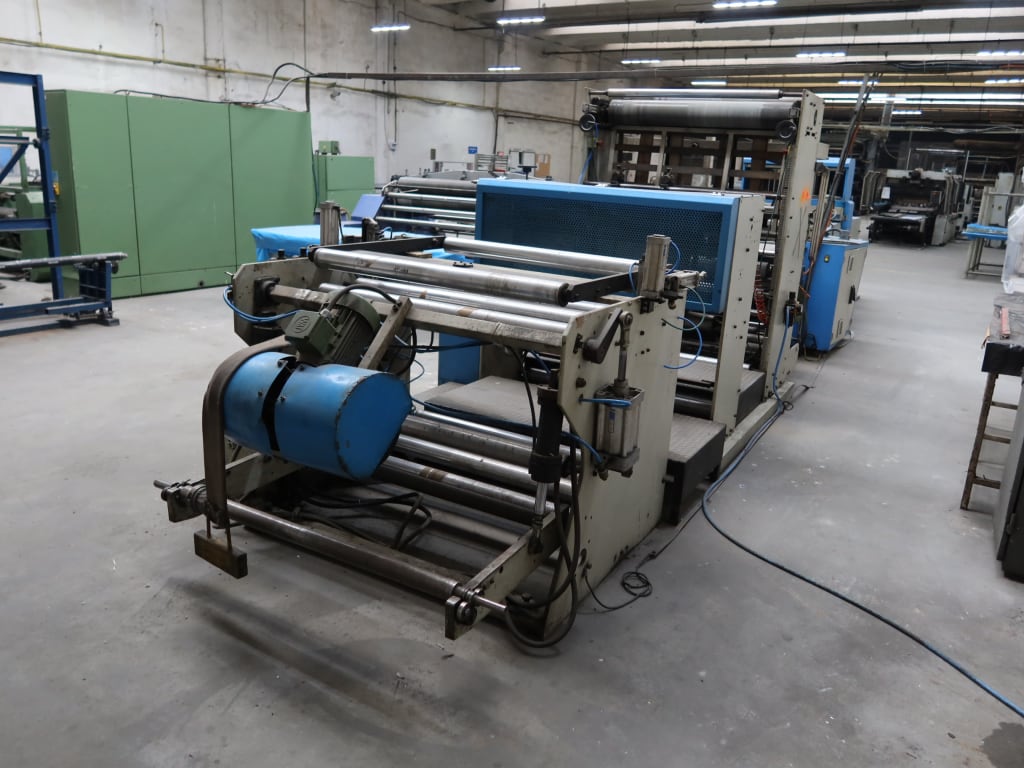

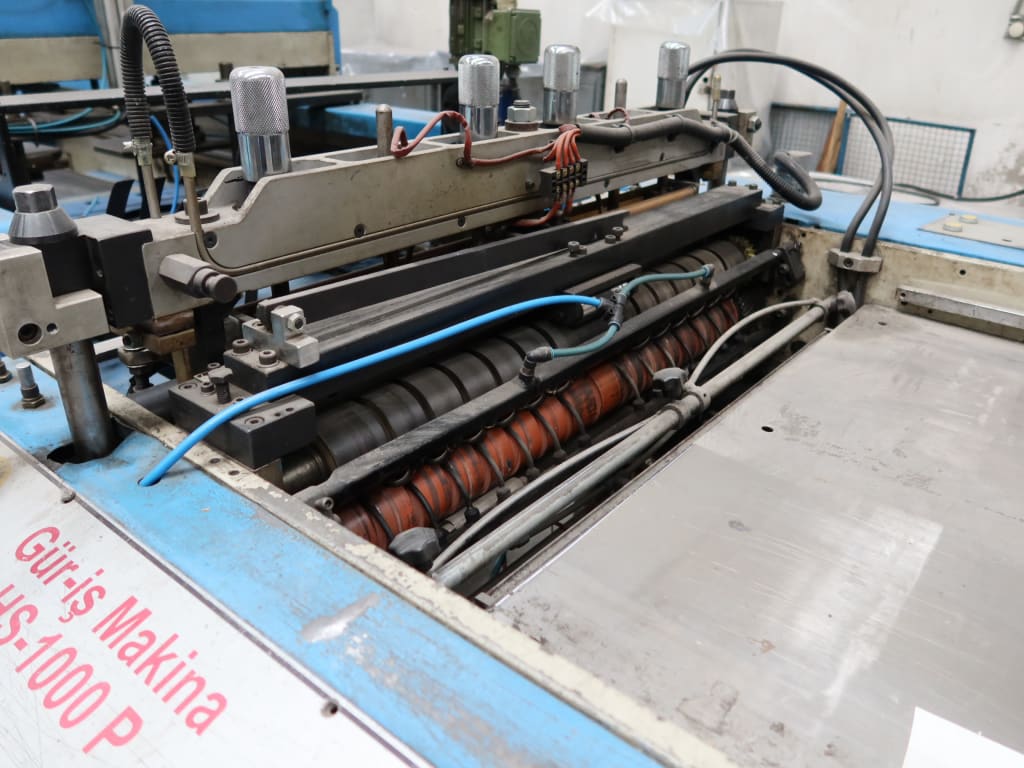

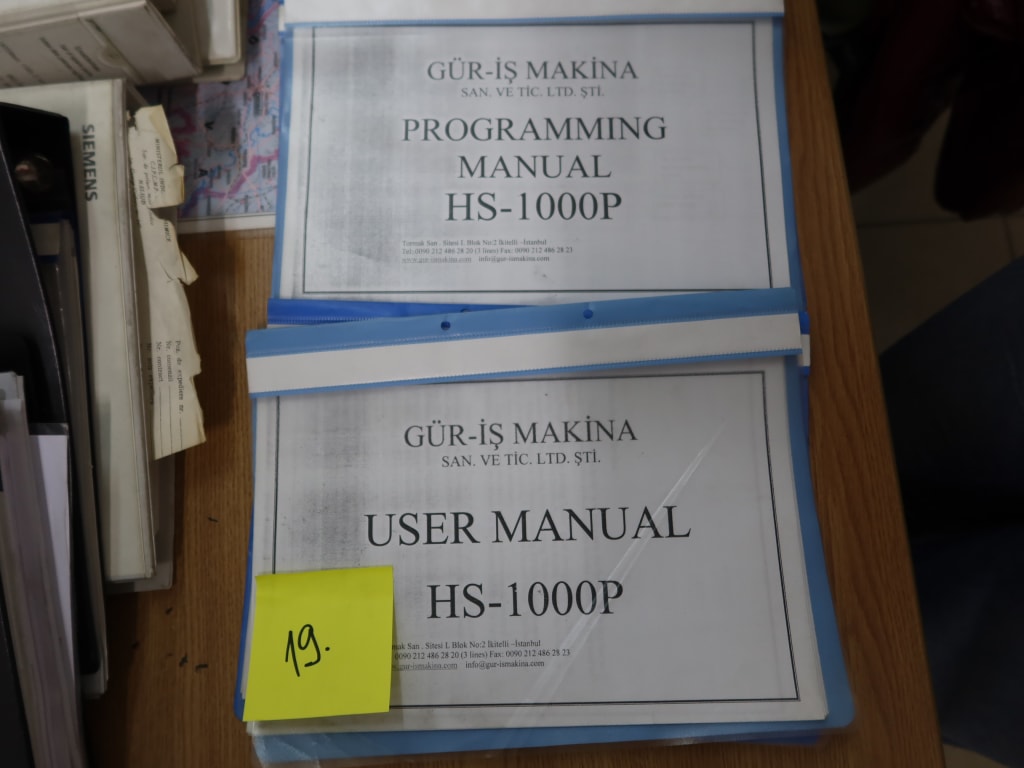

GÜR-İŞ MAKINA HS-1000P + DD700 T-Shirt Bag Making Line (2006)

T-Shirt Bag Making Line (Two Tracks, Hydraulic Punching), Comprising Of The Following Main Components, Film Unwinder: With Pneumatic Shaft. Hot Knife Longitudinal Cutter: Splitting 1.100 mm Film Into 2 Tracks. Cutting And Bottom Sealing Station: With Upper/Lower Heat Jaws. T-Shirt Handle Punching Unit: With Hydraulic Press. Downstream & Auxiliary Equipment: Side Gusset Folding Unit, Film Guiding System, Stacking Conveyor: With Automatic Counting (Currently Set To 25 pcs), Control Panels: With Independent Temperature Controllers (Siemens / Fuji), Antistatic System And Pneumatic Film Tension Control. Technical Data (Approx.): Material: HDPE / LDPE / LLDPE, Film Width (Unwind): Max. 1.100 mm (Divided Into 2 Tracks), Current Working Width: Max. 500 mm (Effective 320 mm On Single Track), Bag Width: 250 – 320 mm, Bag Length: 400 – 650 mm, Film Thickness: 10 – 70 µm, Installed Power: 18 kW. Overall Dimensions: L 10.000 × W 1.700 × H 2.500 mm. Power Supply: 380 V / 50 Hz / 3 Phase - LOT 20

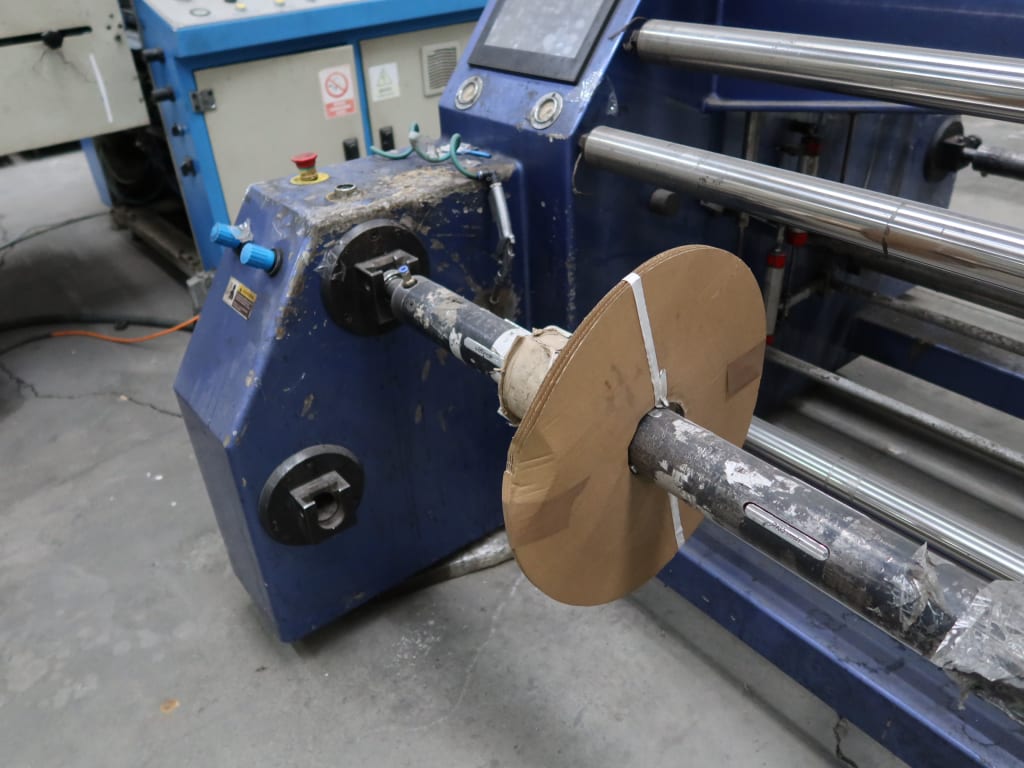

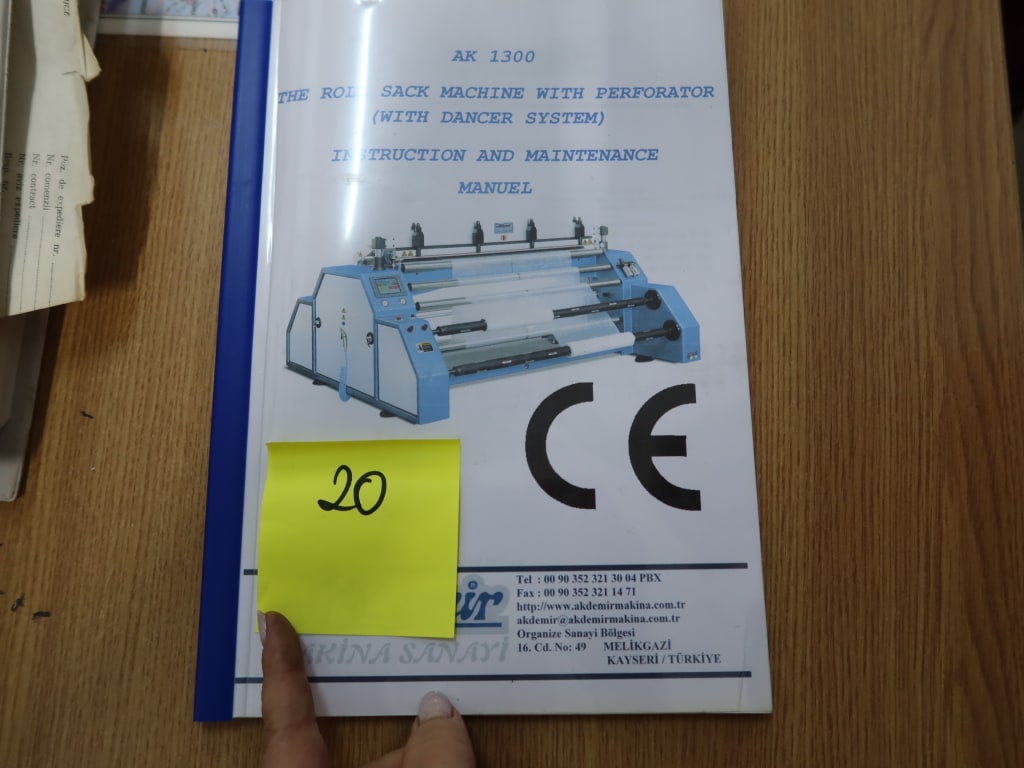

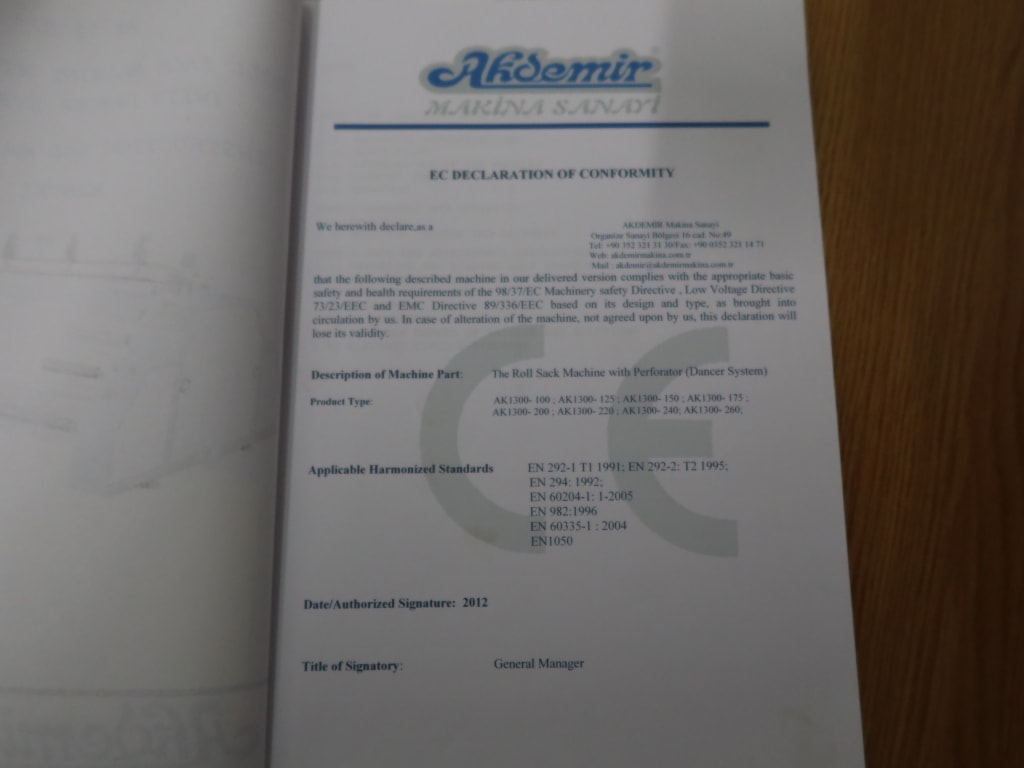

![site]()

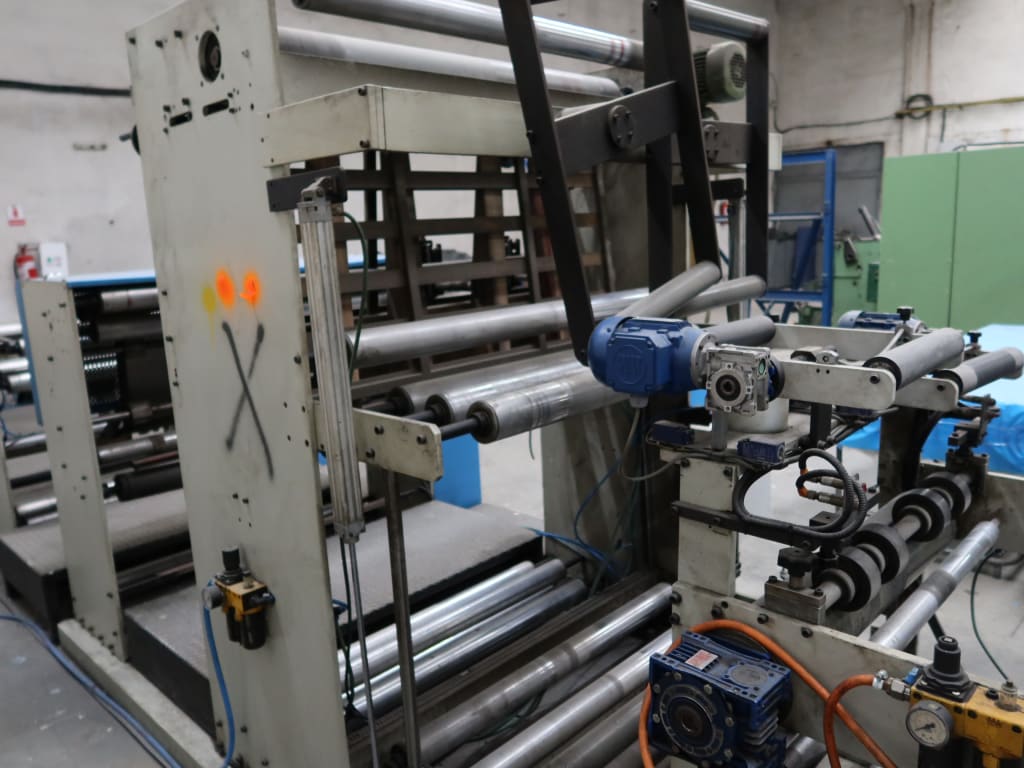

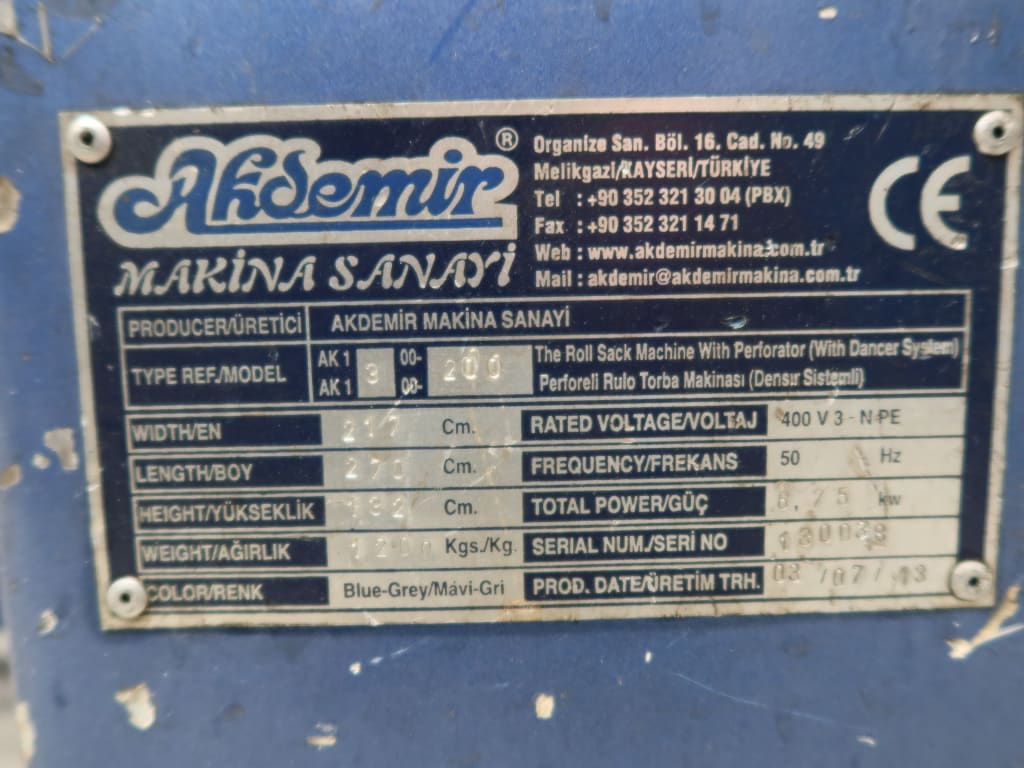

AKDEMİR AK1-200 Roll Rewinder with Perforation (for Heavy-Duty Film Rolls) (2013)

Heavy-Duty Film Rewinding Unit (Integrated Perforation System), Main Function: Heavy-Duty Film Rewinding Unit For Thick Polyethylene Sheets Or Tubular Film. Perforation System: Integrated Perforation System For Roll-To-Roll Separation. Downstream & Auxiliary Equipment: Tension Control: Dancer System For Automatic Tension Regulation, Core Mounting: Pneumatic Shafts For Core Mounting, Control Panel: Touch-Screen Operator Control Panel, Operation Modes: Manual And Automatic Mode Operation, Features: Robust Frame Suitable For High-Thickness Film, Adjustable Speed And Perforation Repeat Length. Technical Data (Approx.): Max. Working Width: 2.000 mm, Max. Distance Between Perforations: 6.000 mm, Film Thickness Range: 40 – 600 µm, Core Diameter: 76 mm, Max. Film Roll Diameter: 700 mm (Approx.), Material Types: LDPE / LLDPE / HDPE / Shrink Film, Installed Power: 6.75 kW, Weight: 1.200 kg. Overall Dimensions: L 2.170 × W 2.700 × H 1.320 mm. Power Supply: 400 V / 50 Hz / 3 Phase. - LOT 21

![site]()

LEMO ROLLOMAT 850 Machinenbau GmbH Bag-on-Roll Line

Film Converting/Rewinding Line (2 Lanes, Pneumatic Unwinder), Comprising Of The Following Main Components, Film Unwinder: With Pneumatic Shaft. Folding And Gusseting Unit. Sealing And Perforation Section. Downstream & Auxiliary Equipment: Automatic Rewinding System: For Roll Formation, Controls: Manual Adjustment Controls And Mechanical Repeat System, Status: One Lane Disconnected, Mechanical Parts For Second Lane Still Present. Technical Data (Approx.): Max. Film Width (Input): 1.200 mm, Max. Working Width (Output): 400 mm Per Roll, Number Of Lanes: 2 (Currently 1 Functional), Film Thickness: 10 – 80 µm, Roll Core Diameter: 40 / 50 / 76 mm, Film Type: LDPE, LLDPE, HDPE, Output: Adjustable Depending On Material And Roll Size. Overall Dimensions: L 7.500 × W 2.500 × H 1.700 mm. Power Supply: 400 V / 50 Hz / 3 Ph. - LOT 22

![site]()

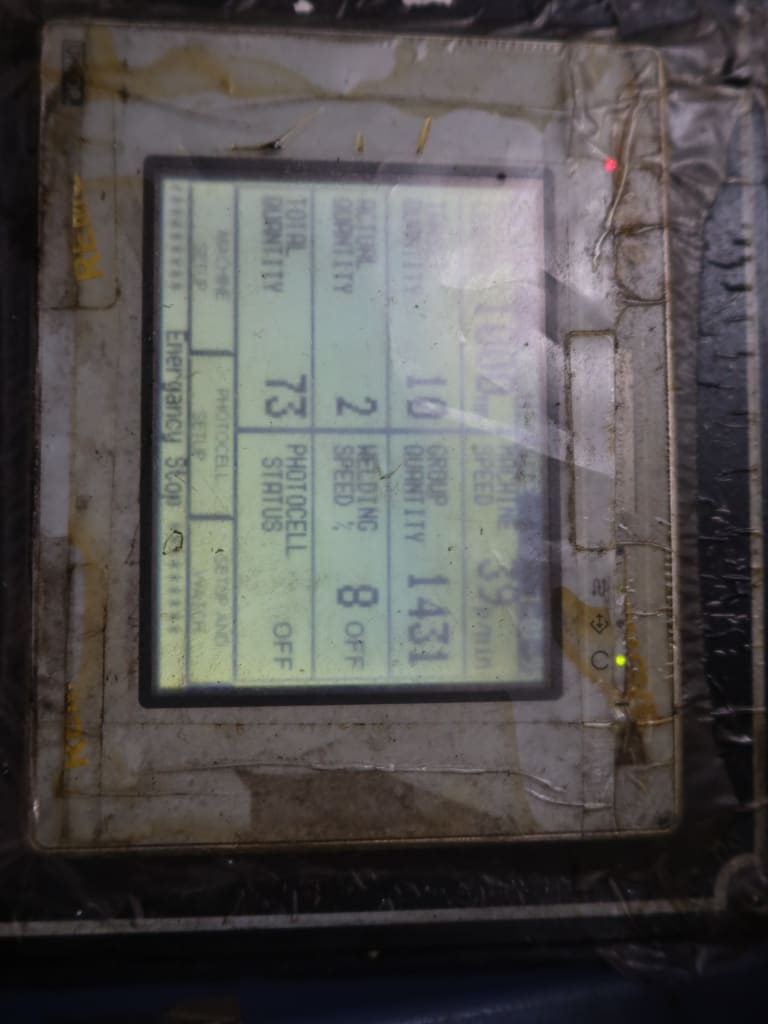

GÜR-İŞ MAKINA BS 1100 WL Bottom-Sealing Bag Machine (2000)

Automatic Bag Making Line (Bottom Seal, Stacking, Perforation), Comprising Of The Following Main Components, Automatic Unwinder: With Pneumatic Shaft. Bottom Sealing And Cutting Unit: Hot Knife. Perforation And Photo-Cell Synchronization. Cutting Knives: 2, Working On 3 Lanes. Downstream & Auxiliary Equipment: Stacking Conveyor: With Adjustable Counter, Tension Control: Pneumatic Lifting Arms And Film Dancer System, Control Panel: Basic Control Panel With Mechanical Length Setting. Technical Data (Approx.): Max. Film Width: 1.100 mm, Film Thickness Range: 15 – 100 µm, Bag Length Range: 1.500 – 4.500 mm (Depending On Setup), Film Type: LDPE, HDPE, LLDPE, Installed Power: Approx. 8 – 10 kW. Overall Dimensions: L 6.500 × W 2.500 × H 2.200 mm. Power Supply: 400 V / 50 Hz / 3 Ph. - LOT 23

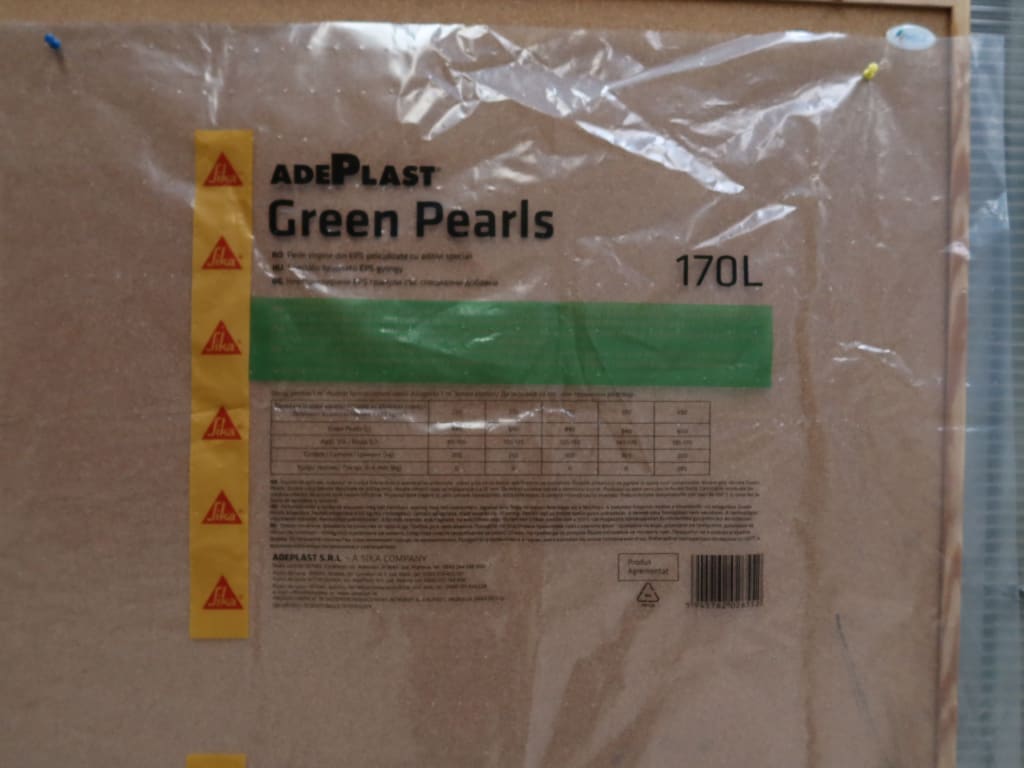

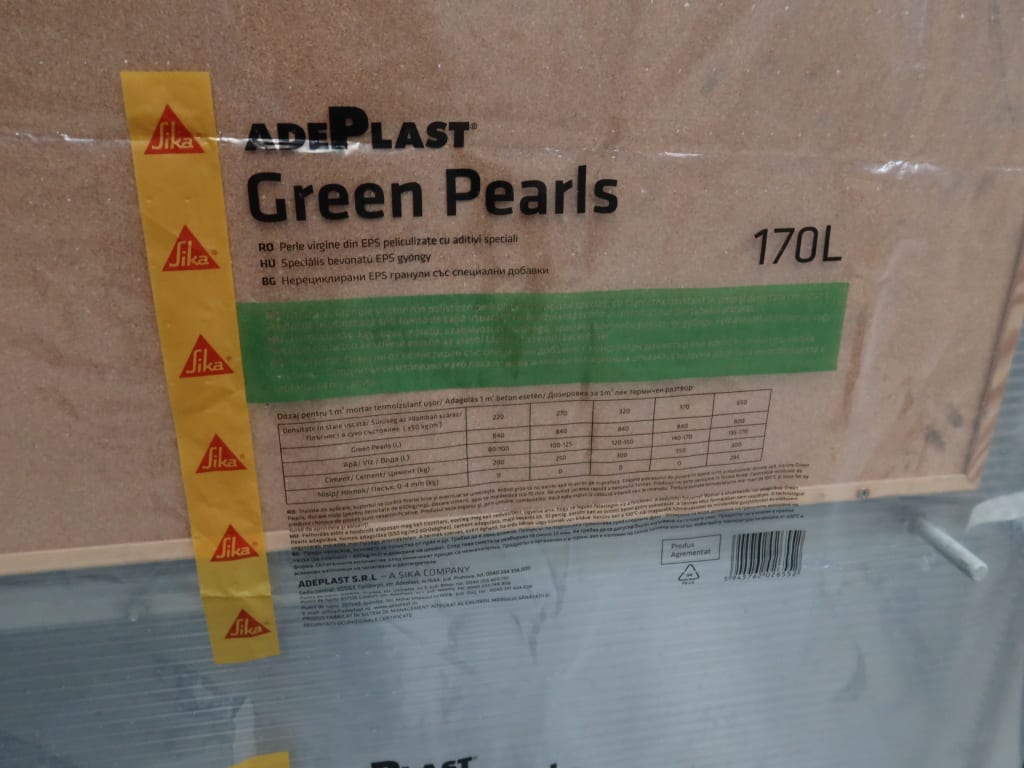

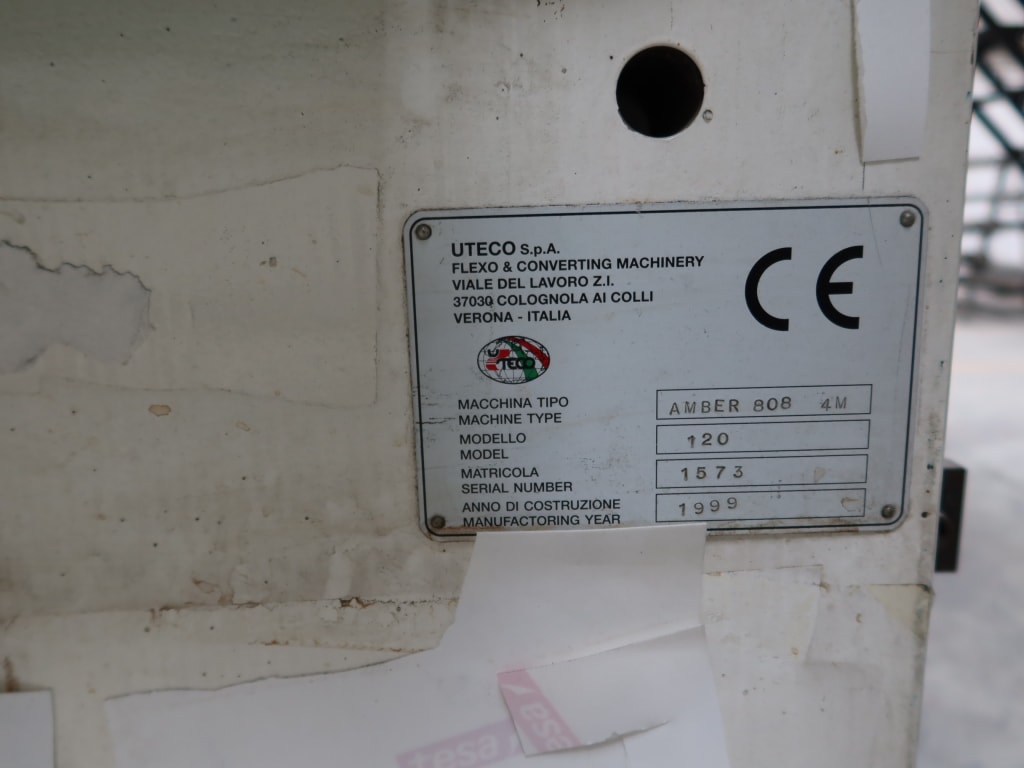

![site]()

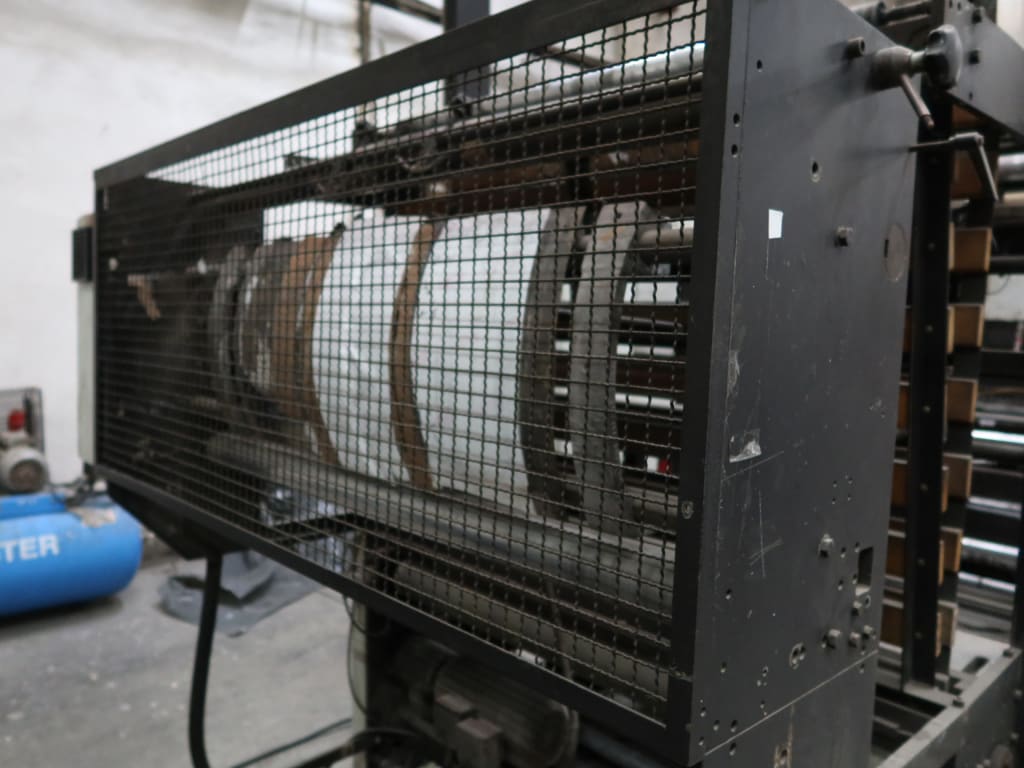

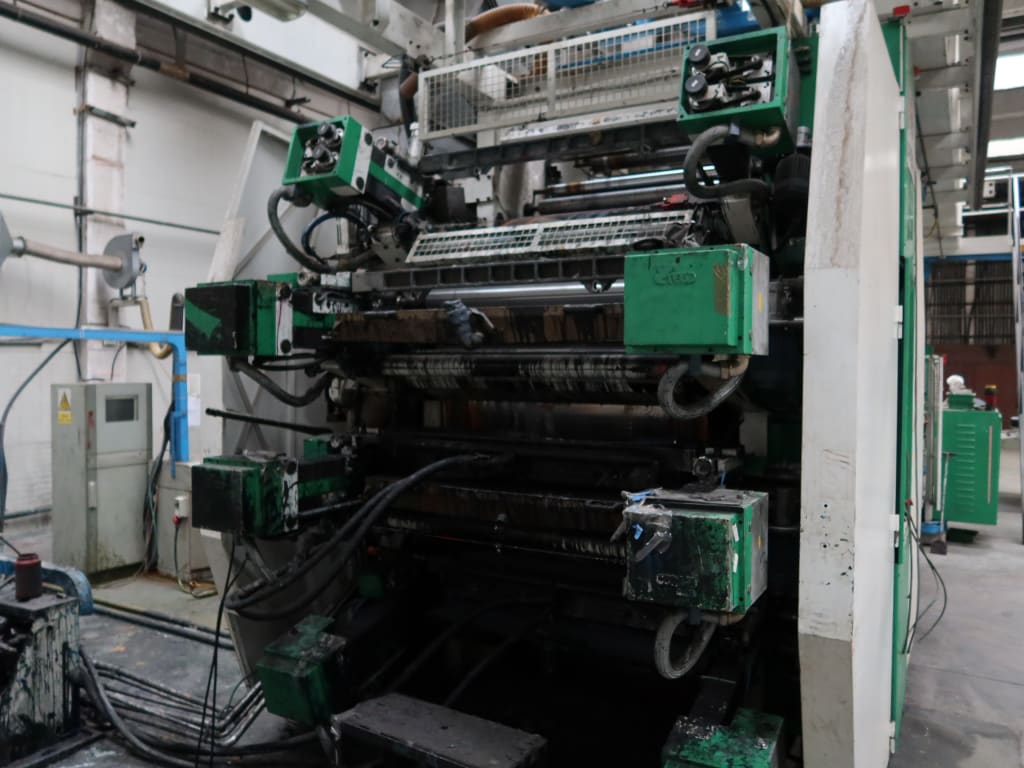

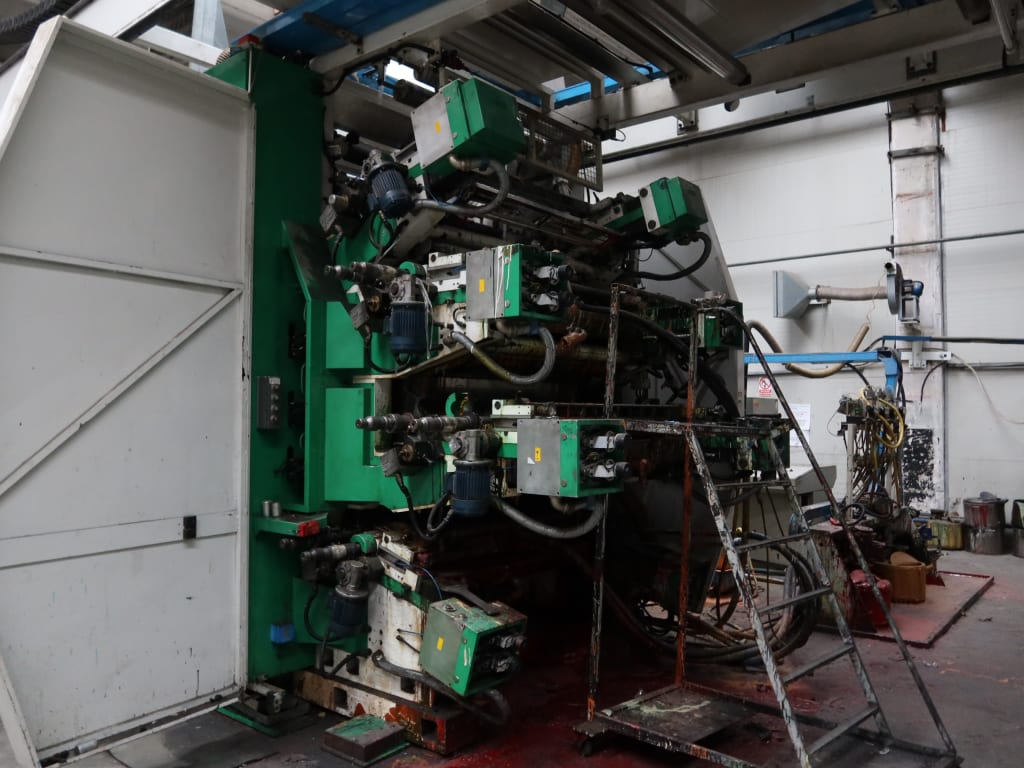

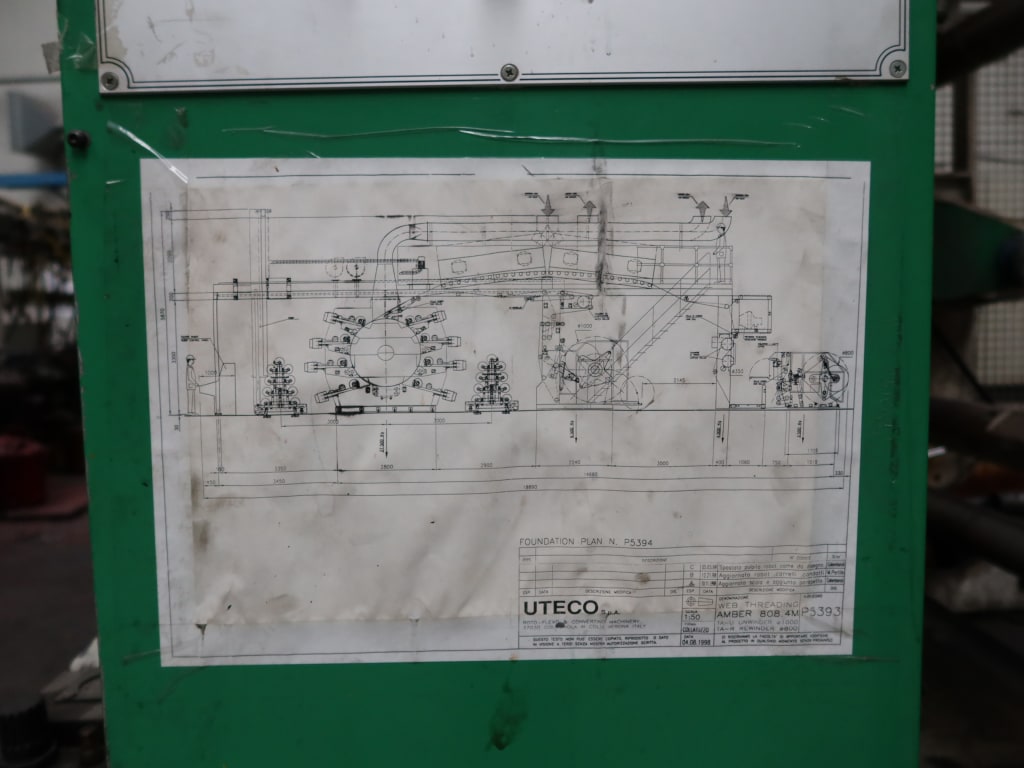

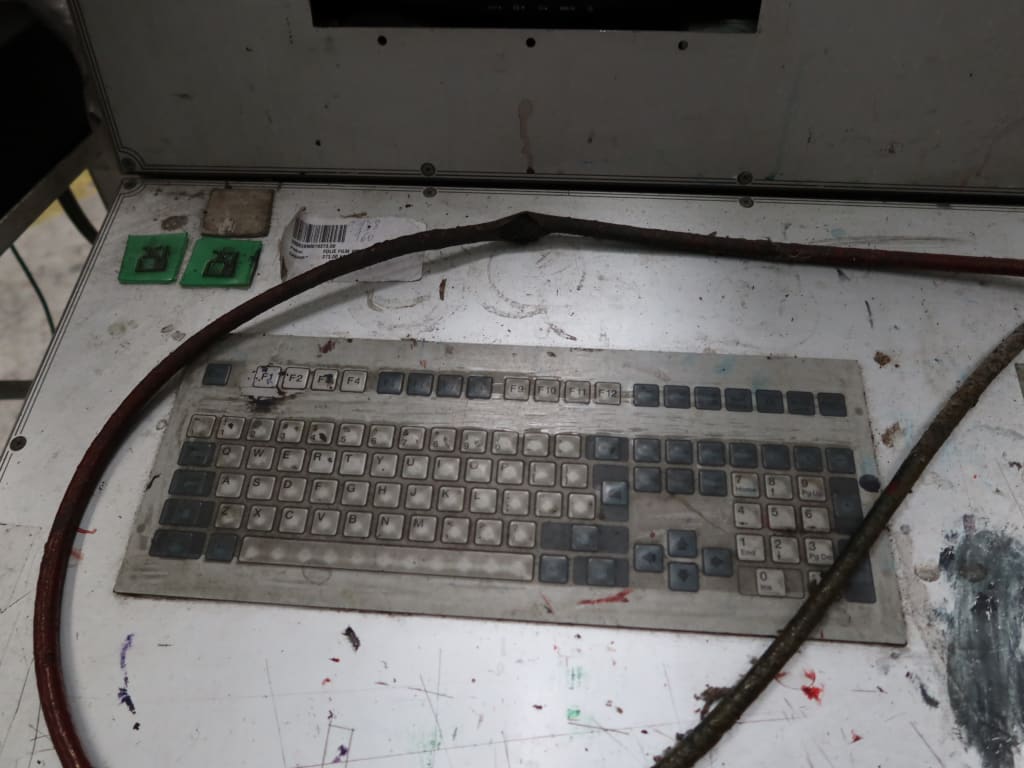

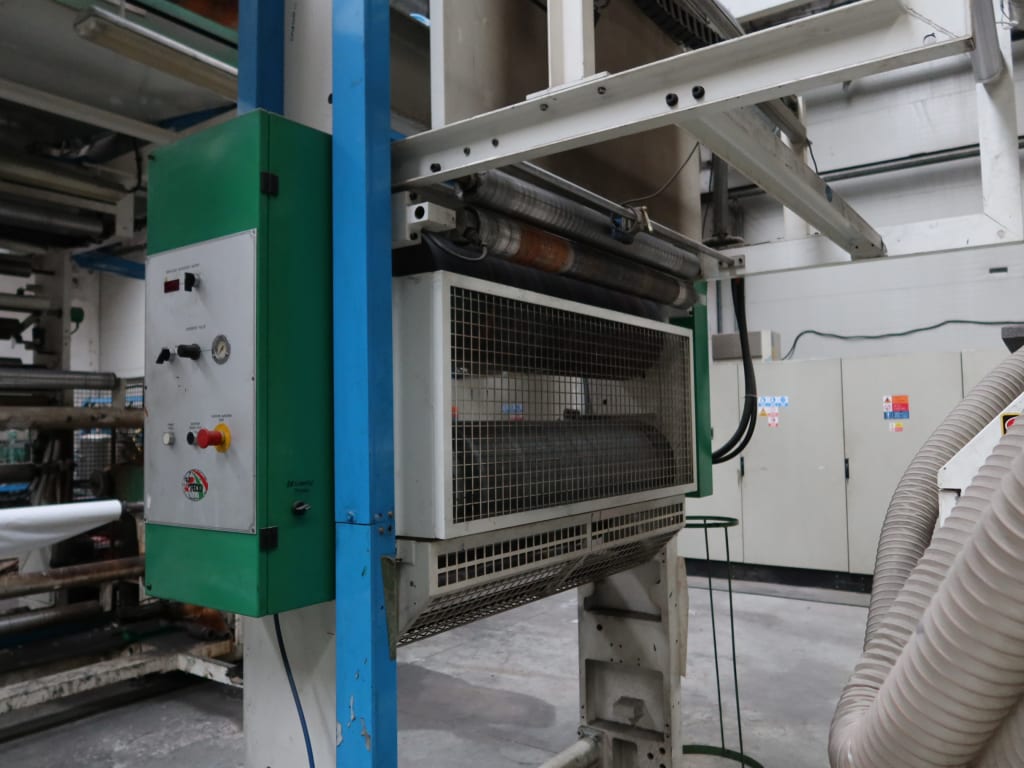

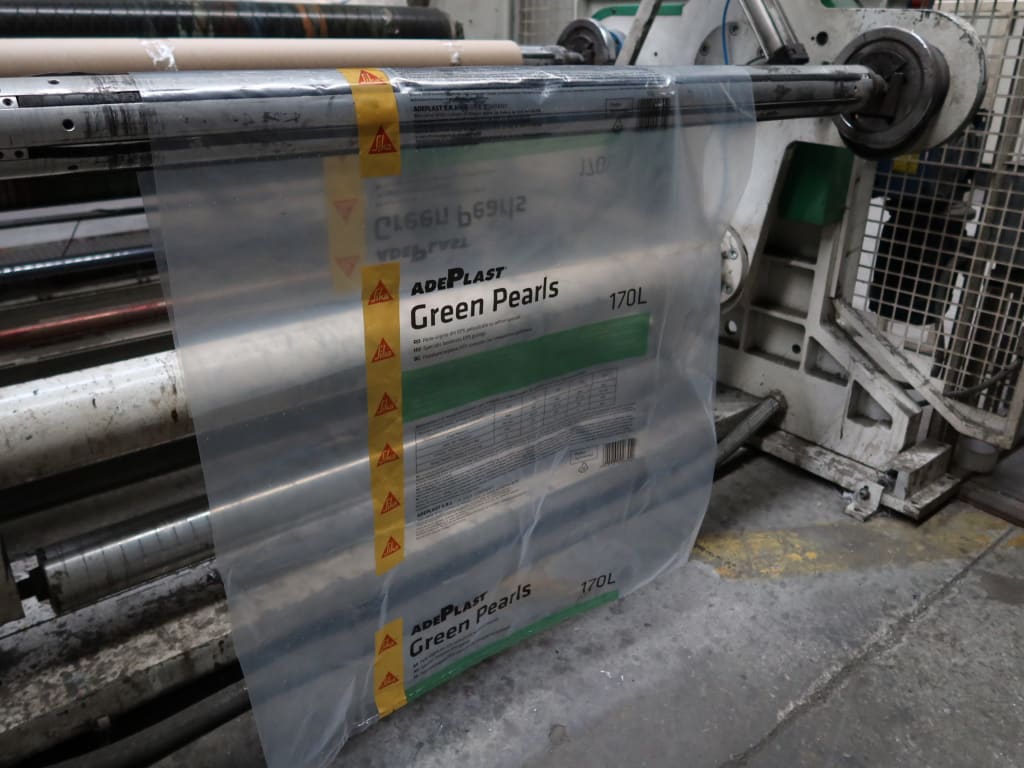

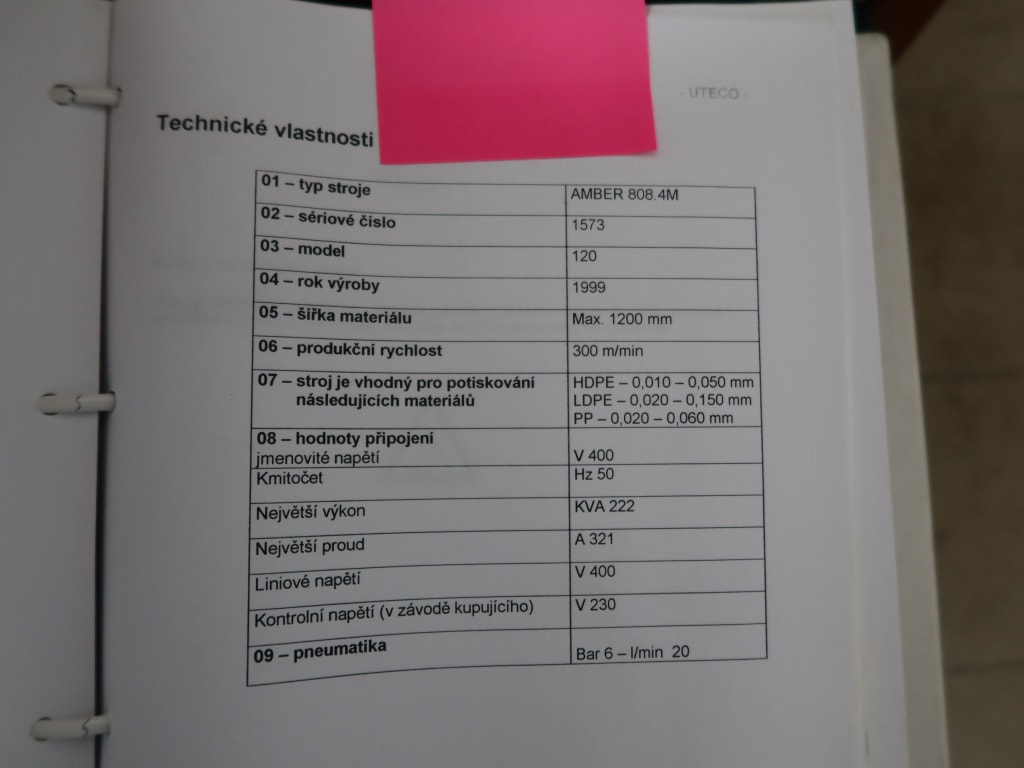

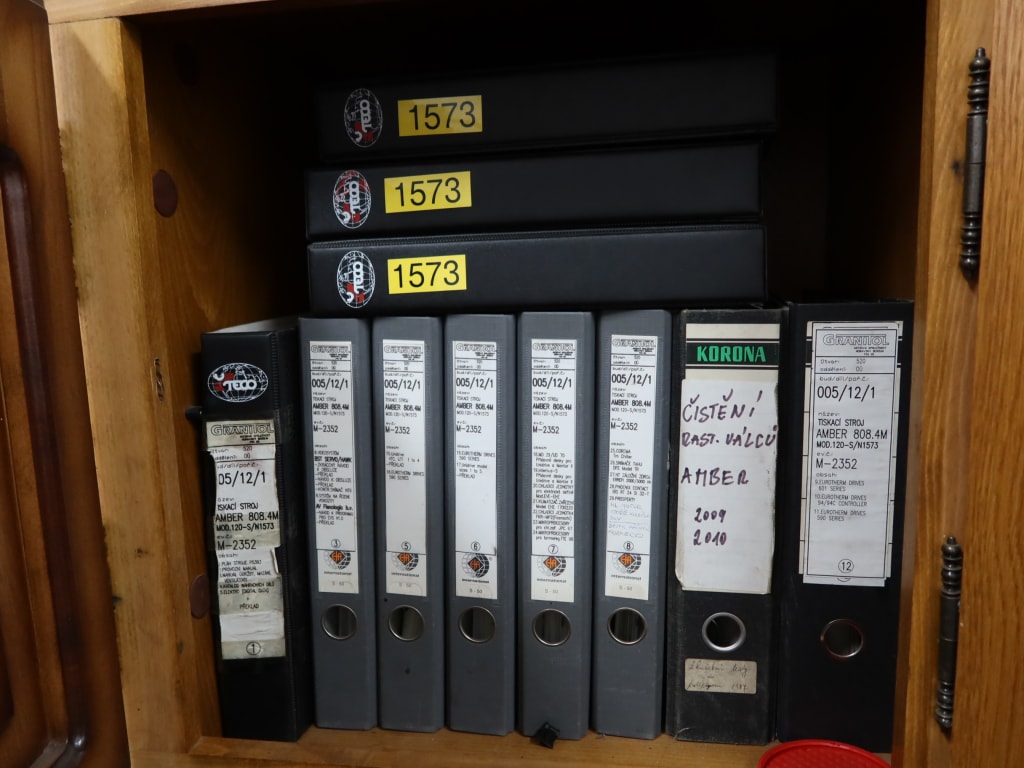

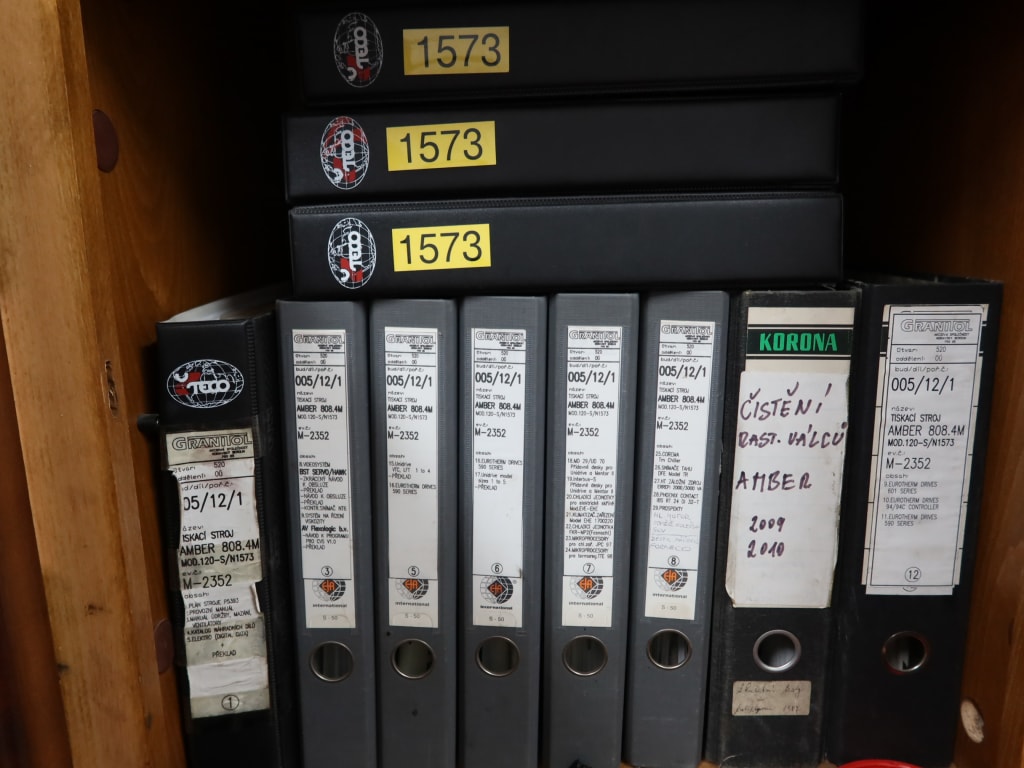

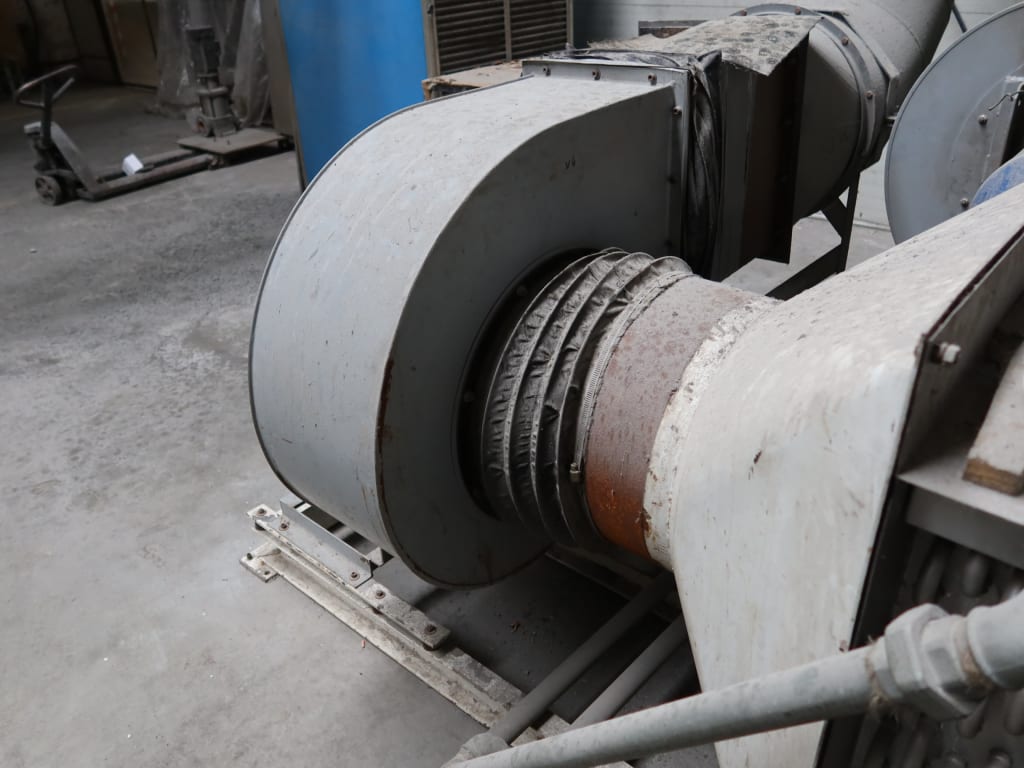

UTECO AMBER 808 4M 8 Colour Flexographic Printing Machine (1999)

8 Colour Central Impression (CI) Printing Line (Solvent-Based, 5 Functional Units), Comprising Of The Following Main Components, Printing Units: 8 Printing Decks (5 Working). Printing Type: Solvent-Based, Single-Side. Core Component: Central Impression Drum. Downstream & Auxiliary Equipment: Rewind/Unwind System: Automatic Roll Change At 50 kg, Control/Handling: Automatic Tension Control And Roll Change, Manual Ink Feed And Washing, Drying System: Hot Air With Exhaust Ducting, Hot-Air Drying System, Access: Access Platform With Stairs, Auxiliary Equipment: Exhaust System, Consisting Of 4 Fans With Pipes, Funnels, Etc., Status/Defect: Crane For Roll Replacement Currently Defective. Technical Data (Approx.): Printing Width: Up To 1.200 mm, Printing Repeats Available: 310, 340, 350, 380, 410, 480, 510, 520, 550, 600, 620, 650, 700 mm, Maximum Mechanical Speed: Approx. 200 m/min, Installed Power: Approx. 60 – 70 kW. Overall Dimensions: L 18.000 × W 10.000 × H 7.000 mm. Power Supply: 400 V / 50 Hz / 3 Ph. - LOT 24

![site]()

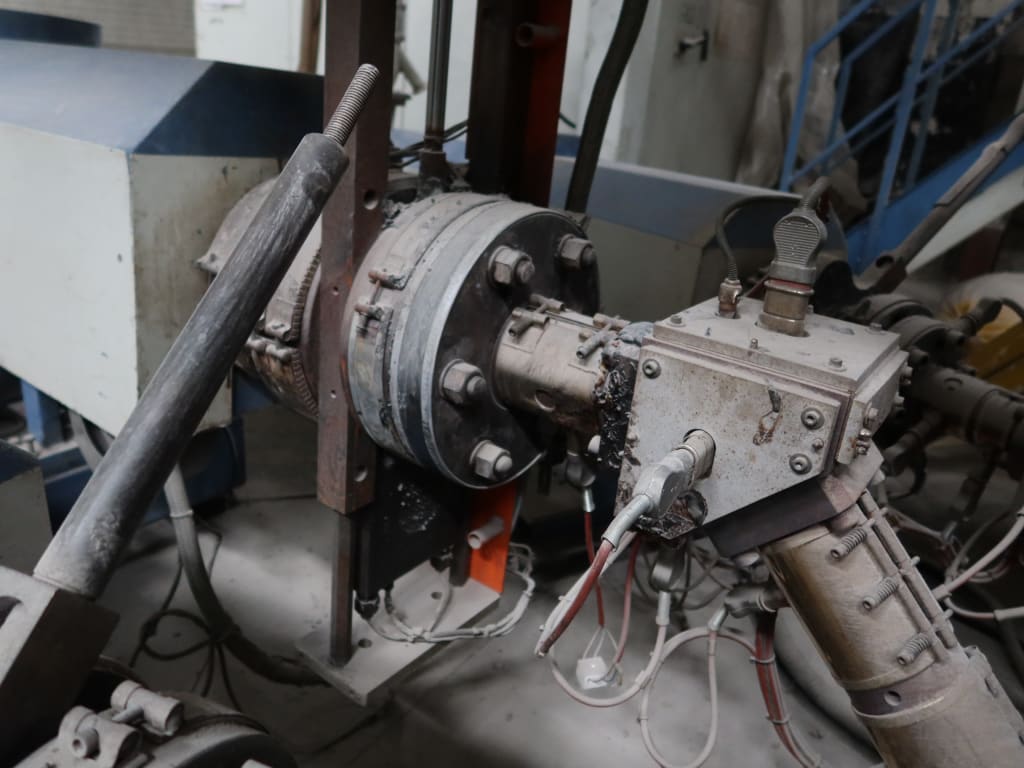

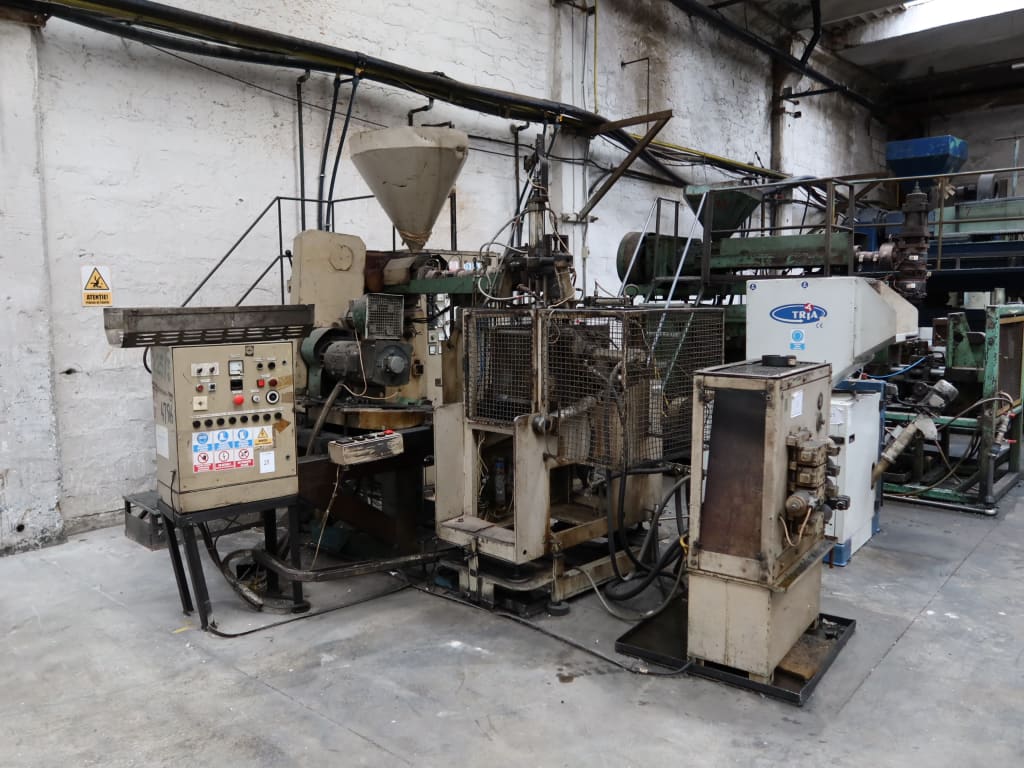

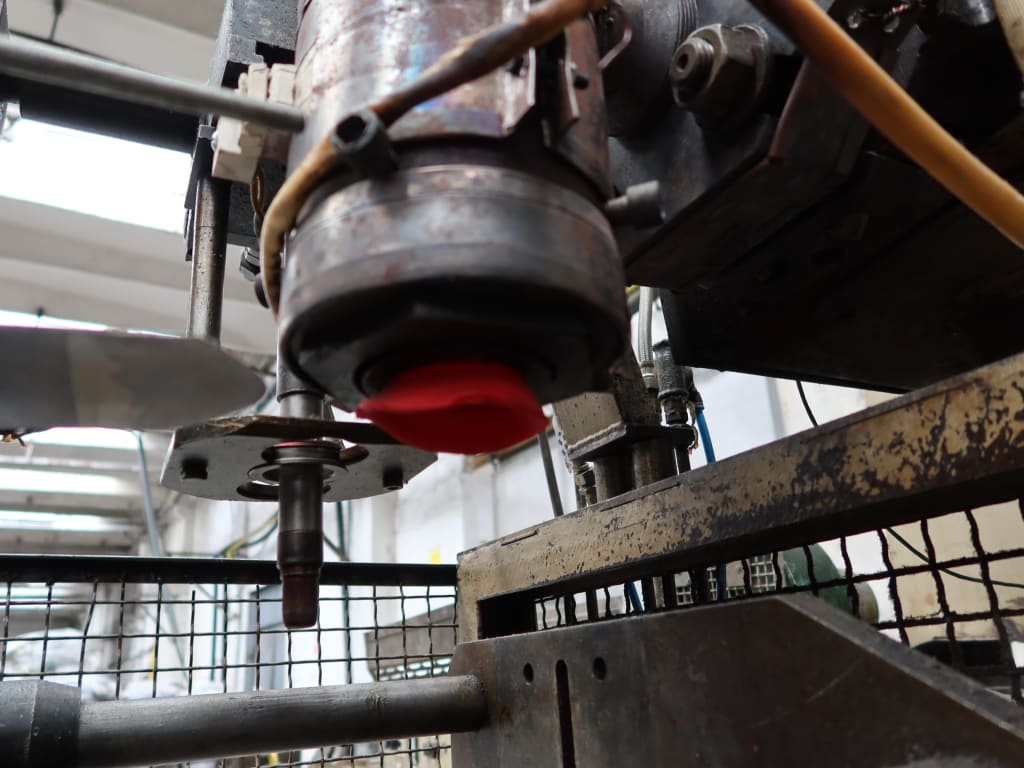

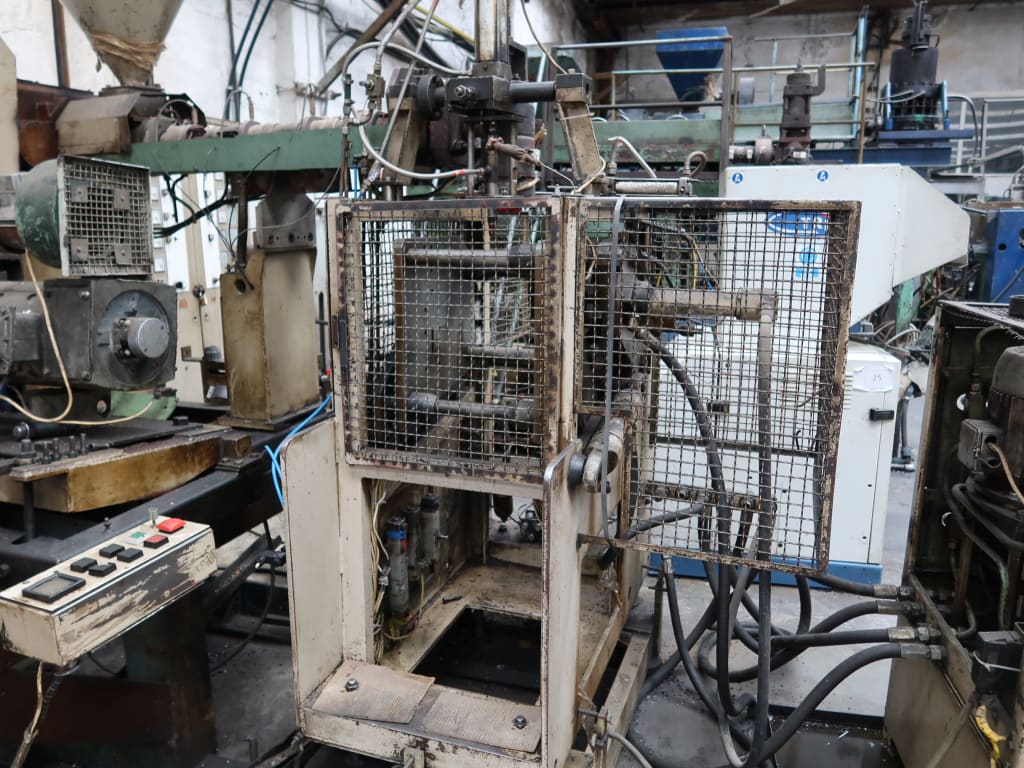

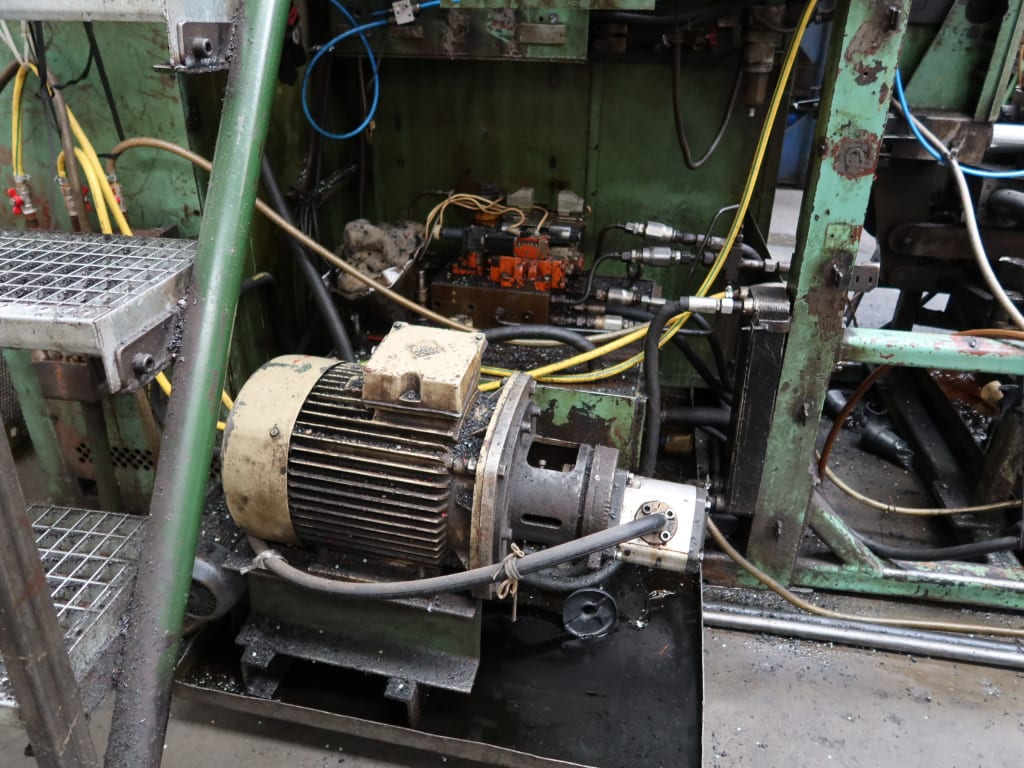

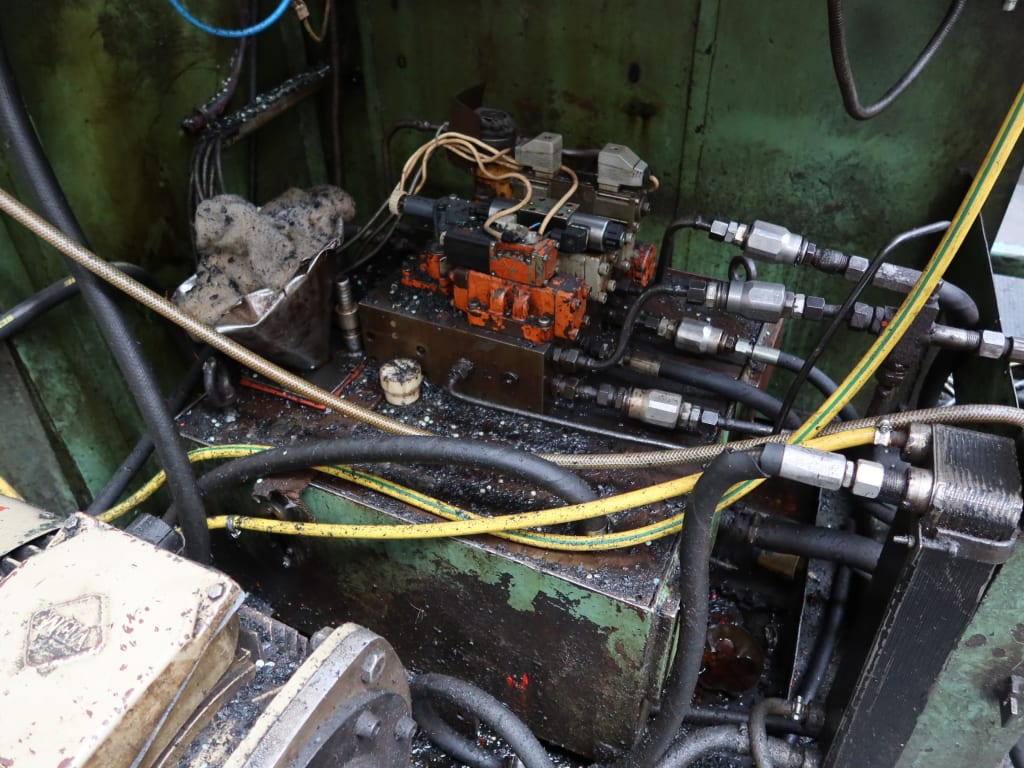

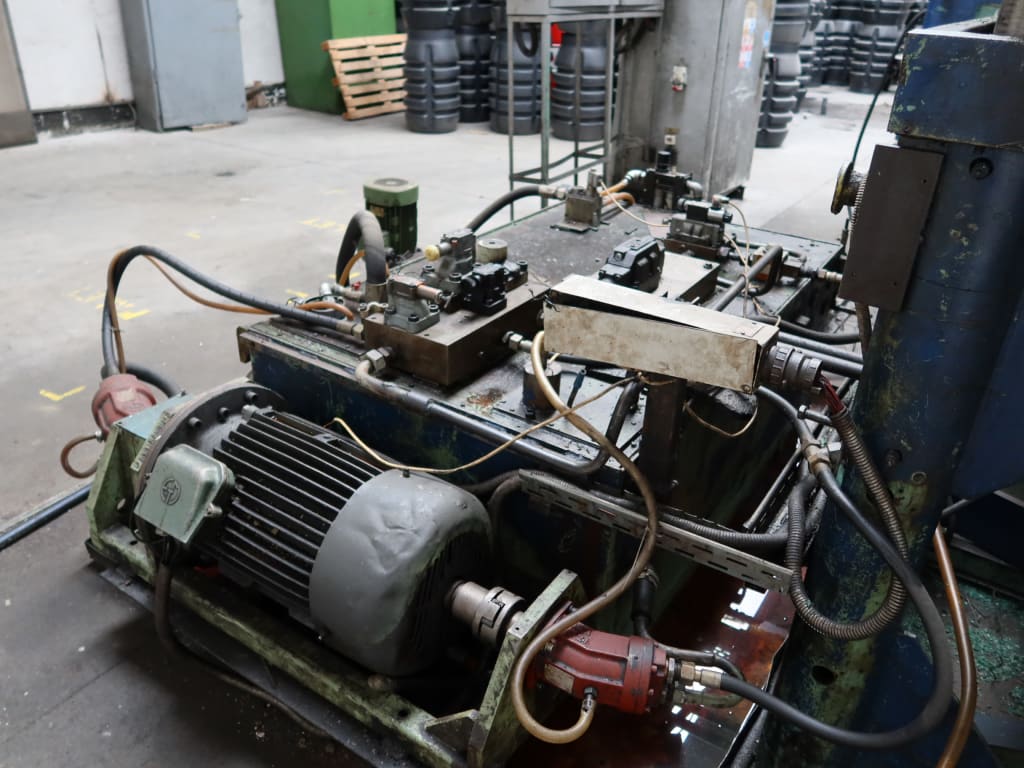

WS BA 2 Extruder Blow Moulding Machine for Jerry Cans/Bottles (1980)

Extrusion Blow Moulding (EBM) Machine, Comprising Of The Following Main Components, Hopper And Screw Extruder. Parison Extrusion Head. Hydraulic Mould Clamping System. Downstream & Auxiliary Equipment: Cooling Circuit, Control Cabinet, Access: Stair Platform For Access. Technical Data (Approx.): Control: Analog, Relay-Based, Drive: Hydraulic With Manual Regulation, Total Connected Load: 3.5 kW, Pneumatic Pressure: 10 bar, Hydraulic Pressure: 160 bar, Machine Weight: ~750 kg. Overall Dimensions: L 5.000 × W 3.000 × H 3.000 mm. Power Supply: 220 V / 50 Hz. - LOT 25

![site]()

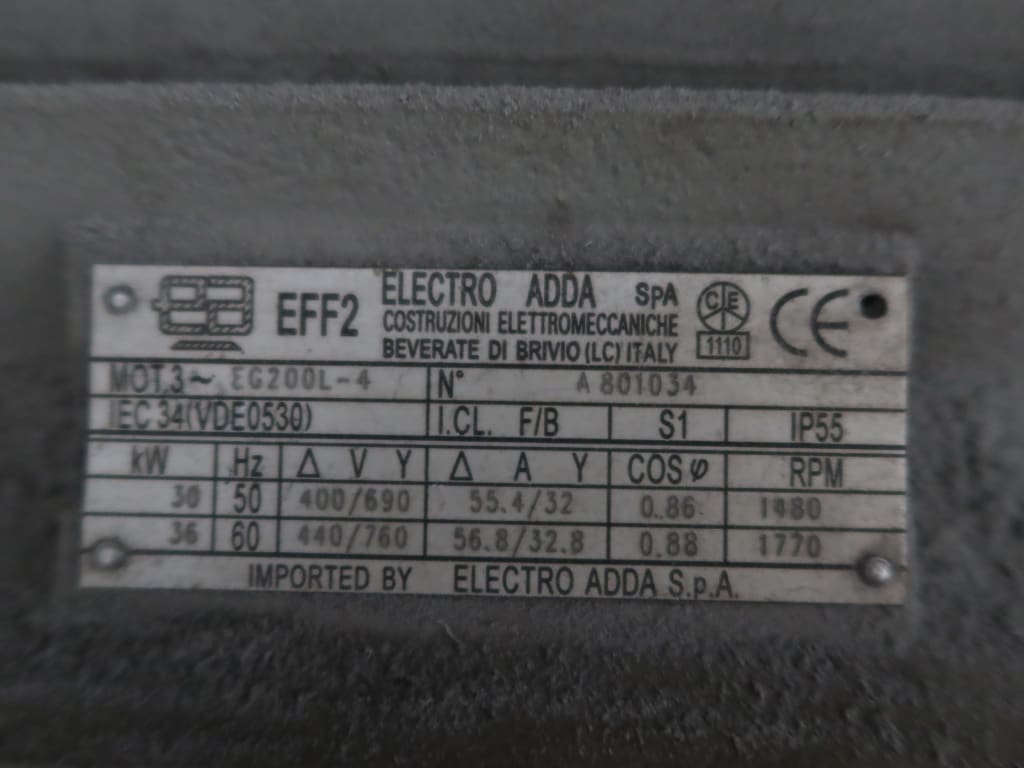

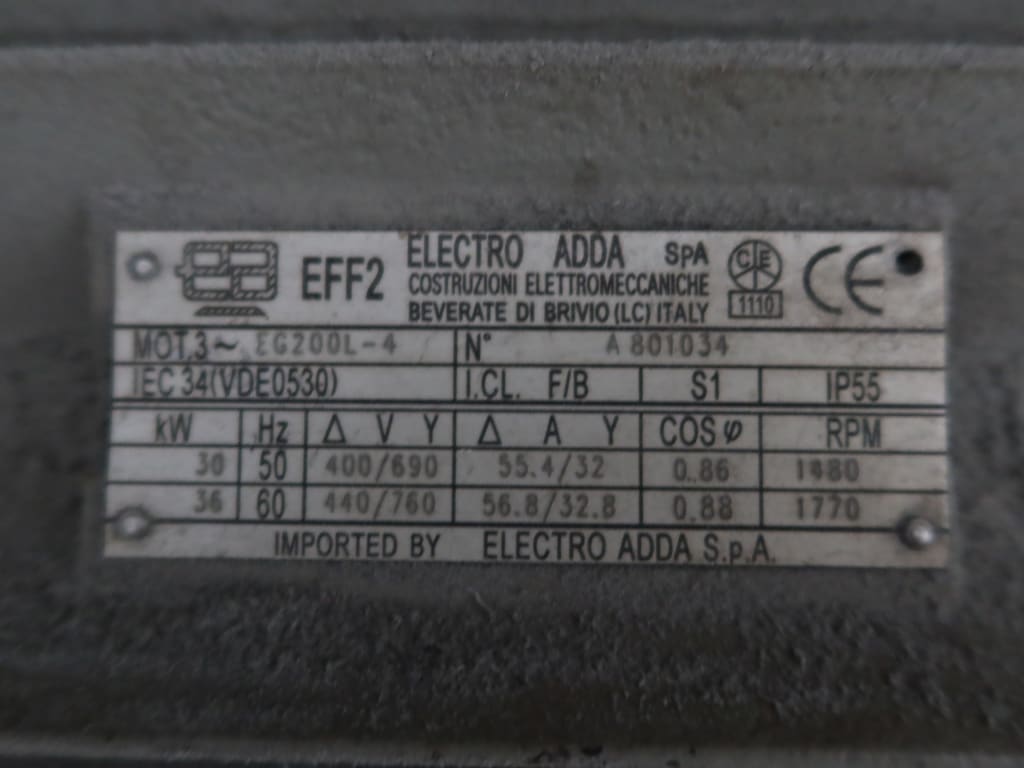

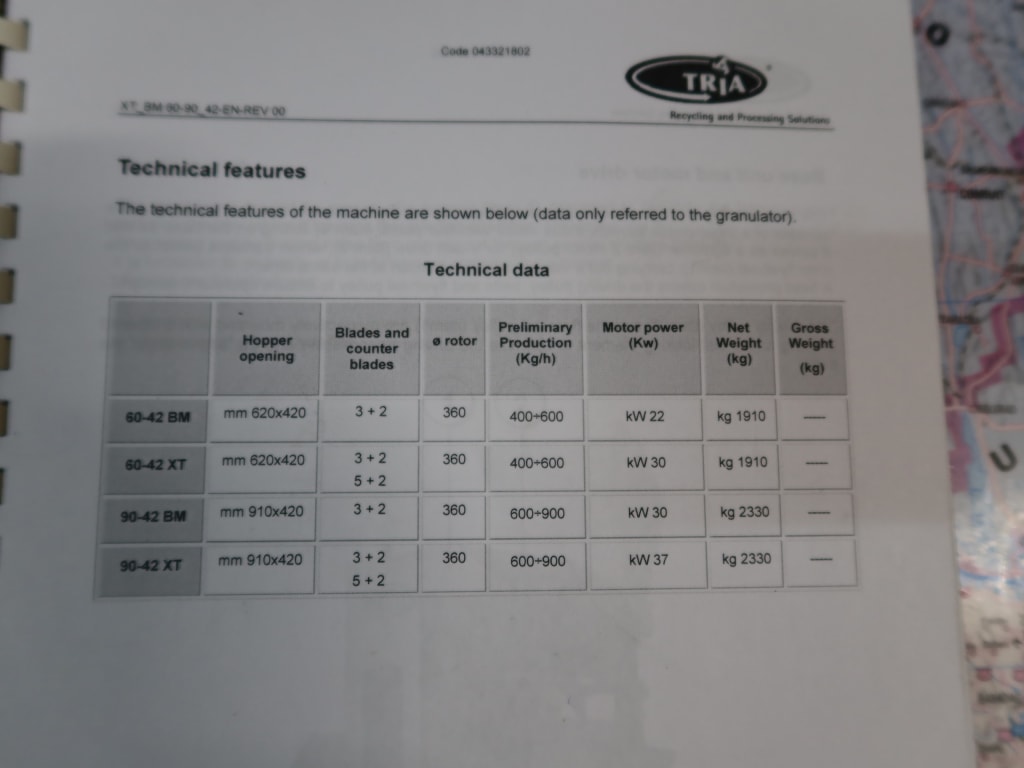

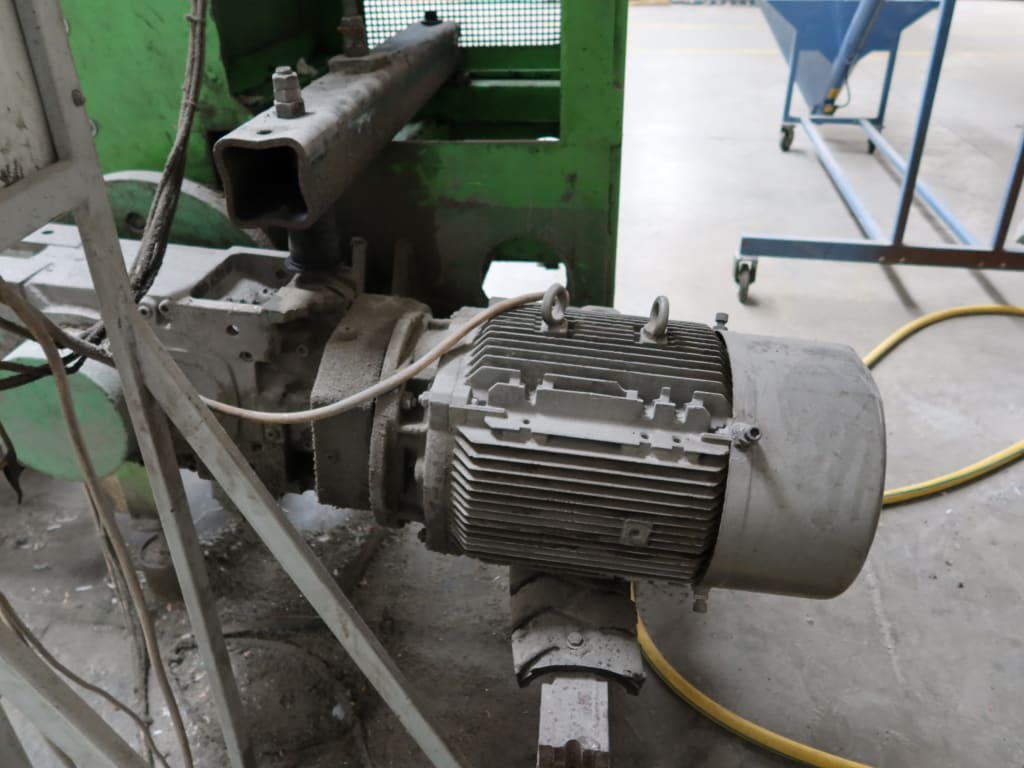

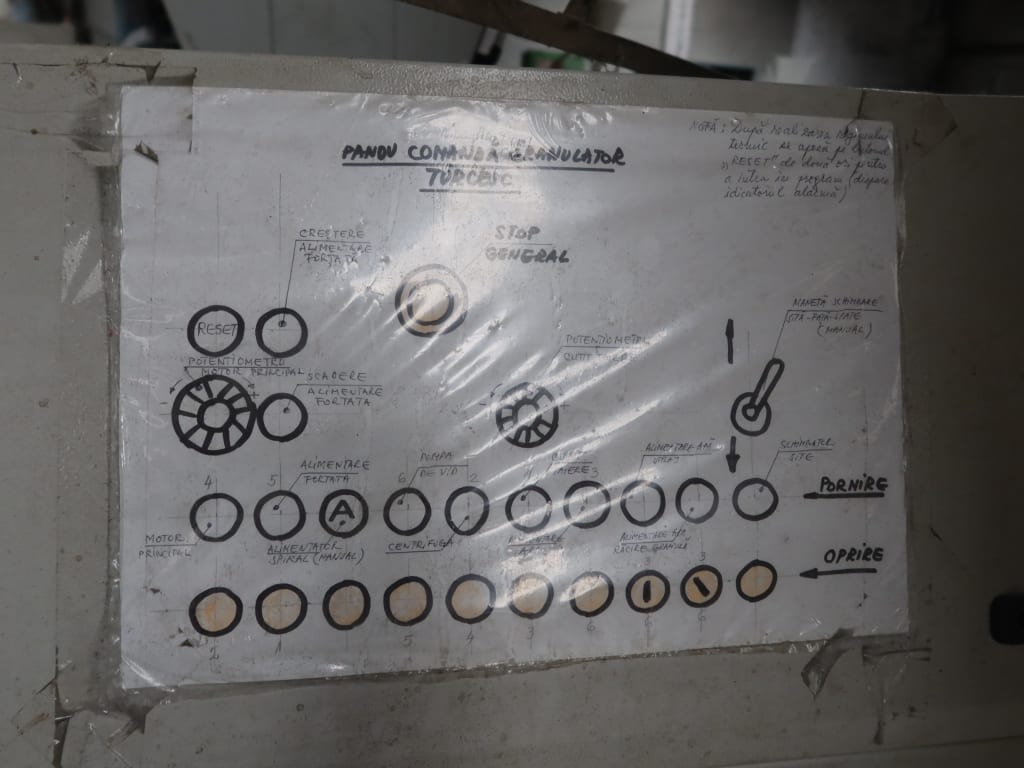

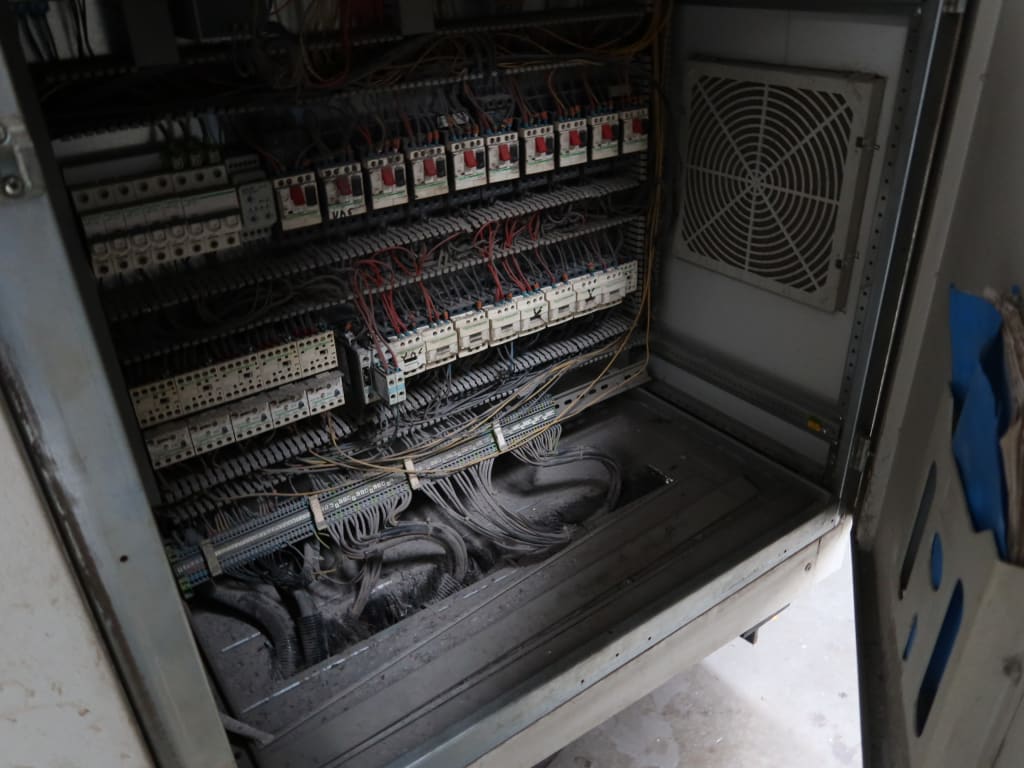

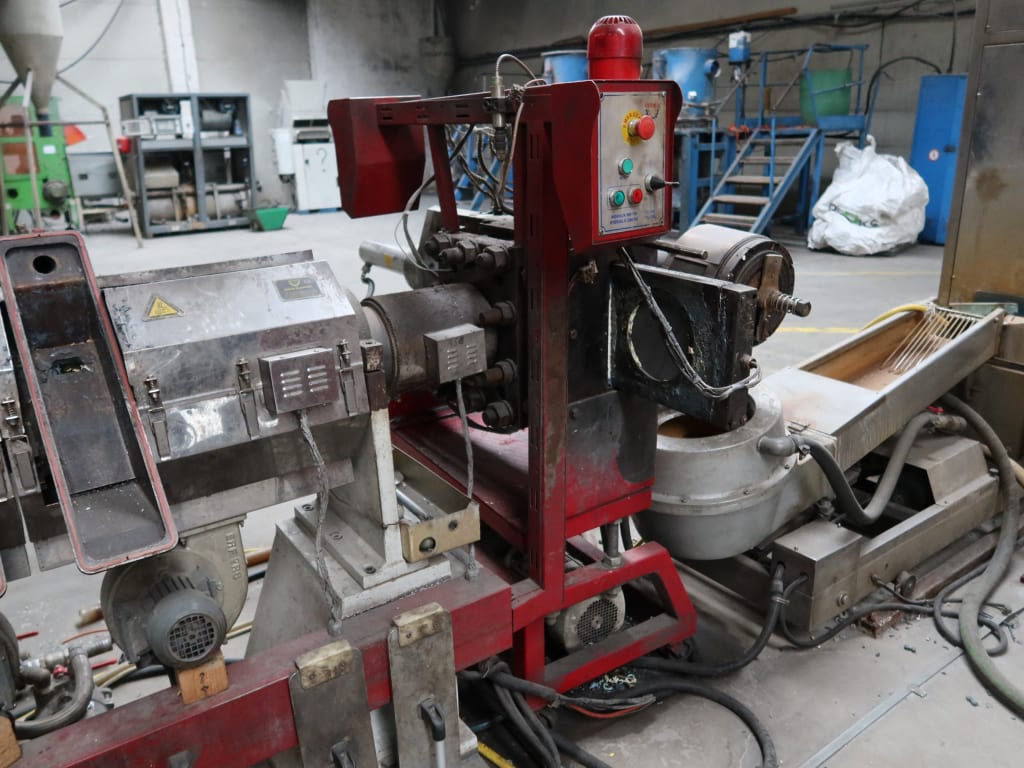

TRIA 60-42 XT Plastic Granulator/Grinder

Granulator/Grinder Machine (High Speed Rotor), Comprising Of The Following Main Components, Hopper Opening: 620 × 420 mm. Rotor Diameter: 360 mm. Blades: 3 Rotor + 2 Fixed (Optionally 5 + 2). Motor: 30 kW (Electro Adda EG200L-4). Downstream & Auxiliary Equipment: Feed: Manual Or Conveyor, Discharge: Pneumatic Outlet With Pipe Coupling, Noise Enclosure: Yes. Technical Data (Approx.): Production Rate: 400 – 600 kg/h, Approx. Weight: 1.910 kg, Rotor Speed: ≈ 1.800 rpm. Overall Dimensions: L 1.500 × W 1.200 × H 1.800 mm. Power Supply: 400 V / 690 V, IP55. - LOT 26

![site]()

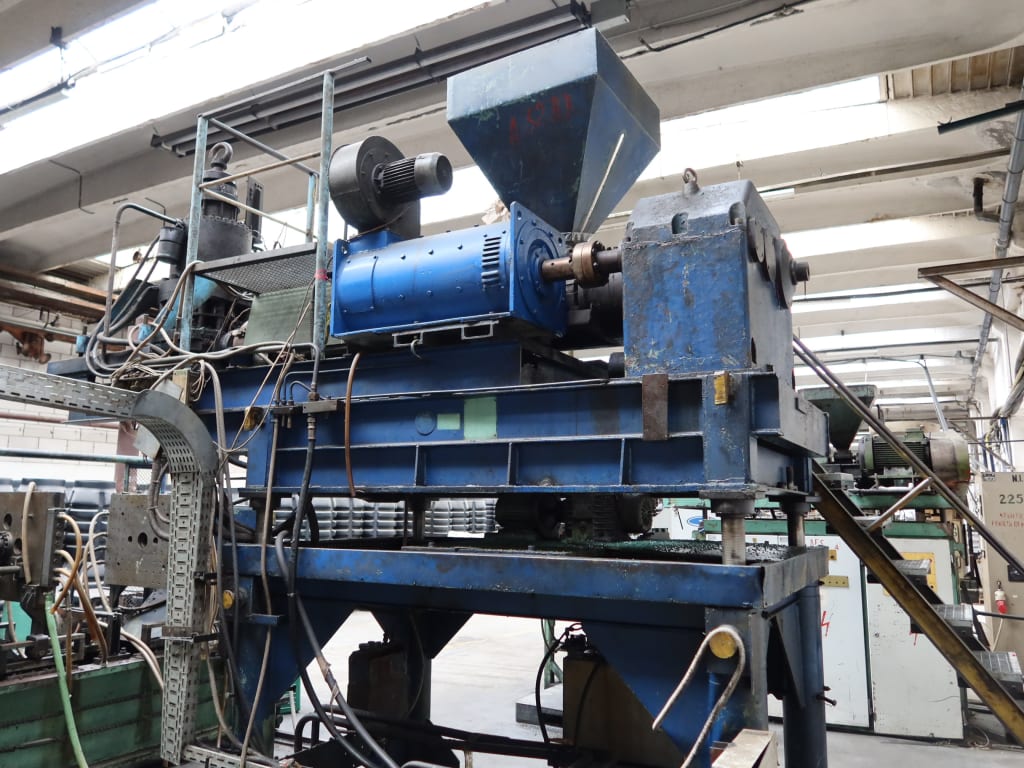

IPTE AFS 5 Blow Moulding Machine (1984)

Extrusion Blow Moulding (EBM) Machine (2–5 Litre Capacity), Comprising Of The Following Main Components, Extruder Type: Single Screw. Mould Clamping Unit: Hydraulic, 2 Halves. Downstream & Auxiliary Equipment: Control System: Relay-Type Electrical Cabinet. Technical Data (Approx.): Max. Container Volume: Approx. 2–5 Litres (Depending On Mould), Hydraulic Pressure: 160 bar, Pneumatic Pressure: 10 bar, Installed Power: ~35 kW (Estimated). Overall Dimensions: L 5.000 × W 3.000 × H 3.500 mm. Power Supply: 380 V / 50 Hz. - LOT 27

![site]()

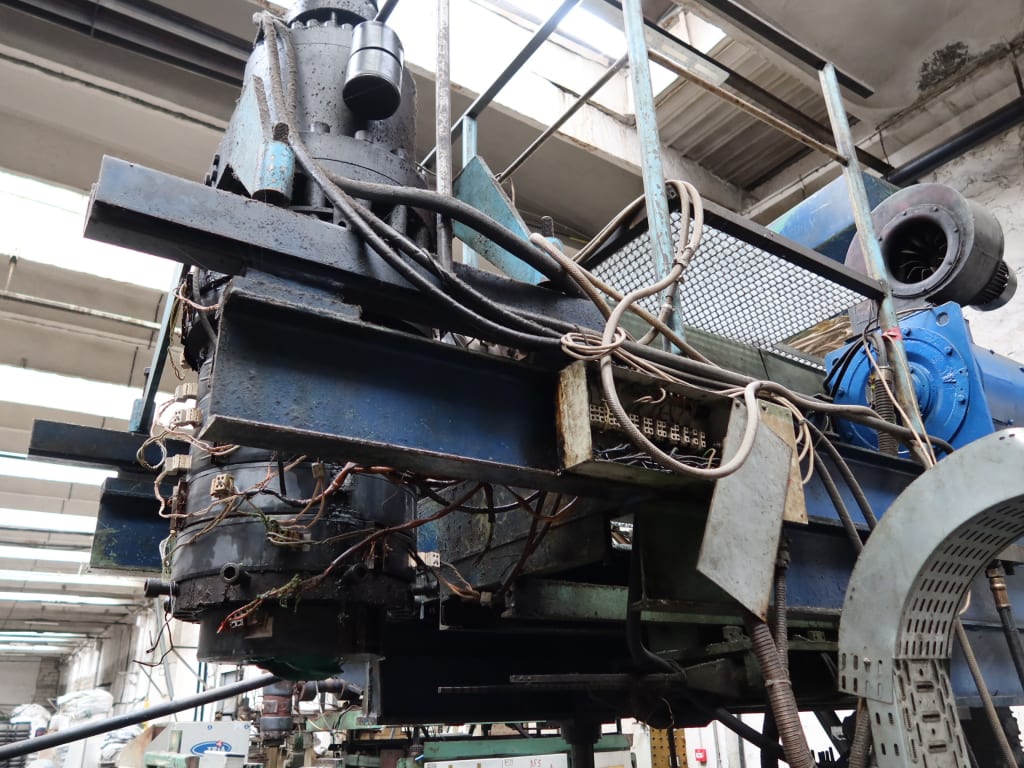

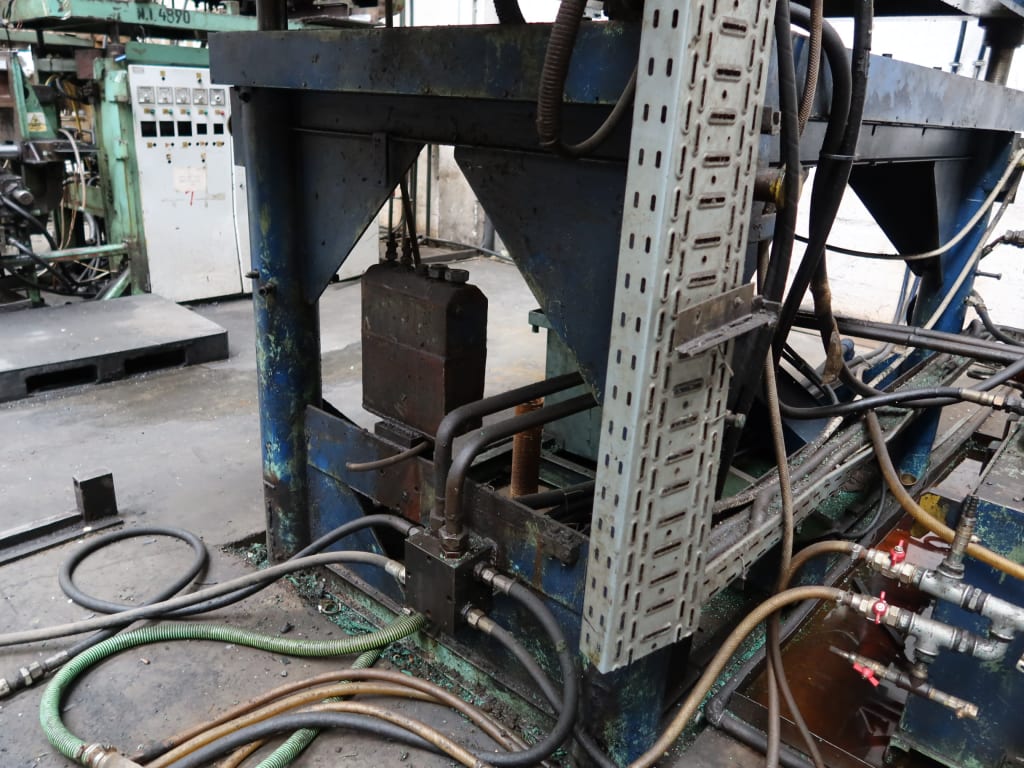

Blow Moulding Machine for Large Containers

Extrusion Blow Moulding (EBM) Machine (10 Litre, Accumulator Head), Comprising Of The Following Main Components, Extruder Type: Single Screw With Accumulator Head. Mould Clamping System: Hydraulic. Downstream & Auxiliary Equipment: Typical Product Example: Jerrycan (Photo Reference), Max. Mould Width: ~400 mm. Technical Data (Approx.): Max. Container Volume: ~10 L. Overall Dimensions: L 7.000 × W 5.000 × H 5.000 mm. Power Supply: 380 V / 50 Hz. - LOT 28

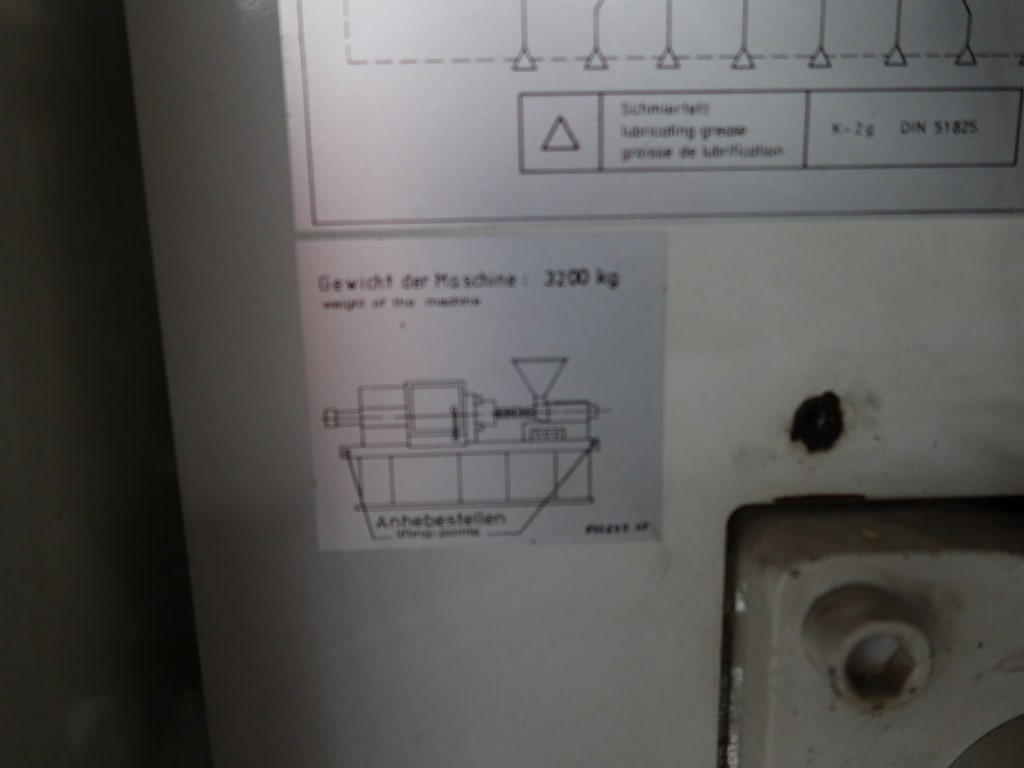

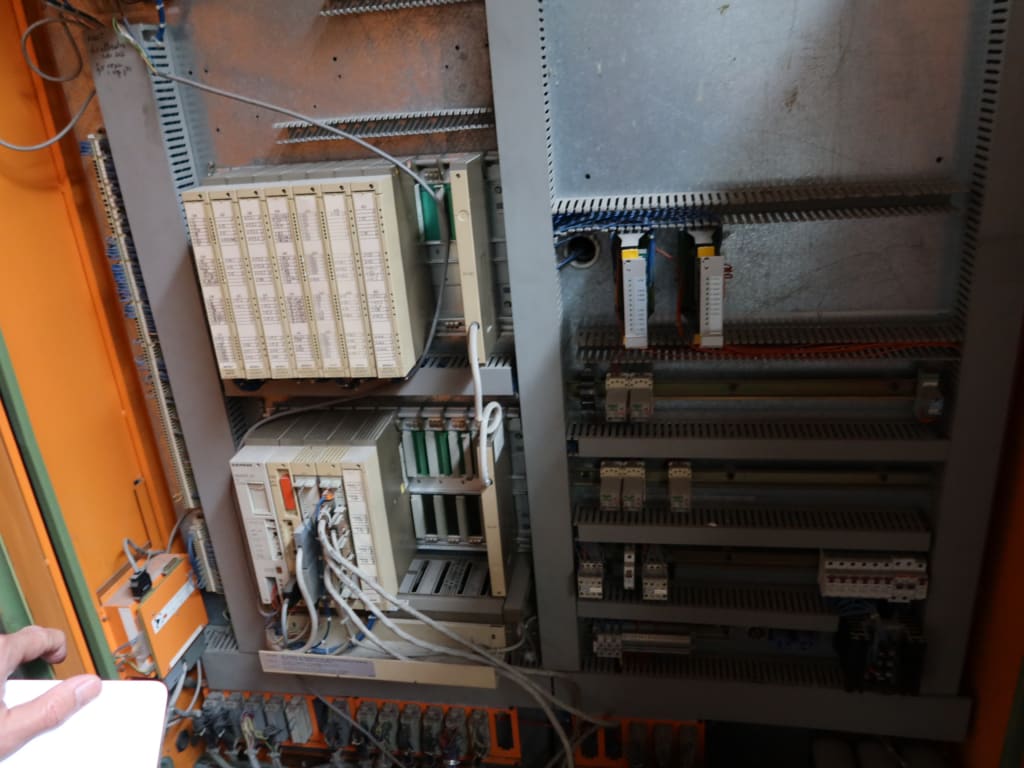

![site]()

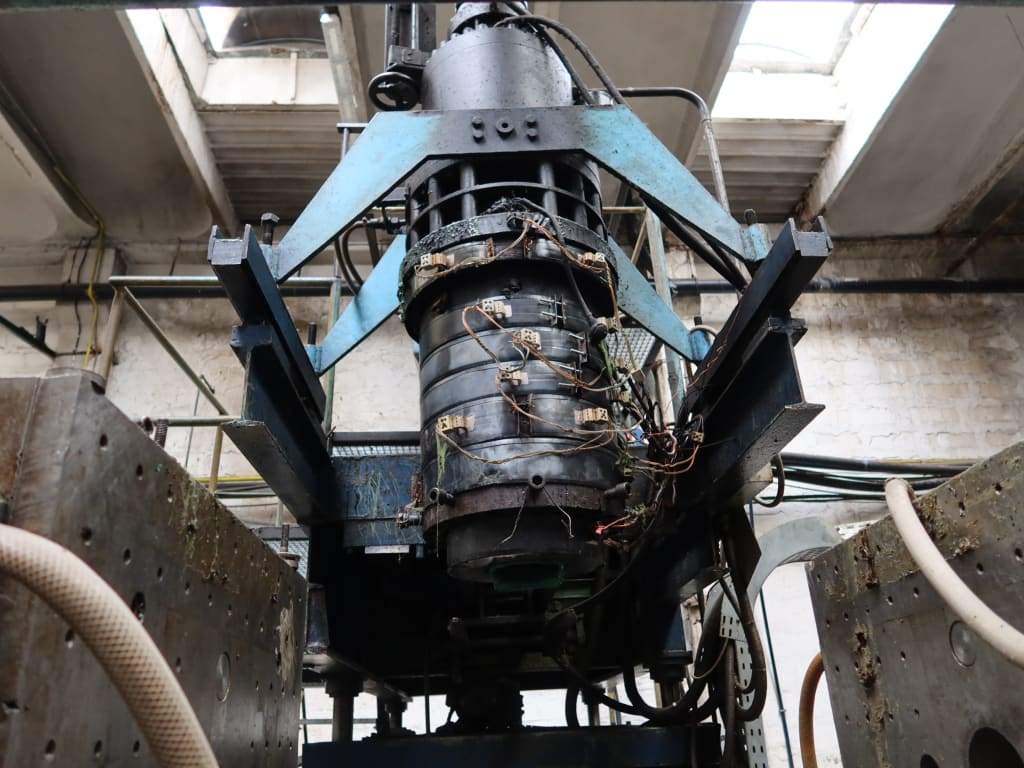

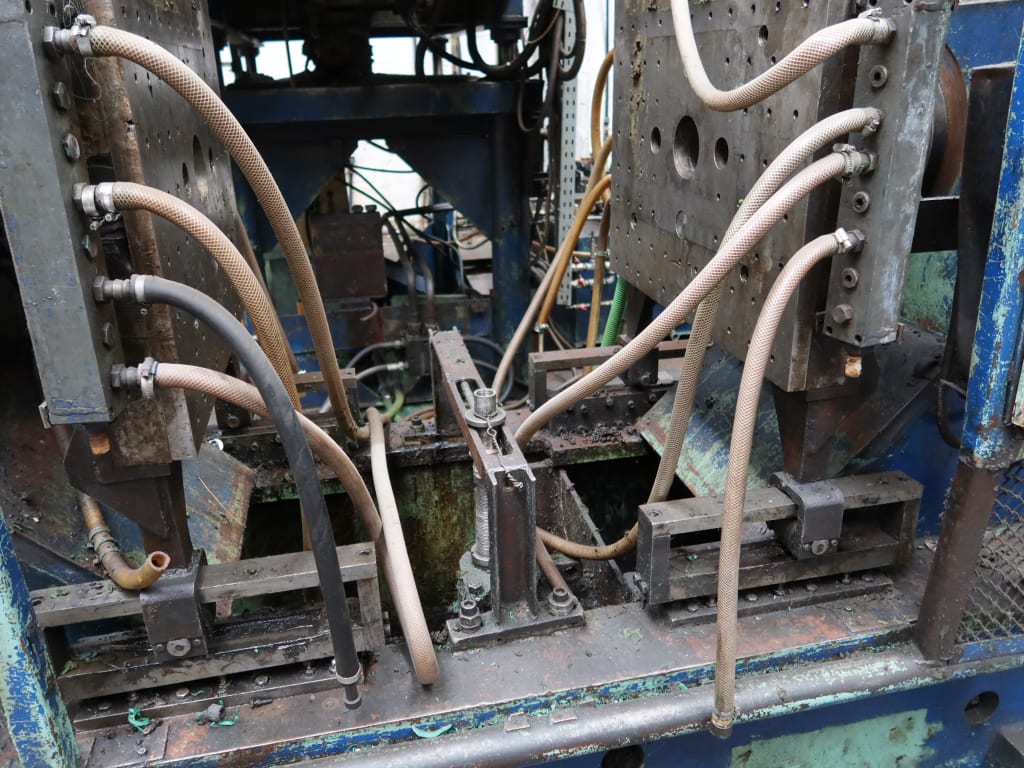

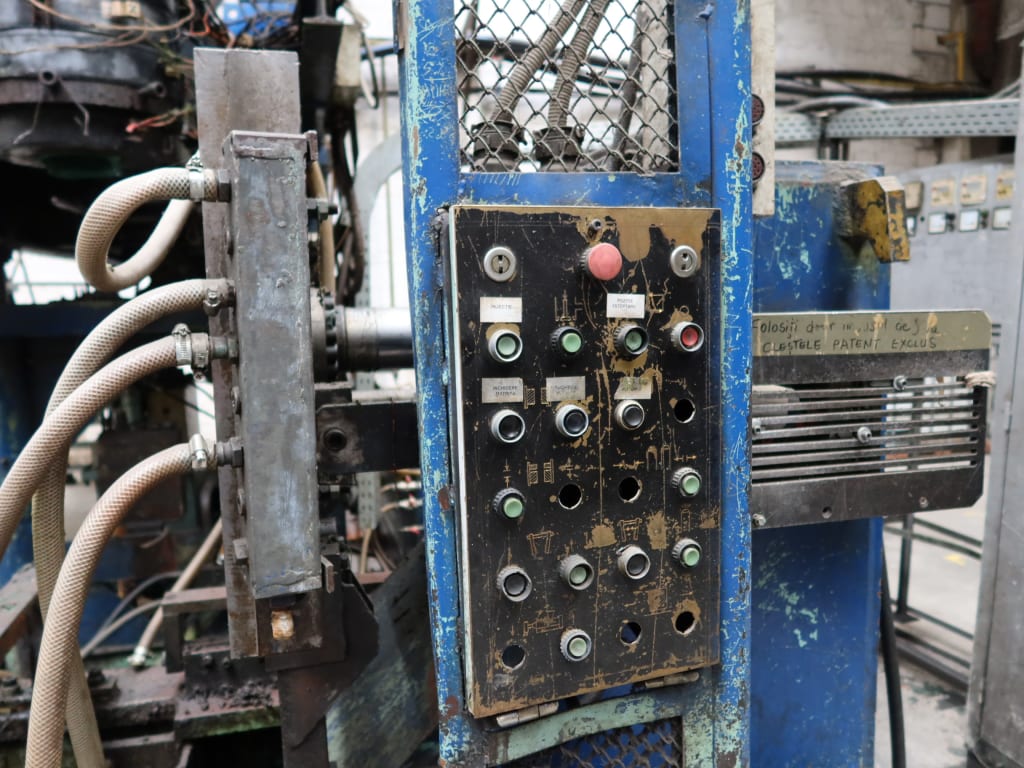

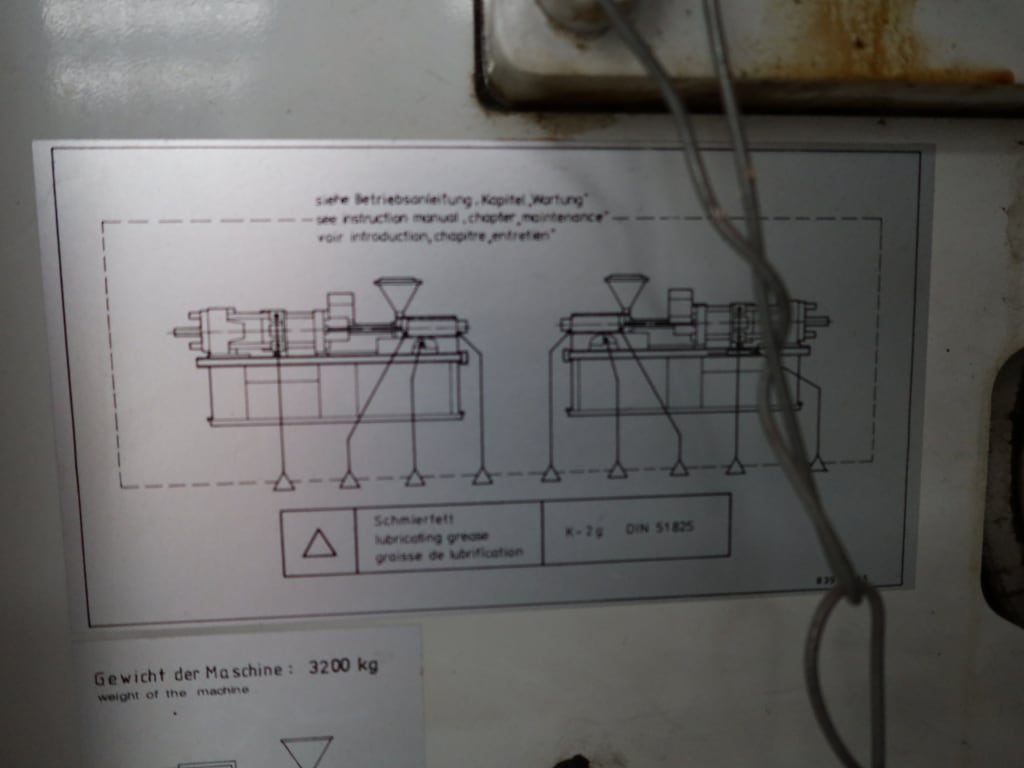

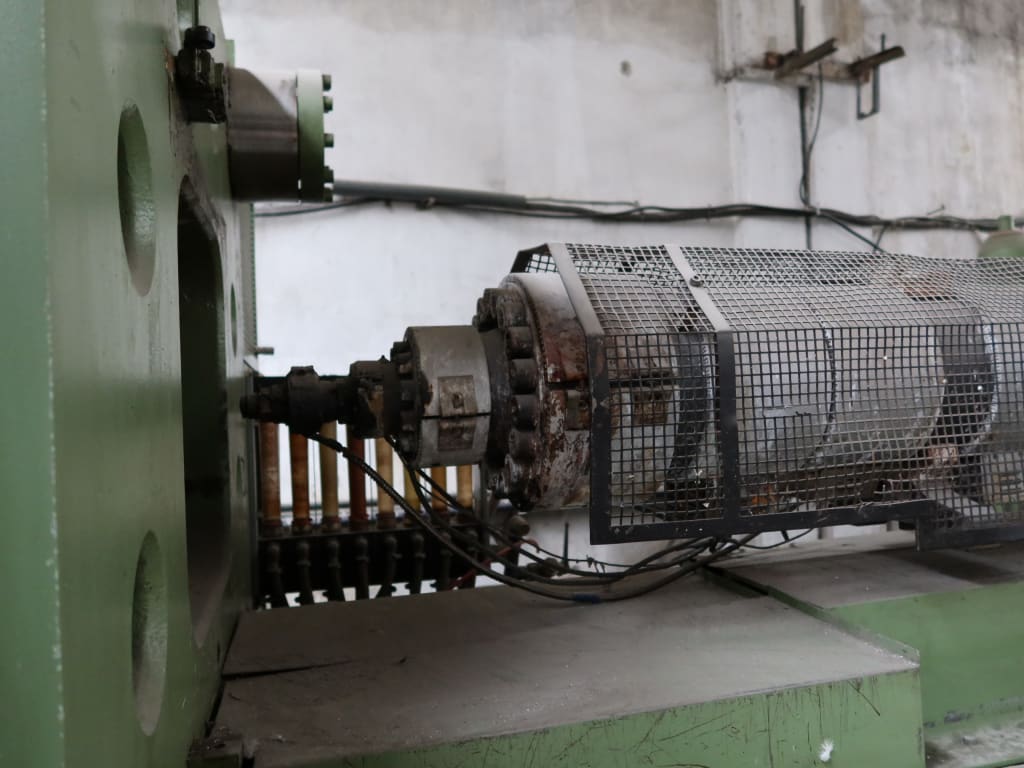

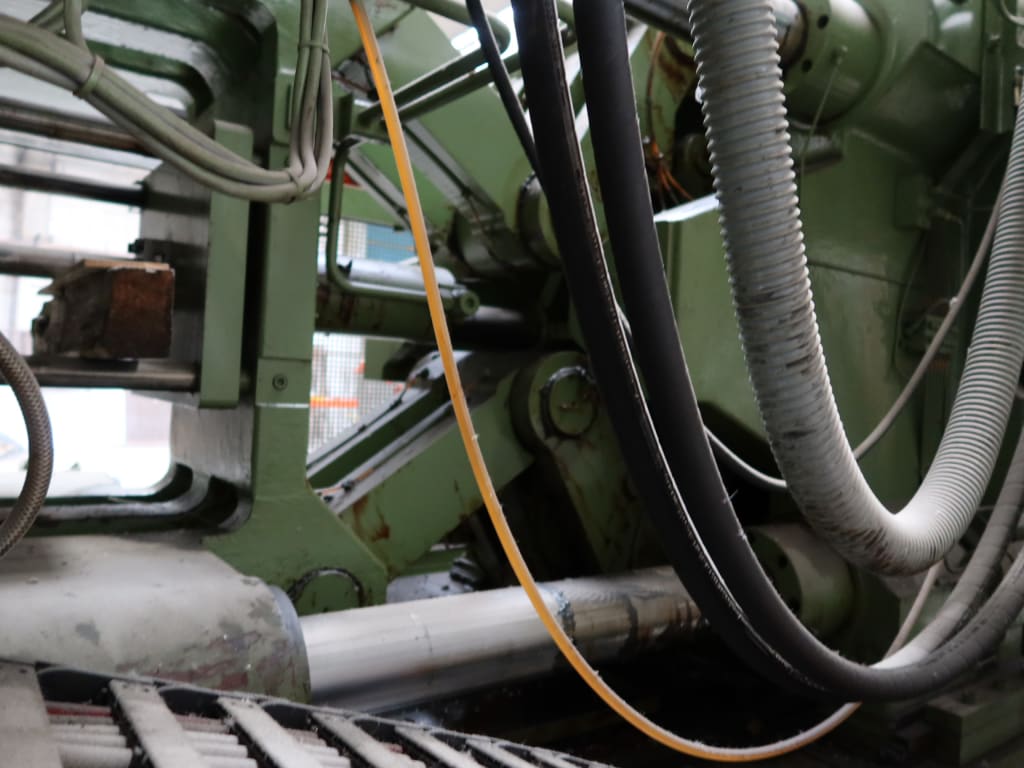

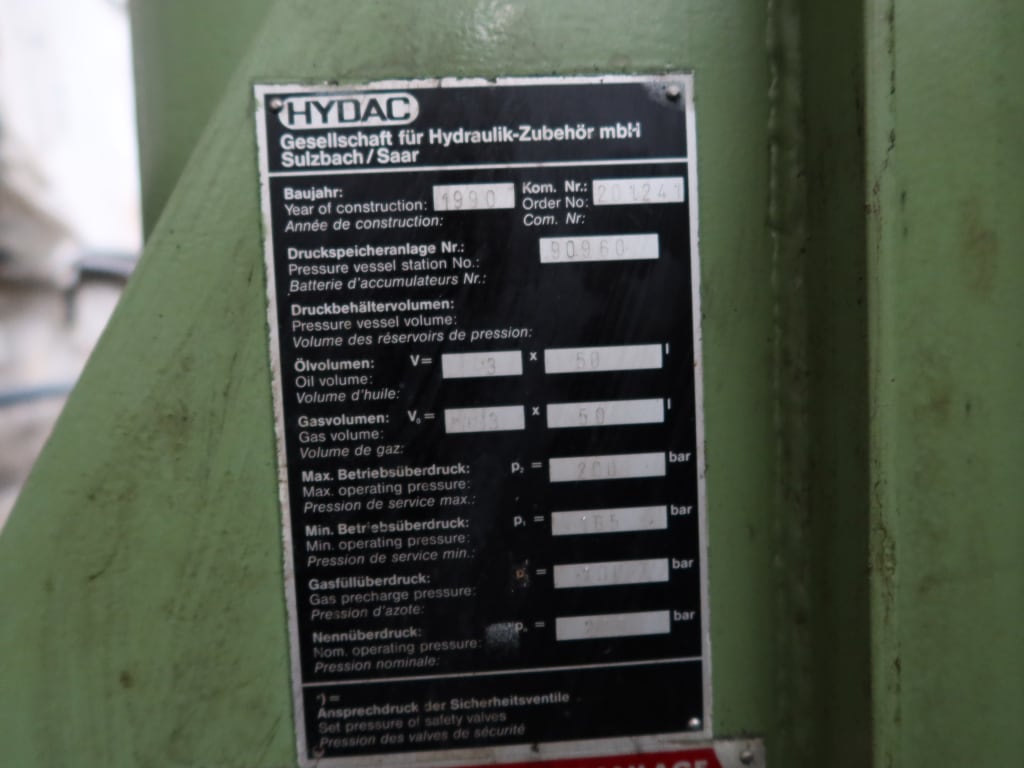

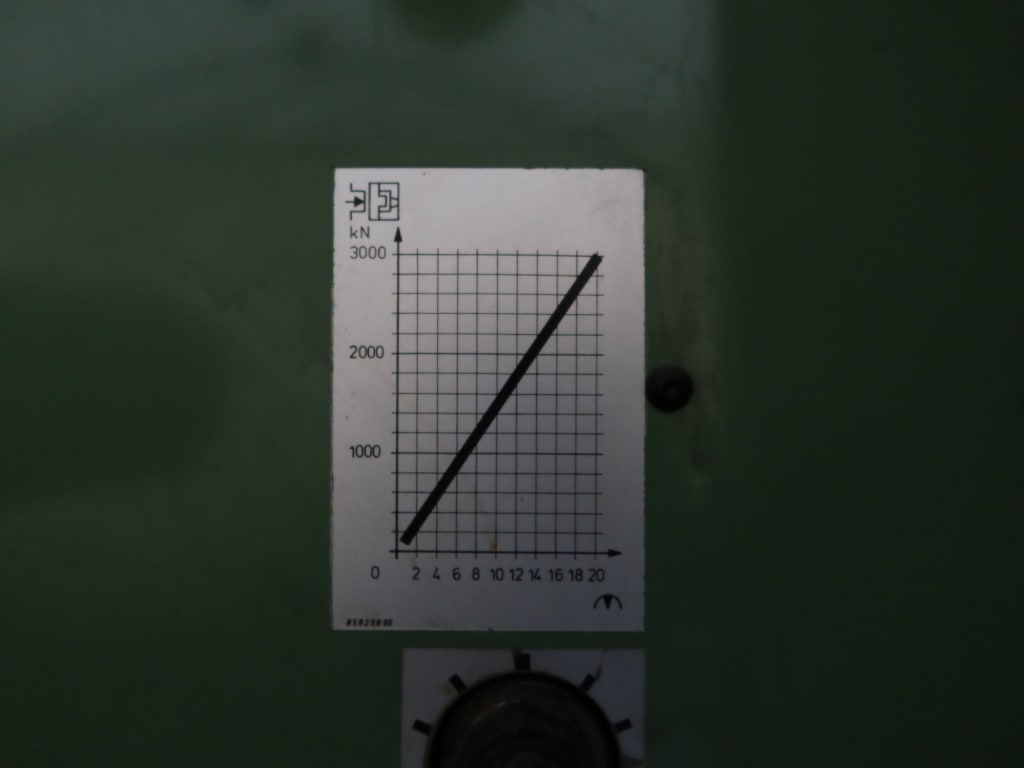

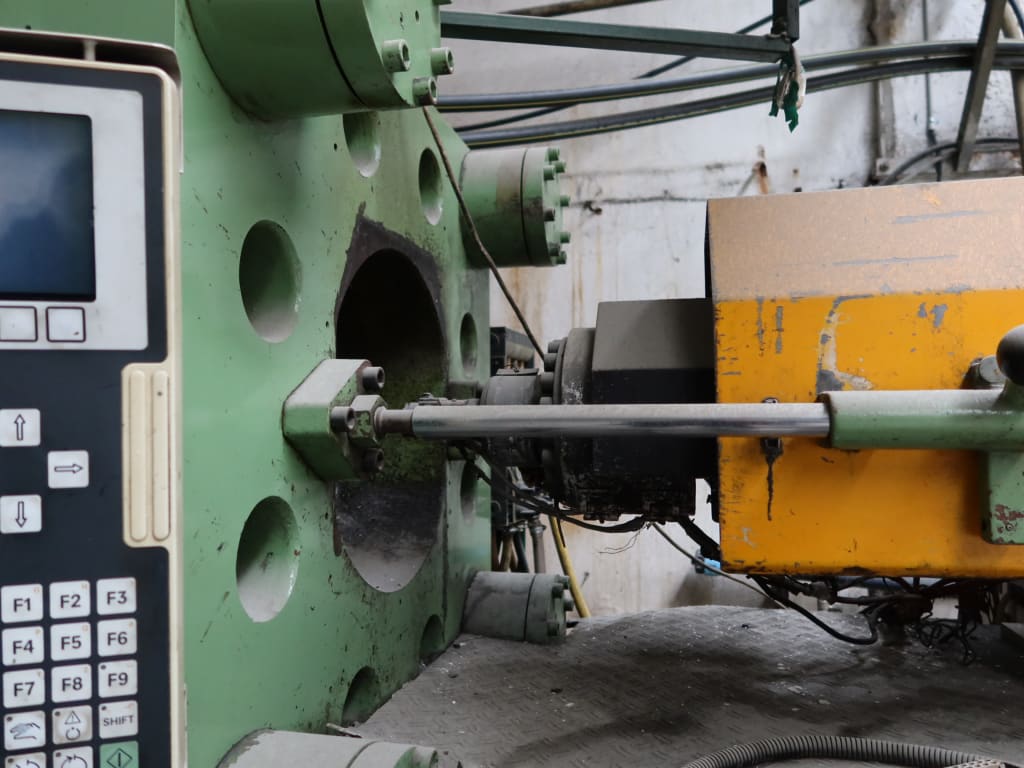

MANNESMANN DEMAG D 60-275 NCIII-S Injection Moulding Machine (1992)

Injection Moulding Machine (IMM) (275 Ton Clamping Force), Comprising Of The Following Main Components, Clamping Force: 2.750 kN (≈ 275 Tons). Screw Diameter: 60 mm. Downstream & Auxiliary Equipment: Control System: NCIII-S. Technical Data (Approx.): Shot Weight (PS): Approx. 540 g, Distance Between Tie Bars: ~600 × 600 mm, Opening Stroke: ~500 mm, Mould Height: 200 – 500 mm, Injection Pressure: Up To 1.600 bar, Approx. Weight: 3.2 t. Overall Dimensions: L 5.500 × W 1.500 × H 2.000 mm. Power Supply: 3 × 400 V / 50 Hz. - LOT 29

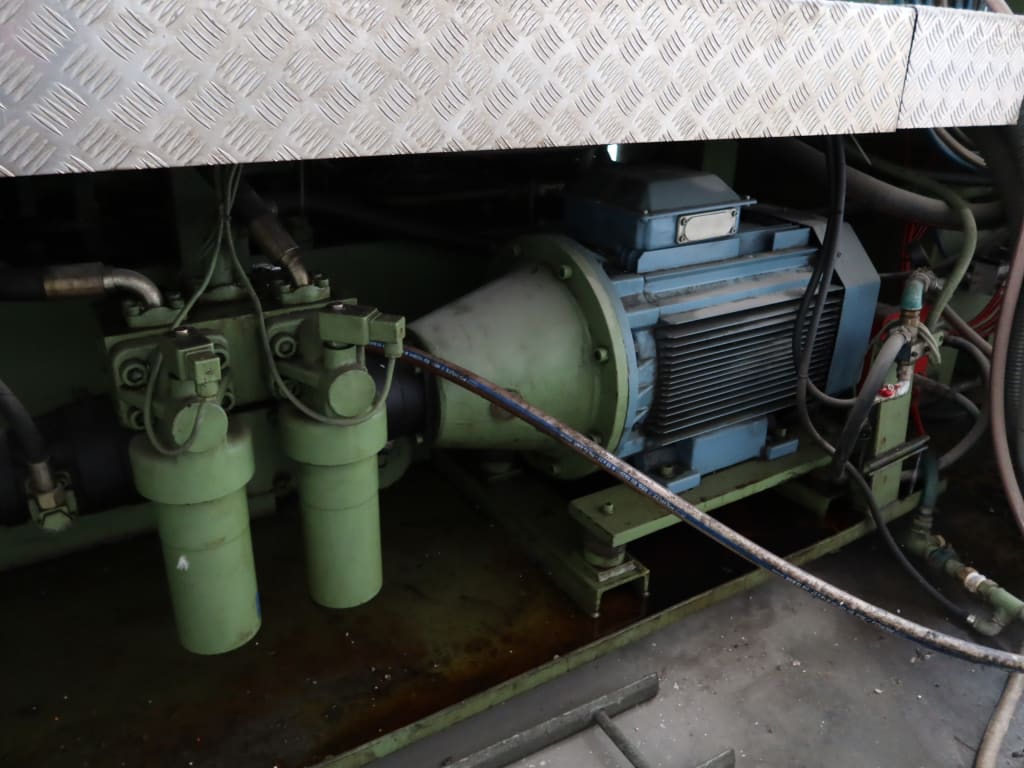

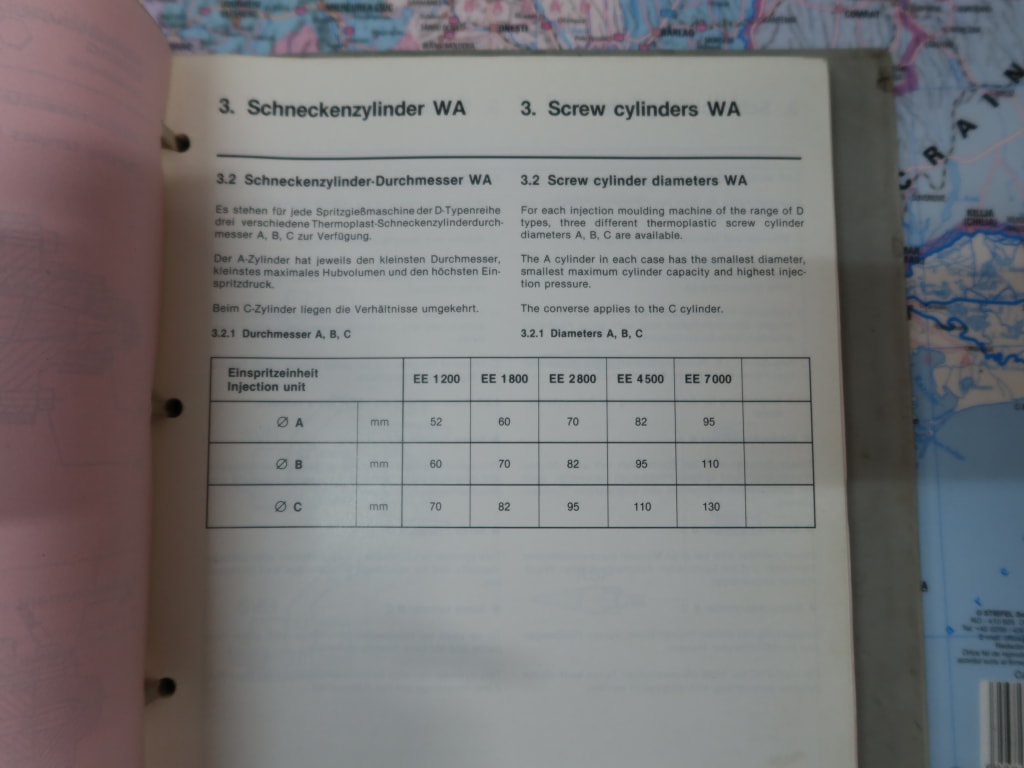

![site]()

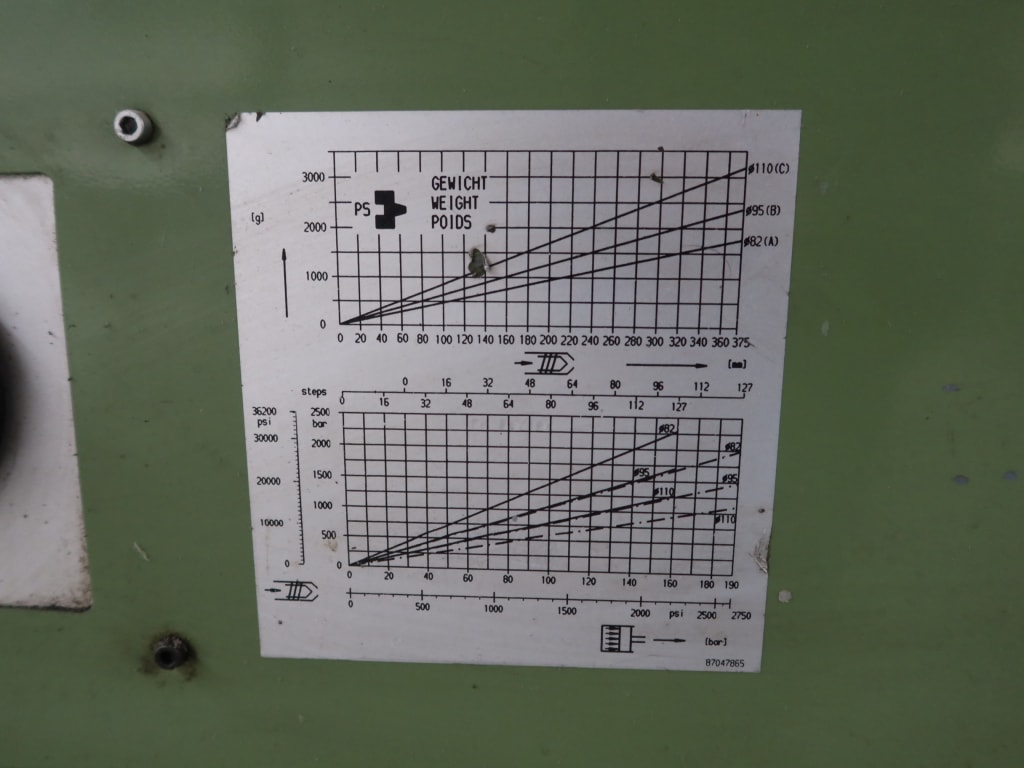

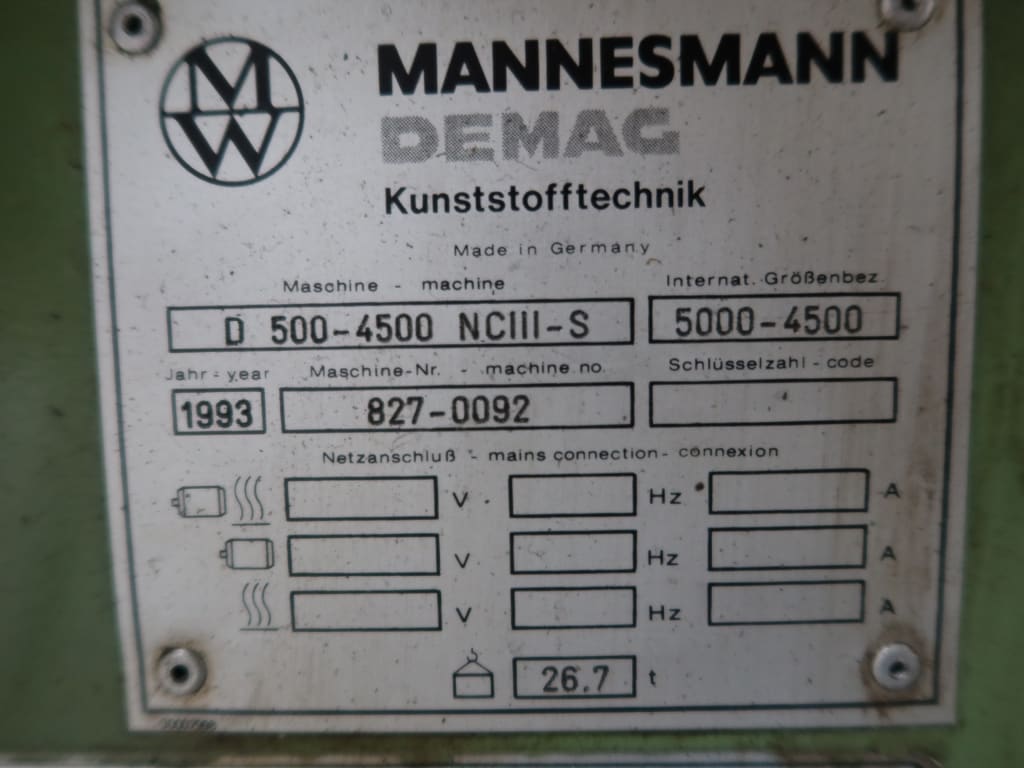

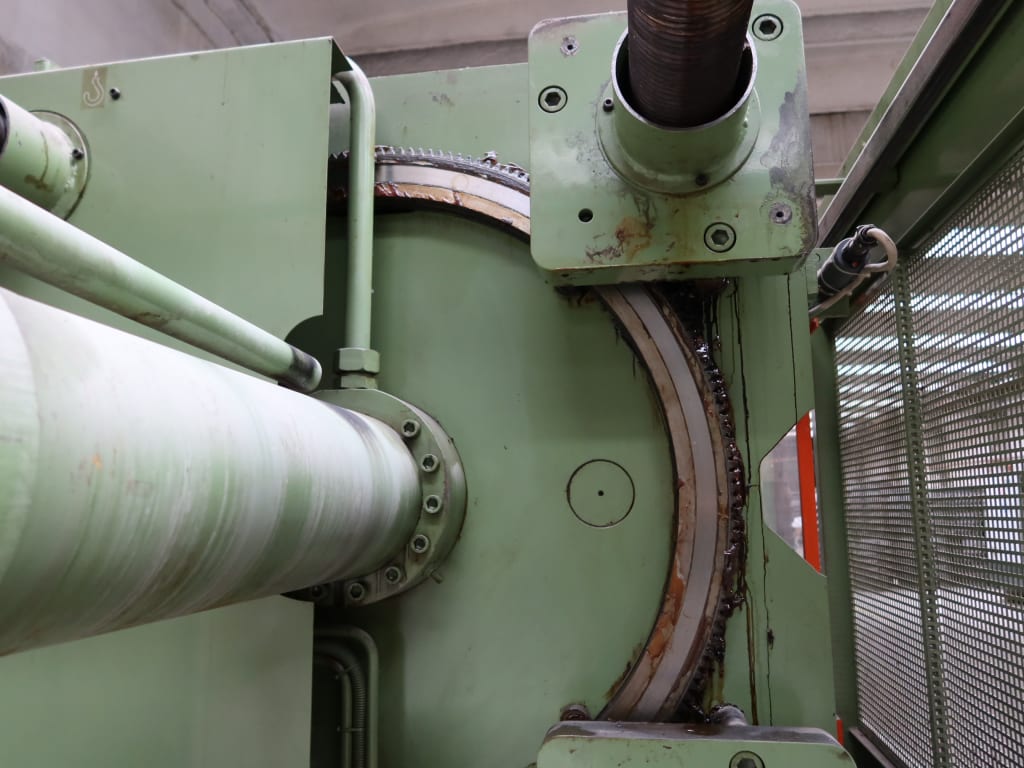

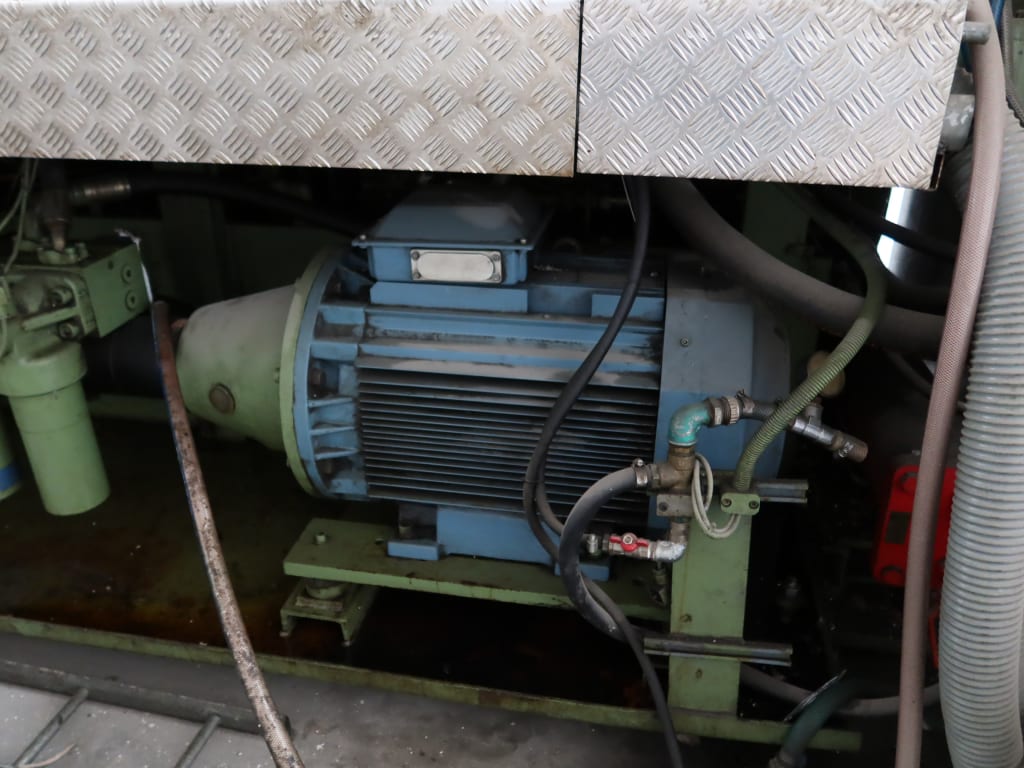

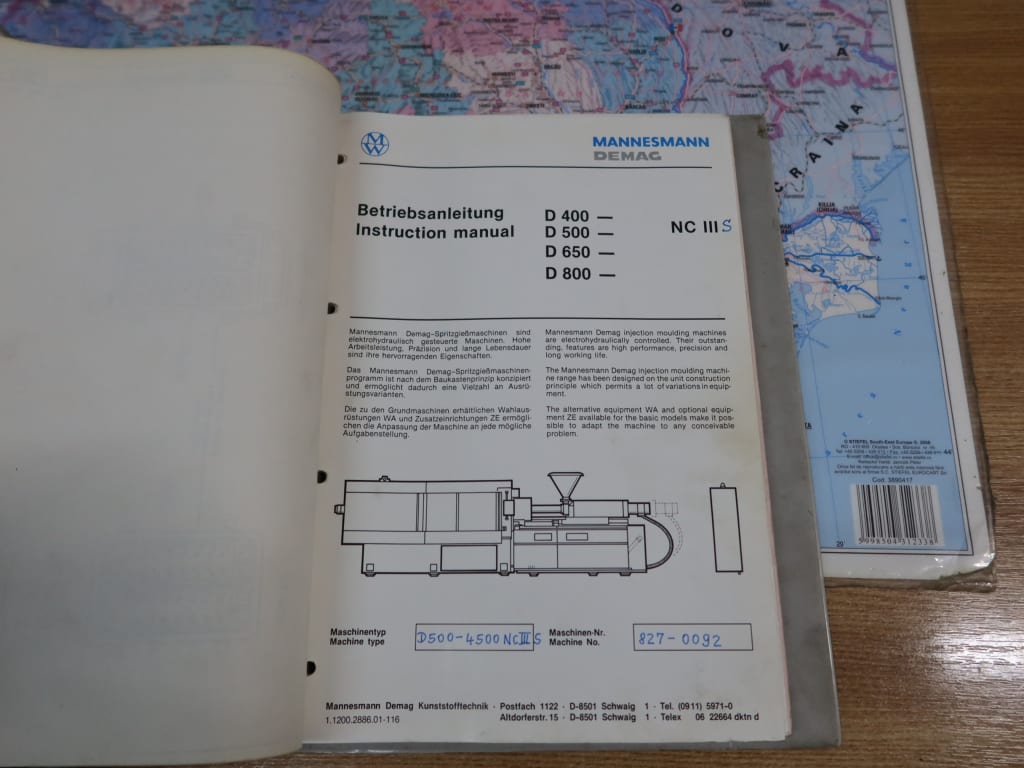

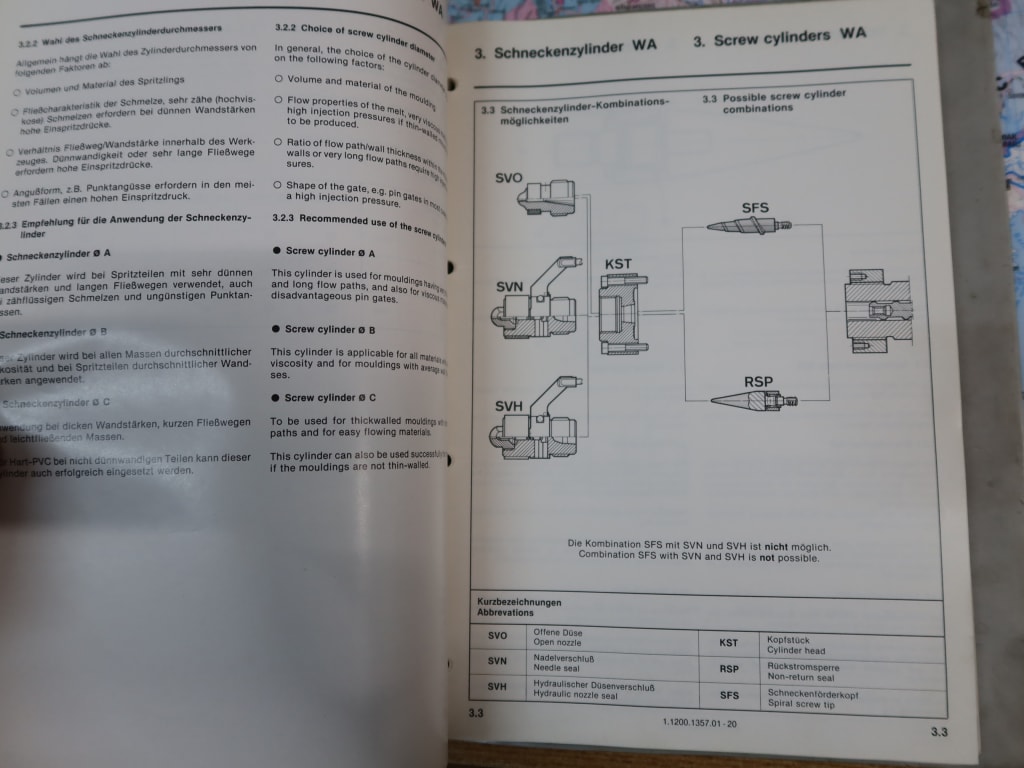

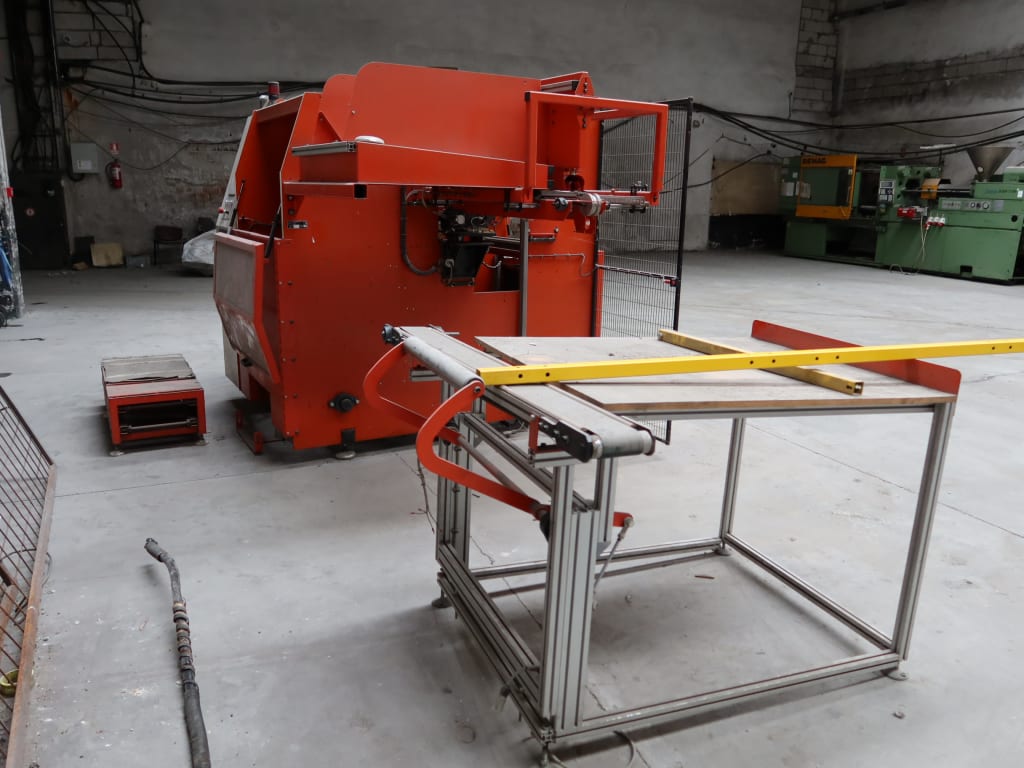

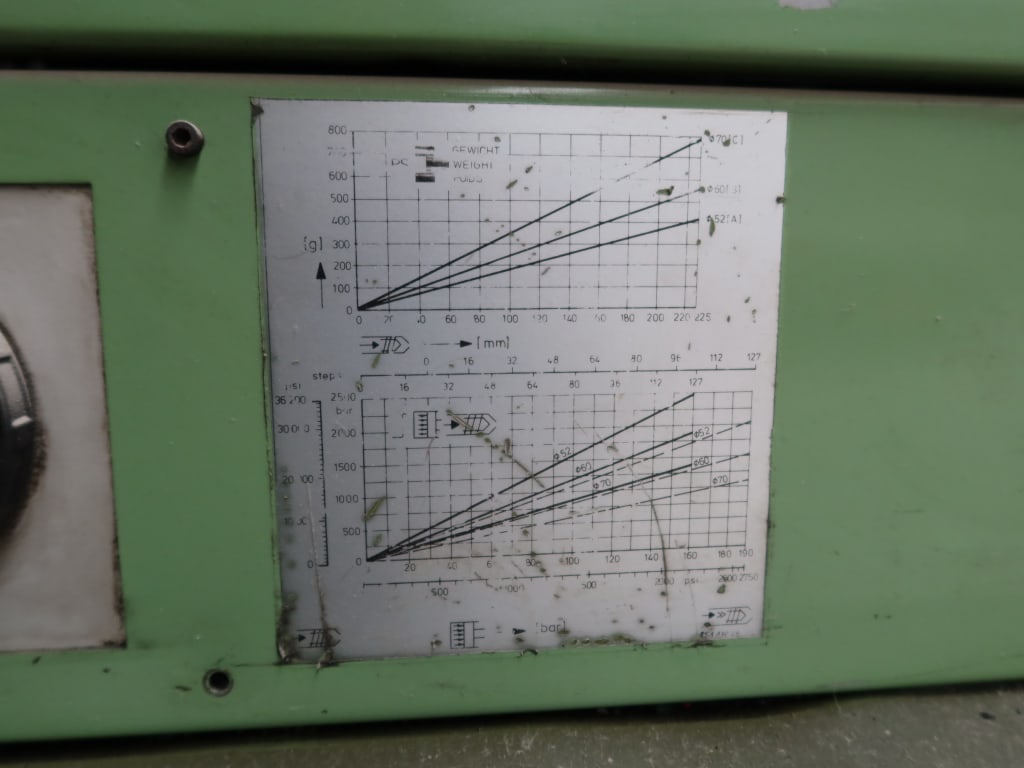

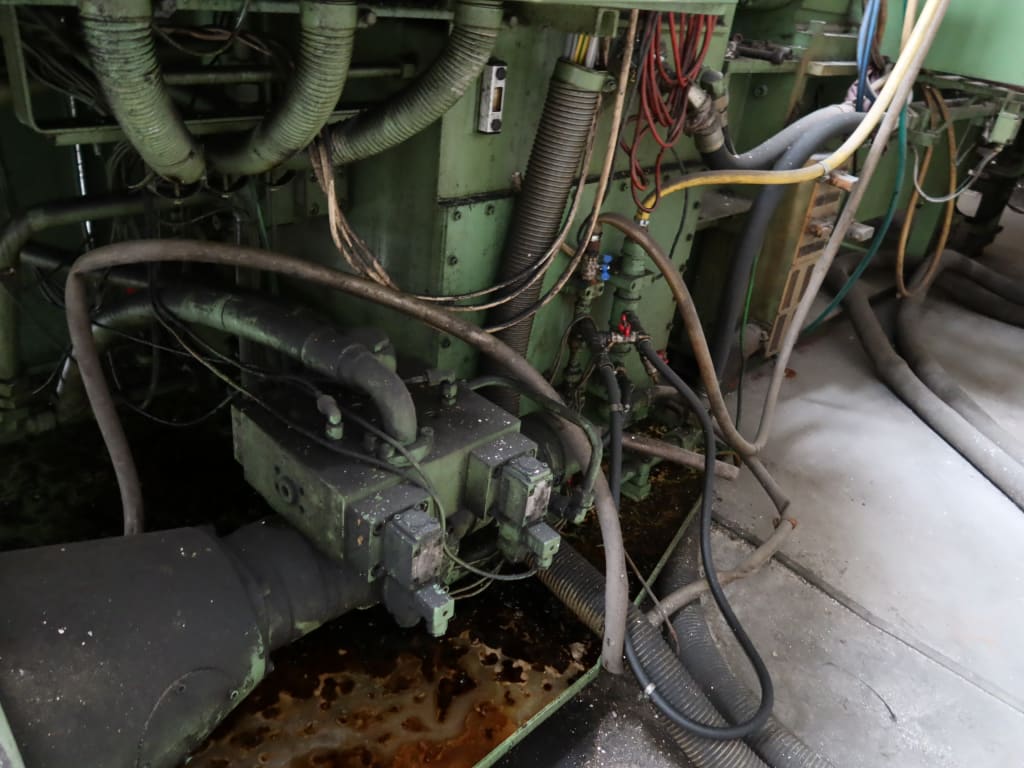

MANNESMANN DEMAG D 500-4500 NCIII-S Injection Moulding Machine (1993)

Injection Moulding Machine (IMM) (450 Ton Clamping Force), Comprising Of The Following Main Components, Clamping Force: 4.500 kN (≈ 450 Tons). Screw Diameter: 100 mm (Approx.). Downstream & Auxiliary Equipment: Control System: NCIII-S (Digital Control). Technical Data (Approx.): Shot Weight (PS): Up To 1.500 – 1.600 g, Distance Between Tie Bars: Approx. 900 × 900 mm, Opening Stroke: ~800 mm, Mould Height: 350 – 850 mm, Injection Pressure: Up To 1.700 bar, Drive Power: ~75 kW Total Installed, Machine Weight: 26.7 t. Overall Dimensions: L 9.500 × W 2.500 × H 2.500 mm. Power Supply: 3 × 400 V / 50 Hz. - LOT 30

![site]()

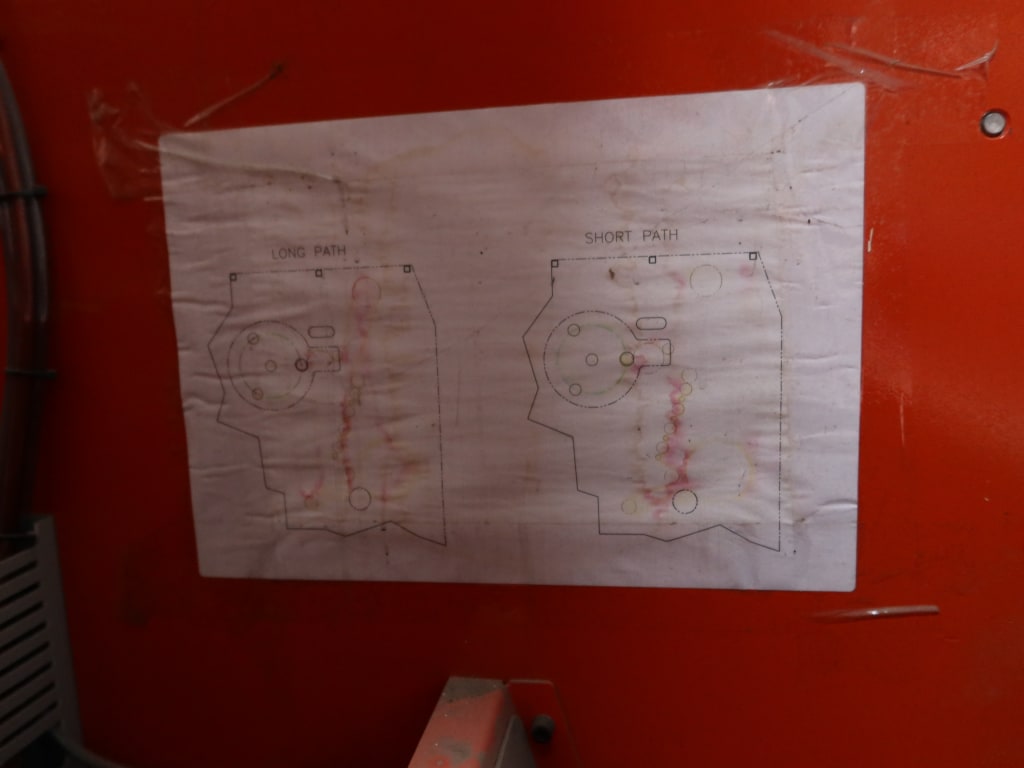

CGA Hollowwrap Type 231-008 Core Cutting & Finishing Machine (2012)

Core Cutting/Finishing Machine (Semi-Automatic), Operating System: Semi-Automatic With Control Panel. Functions: Adjustable Cutting Path (Short / Long), Core Feeding, Precision Cut & Output Tray. Downstream & Auxiliary Equipment: Construction: Heavy-Duty Steel Frame With Integrated Safety Enclosures, Applications: Finishing Of Paper, Cardboard, Or Plastic Cores For Film Rolls, Bags, And Industrial Packaging Applications. Technical Data (Approx.): Overall Dimensions: L 3.500 × W 3.000 × H 2.200 mm. Power Supply: 460 V / 50/60 Hz / 3 Phases, Current: 38 A. - LOT 31

![site]()

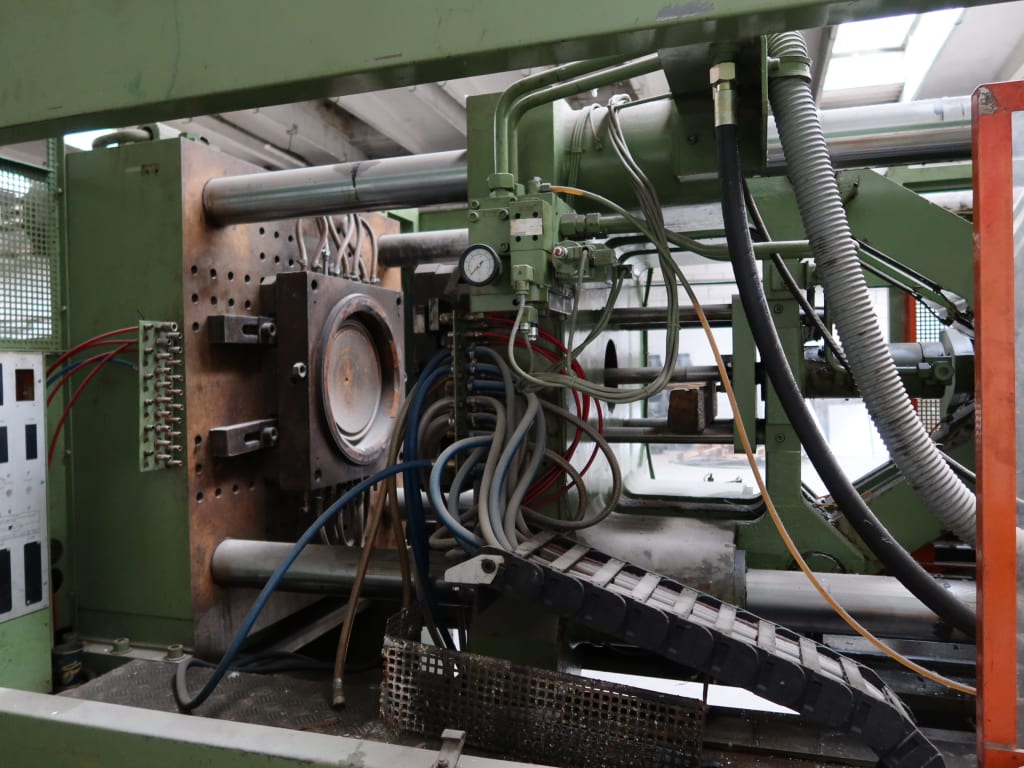

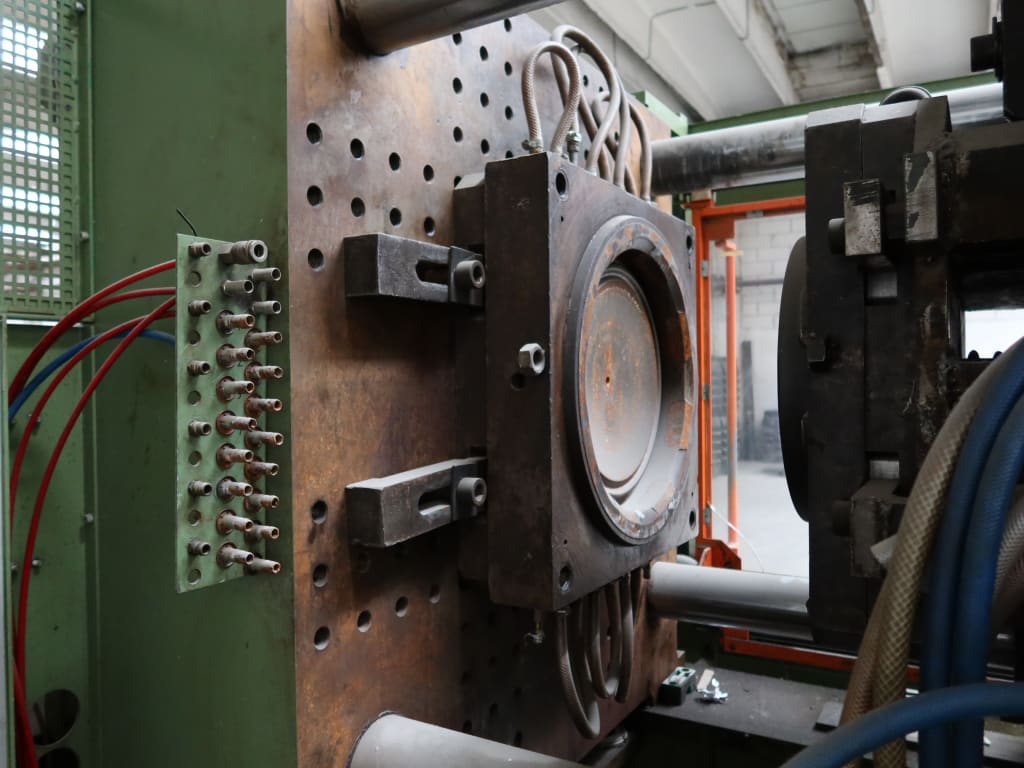

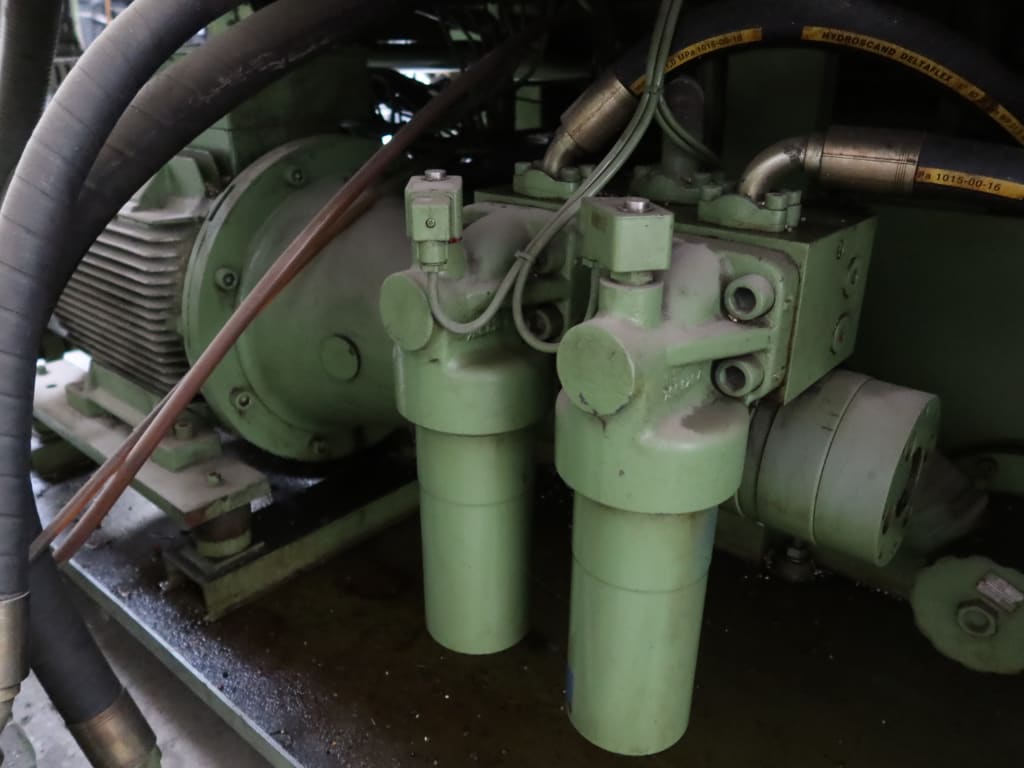

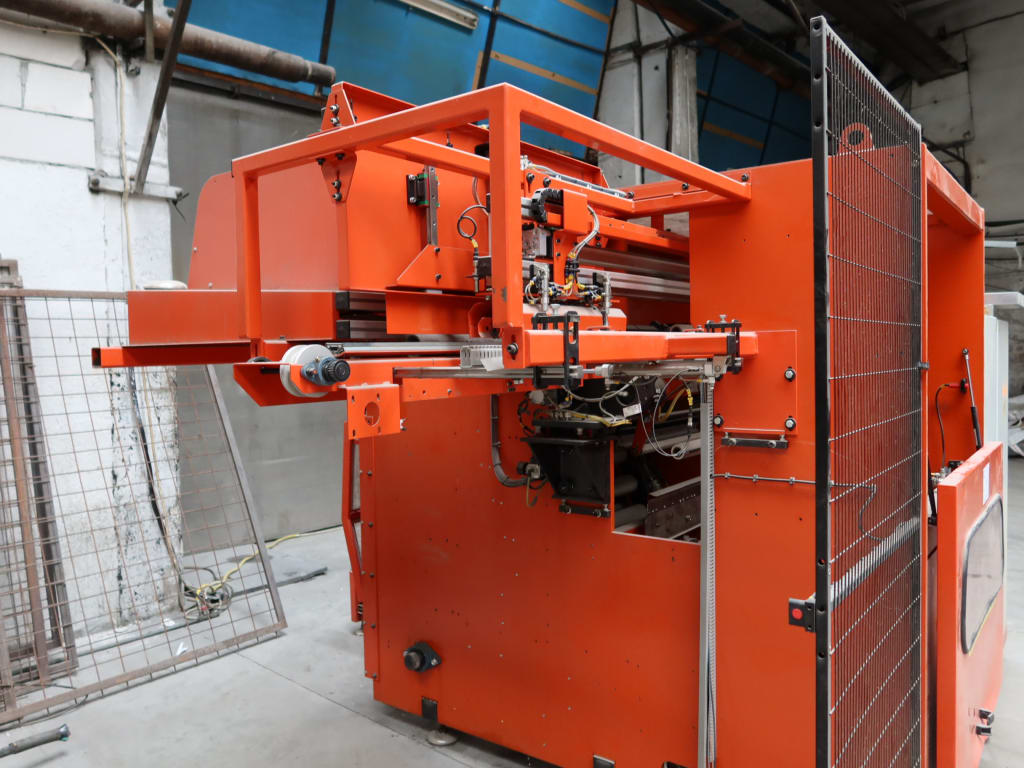

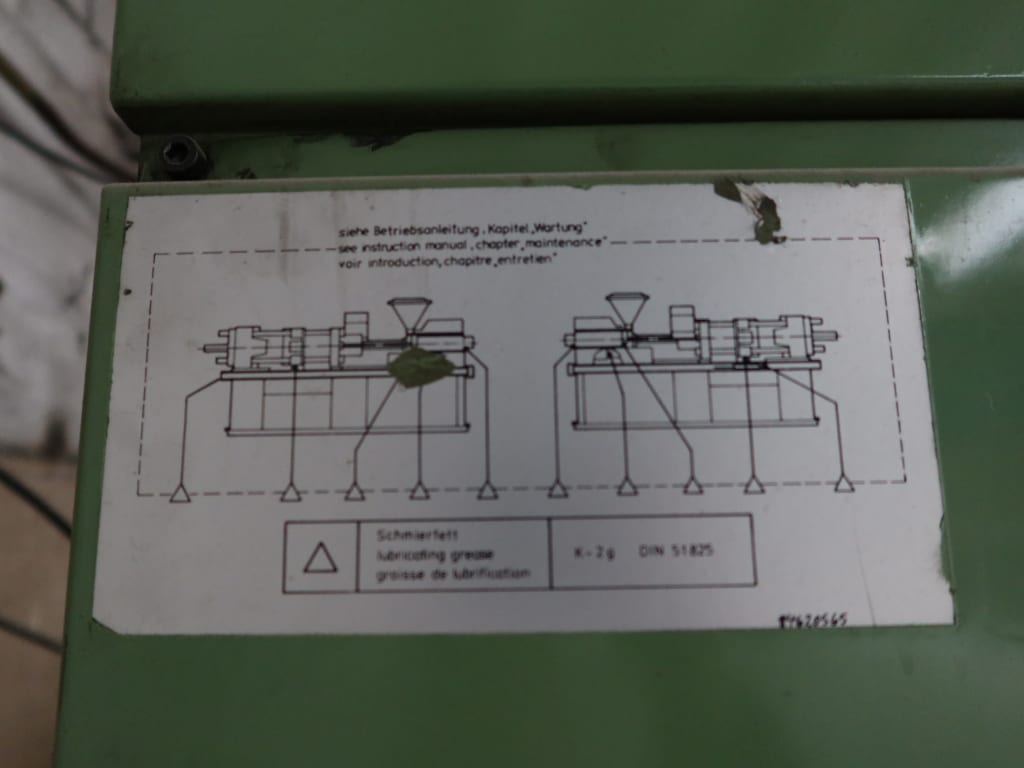

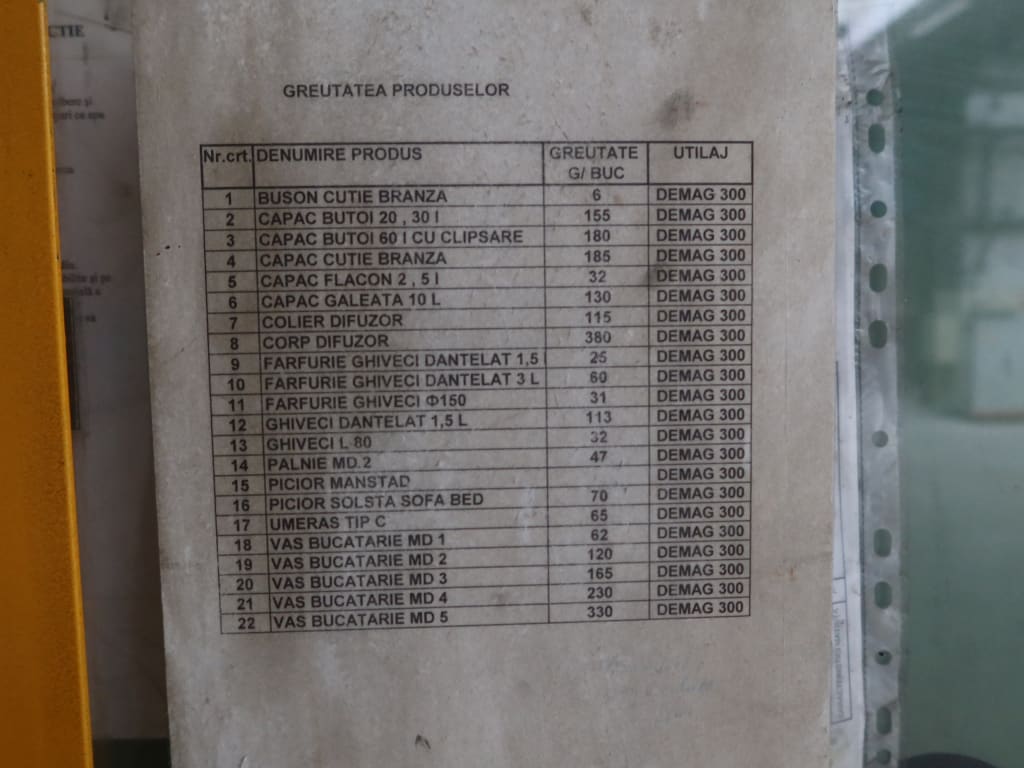

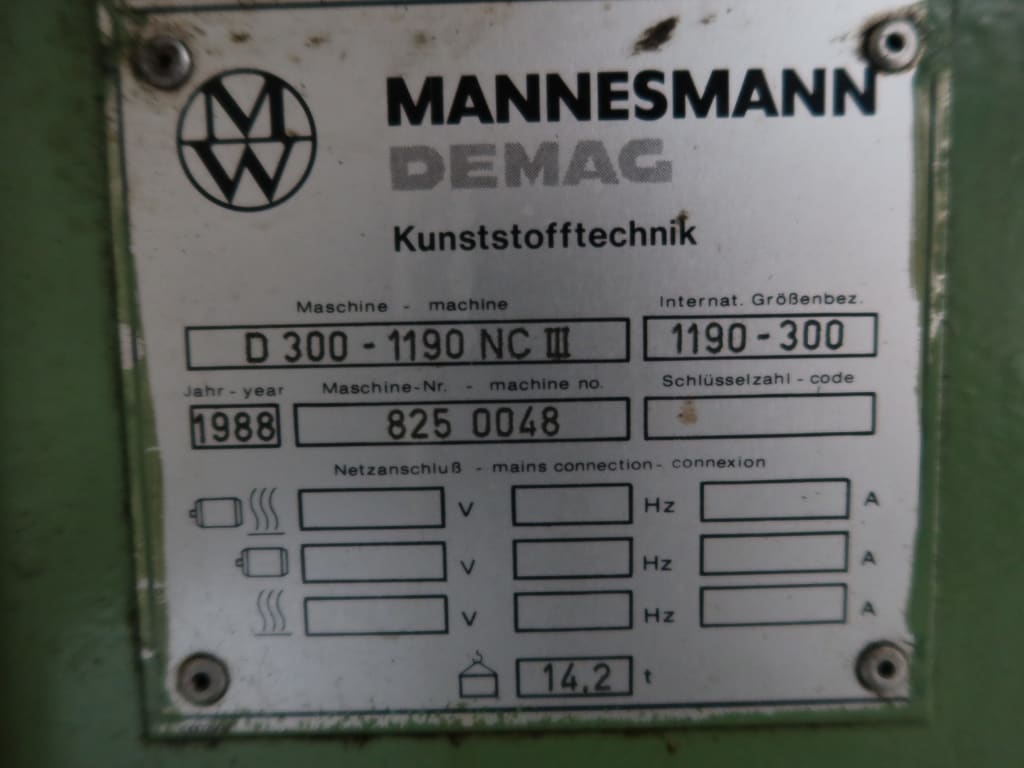

MANNESMANN DEMAG D 300-1190 NCIII Injection Moulding Machine (1988)

Injection Moulding Machine (IMM) (300 Ton Clamping Force), Comprising Of The Following Main Components, Clamping Force: 300 Tons. Injection Capacity: 1.190 cm³. Downstream & Auxiliary Equipment: Control: NCIII (Numerical Control Generation 3), Drive: Hydraulic System With Integrated Safety Guards, Hopper: Top-Mounted Manual Feed. Technical Data (Approx.): Dry Cycle Time: Approx. 2.5 s (Depending On Stroke And Setup), Machine Weight: 14.2 Tons. Overall Dimensions: L 7.500 × W 2.000 × H 2.200 mm. Power Supply: 400 V, 50 Hz. - LOT 32

![site]()

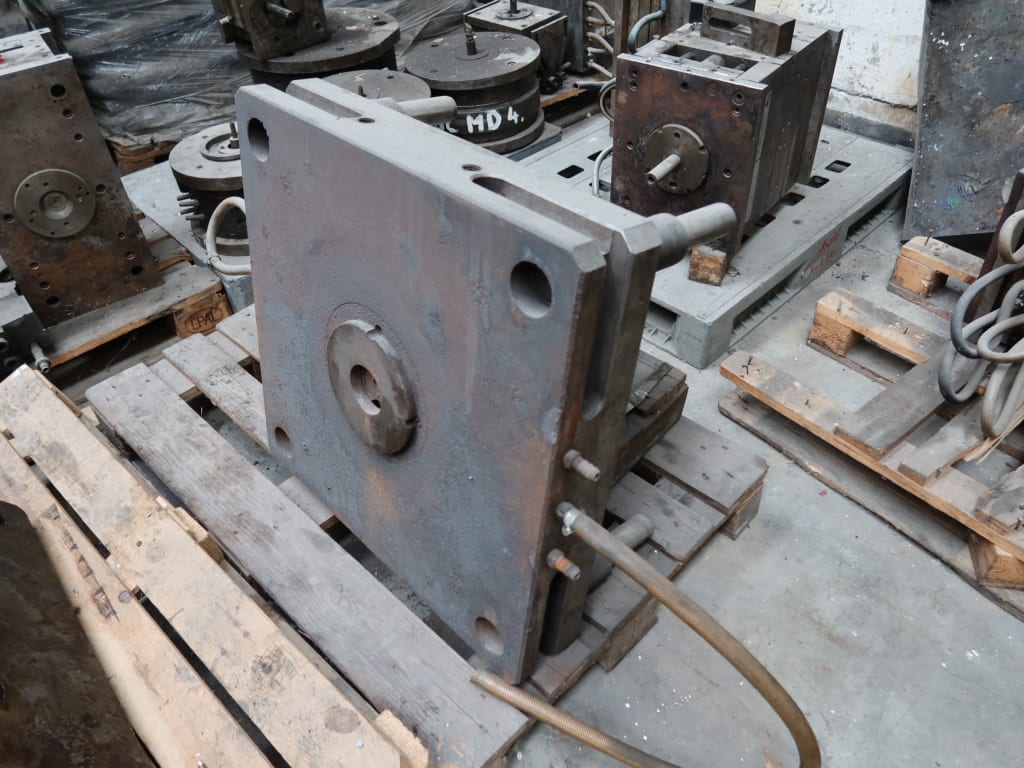

Set of Moulds and Tooling for Injection Moulding Machines

Injection Moulding Tooling / Mould Assemblies Lot, Comprising Of The Following Main Components, Mould Assemblies: Approx. 15–20 Assemblies Of Different Dimensions And Configurations. Core And Cavity Components: Stored On Pallets. Downstream & Auxiliary Equipment: Mould Components: Several Mould Plates, Base Frames, And Inserts, Sleeves: Bronze Cylindrical Mould Sleeves (Pallet Wrapped, Multiple Sizes), Miscellaneous Components: Ejector Systems And Intermediate Plates. - LOT 33

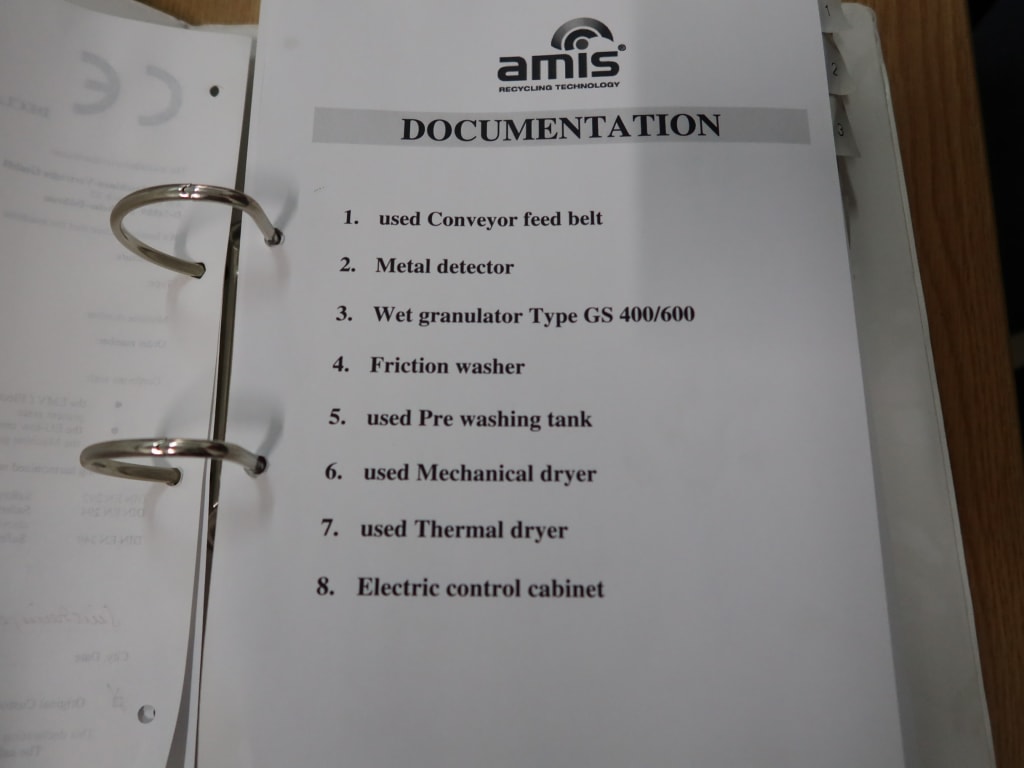

![site]()

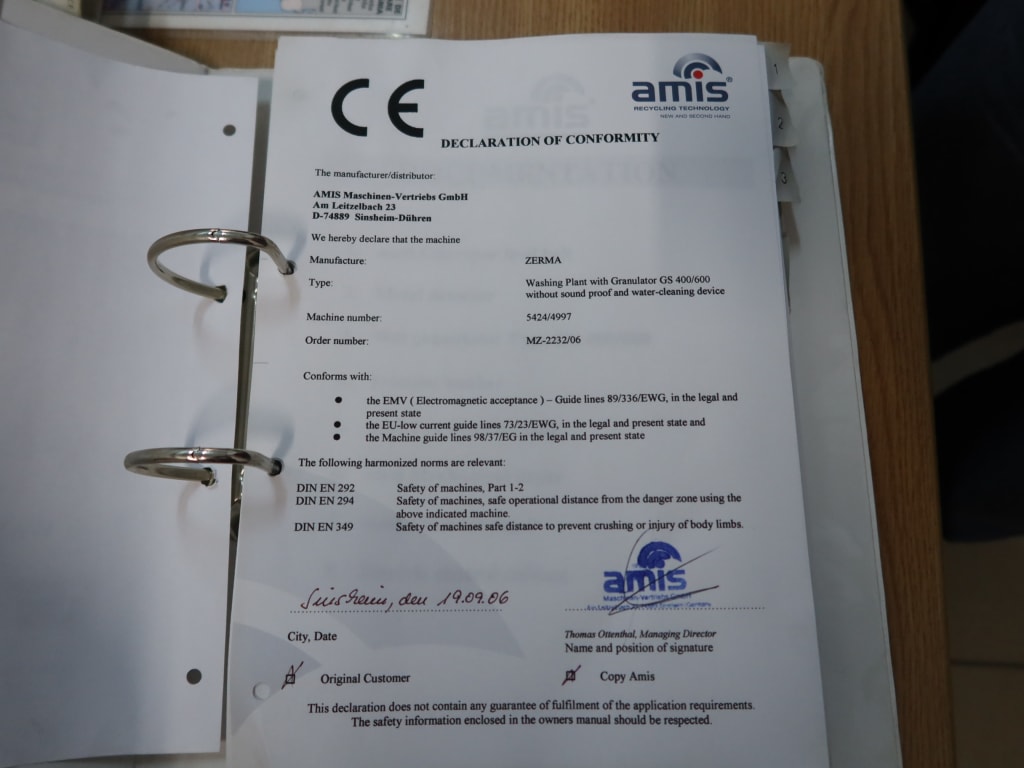

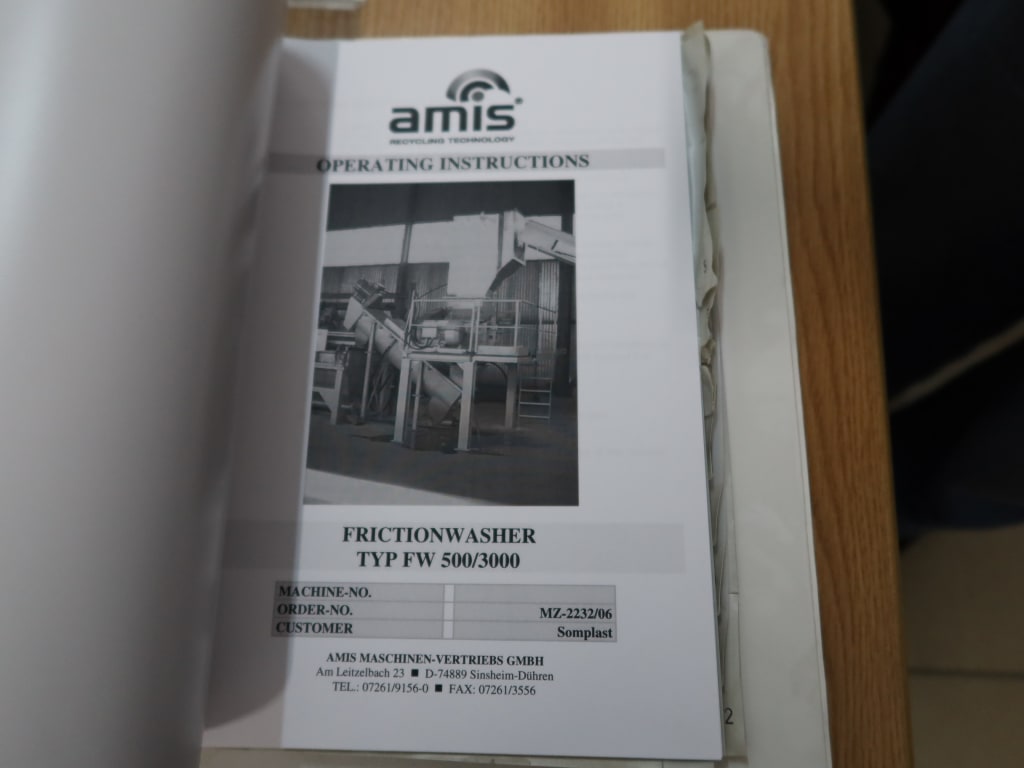

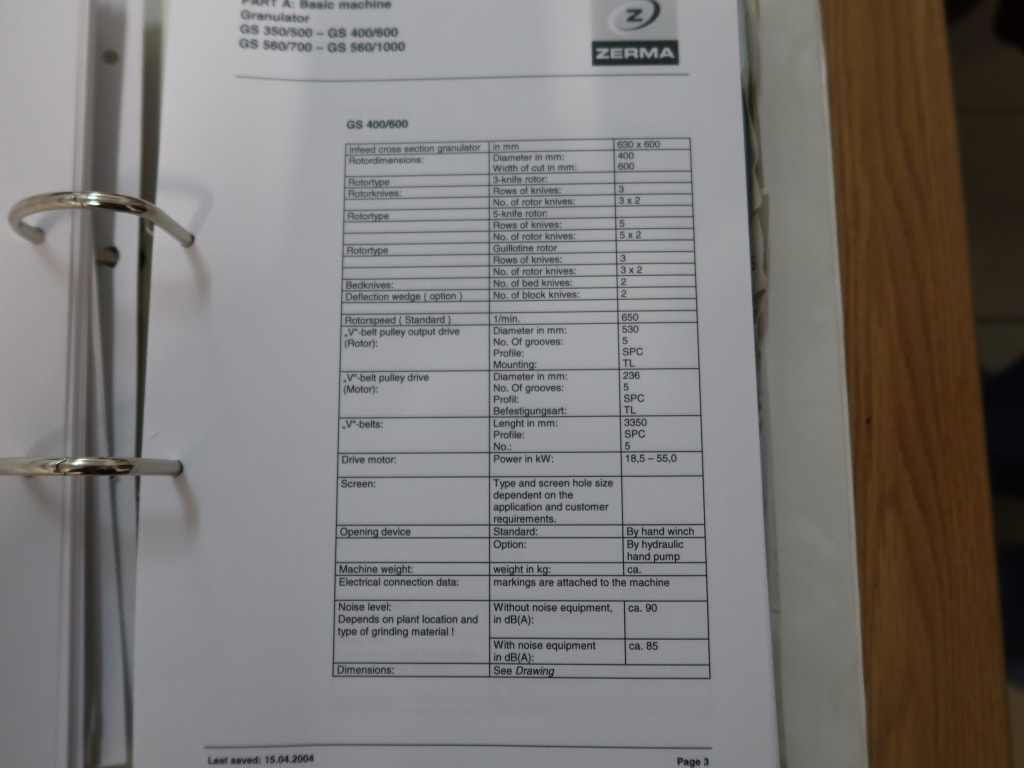

AMIS Machinen-Vertriebs GmbH / Zerma Complete Plastic Film Washing and Granulation Line(2006)

Plastic Washing And Granulating Line (Zerma / Friction Washer), Comprising Of The Following Main Components, Zerma Granulator GS 400/600: Rotor Ø 400 mm × Width 600 mm, Rotor Knives: 3 × 2, Bed Knives: 2, Rotor Speed: 650 rpm. Friction Washer FW 500/3000 (Vertical Type): Height Approx. 3 m, Drive By AMIS Unit, Rotor Cleaning System For Friction Separation. Vertical Dewatering / Squeezing Unit: Height 3 m, Feeding Conveyor Belt: Length 12 m, Width 600 mm, Discharge Height Approx. 5 m, Inclined Screw Conveyor: At 45°, Length Approx. 3.5 m, Transversal Conveyor Belt: Approx. 2.5 m Length, Washing Basin: 4 × 2 m, Sedimentation / Decantation Tanks: Two Units, Cyclone Separator: Ø 800 mm × Height 1.500 mm, Pneumatic Transport Pipe: Approx. 8 m, Discharge Into Big Bag Filling Post, Electrical Control Cabinet: AMIS, For Entire System. Technical Data (Approx.): Drive Power (Granulator): 18.5 – 55 kW; - LOT 34

![site]()

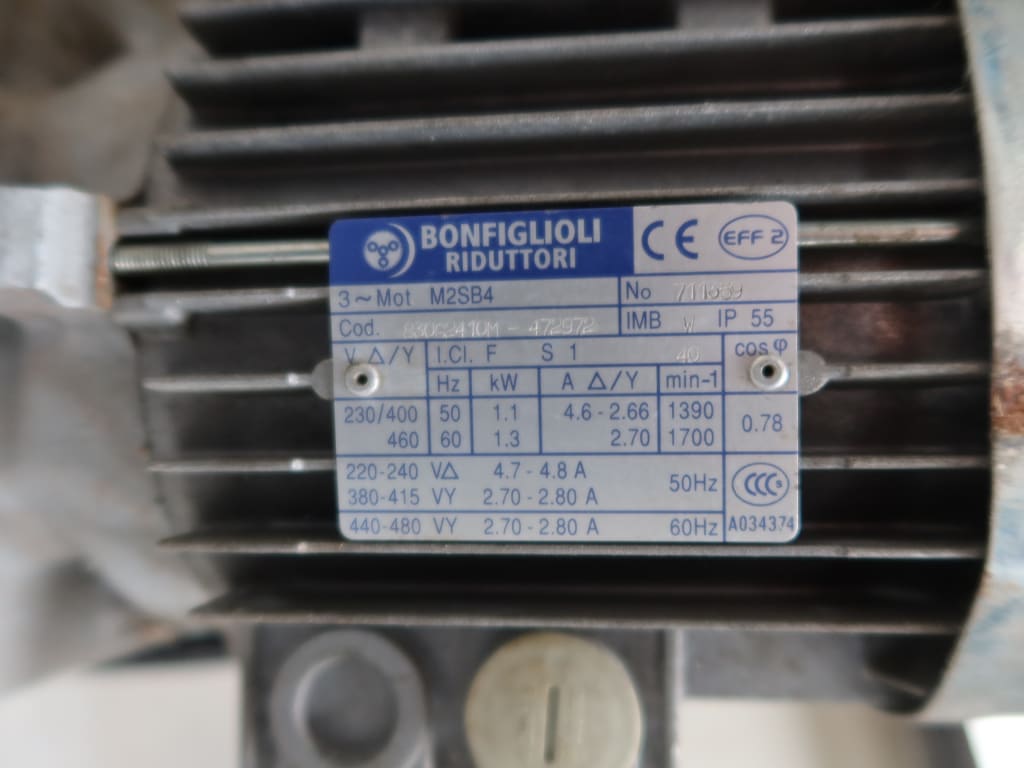

TRIA S.p.A LCE Series Laboratory / Small Plastic Granulator

Slow Speed Granulator / Edge Trimmer Grinder, Comprising Of The Following Main Components, Drive Motor: BONFIGLIOLI M2SB4 – 1.1 kW / 1.390 rpm. Gearbox: BONFIGLIOLI A41 2 UH45 S2, Ratio 53.1:1 (Built 11/2007). Cutting Chamber Width: ~200 mm. Downstream & Auxiliary Equipment: Inlet: Material Inlet With Removable Hopper, Frame: Mounted On Mobile Frame With Wheels, Certification: CE Marked. Technical Data (Approx.): Rotor Speed (Post-Reduction): Approx. 26 rpm, Suitable For: Regrinding Of Small Runners, Sprues, Or Thin Plastic Parts (LDPE, HDPE, PP, PS). Power Supply: 400 V / 3-Phase / 50 Hz. - LOT 35

![site]()

2 Lines Of Plastic Densifiers with Platform and Control Cabinet

Agglomerator / Densifier System (Frictional, 2 Units) No. Of Units: 2. Working Principle: Frictional Densification With Rotating Blades And Water Dosing. Bowl Inner Diameter: 700 mm Each. Bowl Height: 1.000 mm, Discharge: Manual Bottom Outlet, Control System: Independent Electrical Cabinet (Blue), Manual Operation, Construction: Steel Body, Direct Motor Drive. Technical Data (Approx.): Use: Designed For Densification Of LDPE/HDPE Film Flakes Before Pelletizing Or Extrusion, Final Product: Semi-Melted Fluffy Agglomerate With Increased Bulk Density, Total Installed Power: ~30 – 40 kW (Estimated). Overall Dimensions (Including Platform): L 7.000 × W 3.000 × H 2.500 mm. - LOT 36

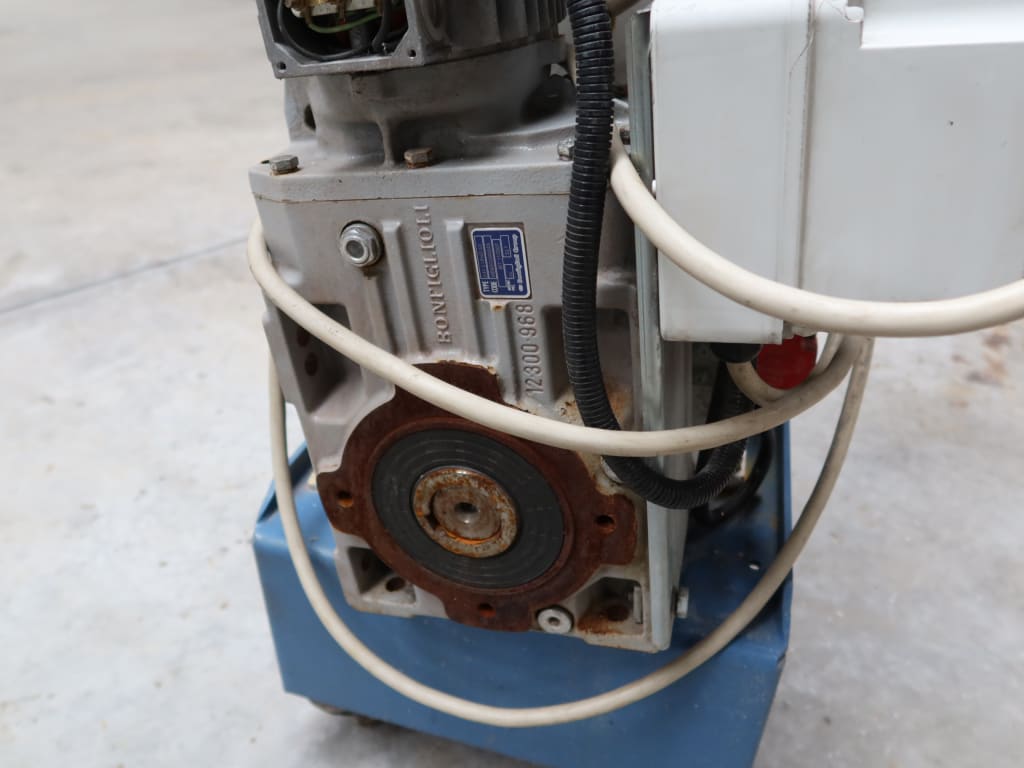

![site]()

TRIA 60-42 XT Plastic Granulator/Grinder

Granulator/Grinder Machine (High Speed Rotor), Comprising Of The Following Main Components, Hopper Opening: 620 × 420 mm. Rotor Diameter: 360 mm. Blades: 3 Rotor + 2 Fixed (Optionally 5 + 2). Motor: 30 kW (Electro Adda EG200L-4). Downstream & Auxiliary Equipment: Feed: Manual Or Conveyor, Discharge: Pneumatic Outlet With Pipe Coupling, Noise Enclosure: Yes. Technical Data (Approx.): Production Rate: 400 – 600 kg/h, Approx. Weight: 1.910 kg, Rotor Speed: ≈ 1.800 rpm. Overall Dimensions: L 1.500 × W 1.200 × H 1.800 mm. Power Supply: 400 V / 690 V, IP55. - LOT 37

![site]()

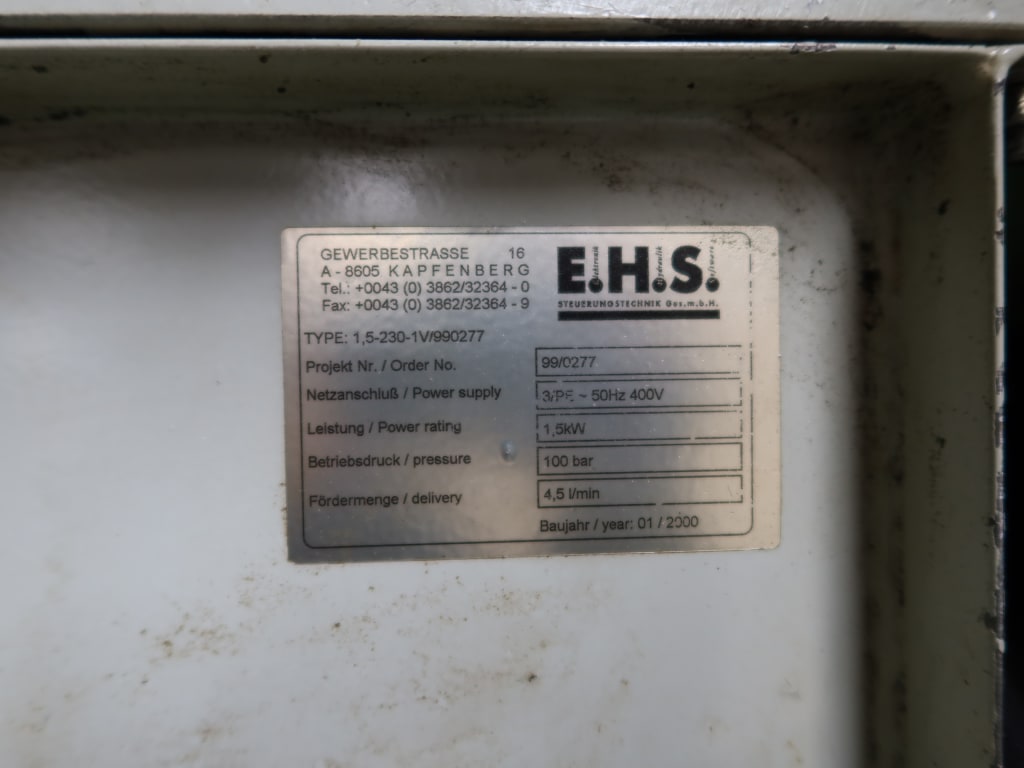

Feed Section with Crusher and Material Hopper (2000)

Pre-Processing / Granulating Unit (Integrated System), Comprising Of The Following Main Components, Compact Granulator/Crusher: With Side Discharge. Drive: Driven By Electric Motor Via Gearbox, Metal Feeding Hopper: With Inclined Auger Conveyor (Approx. 2.500 mm Long) For Loading Plastic Waste Into The Cutting Unit, Control Panel: Local Control Panel With Start/Stop And Emergency Stop Functions. Technical Data (Approx.): Designed For: Processing Plastic Waste From Blow-Moulding Or Injection Operations, Preparing It For Washing Or Regranulation Lines. Overall Footprint: L 3.500 × W 1.200 × H 2.200 mm. - LOT 38

![site]()

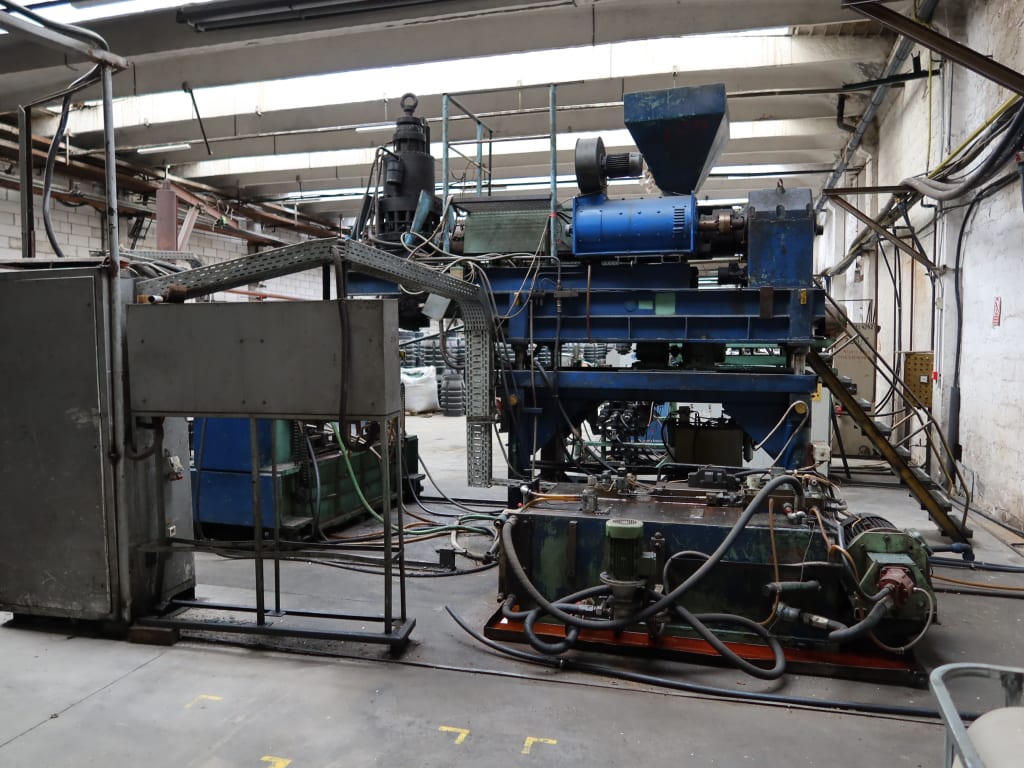

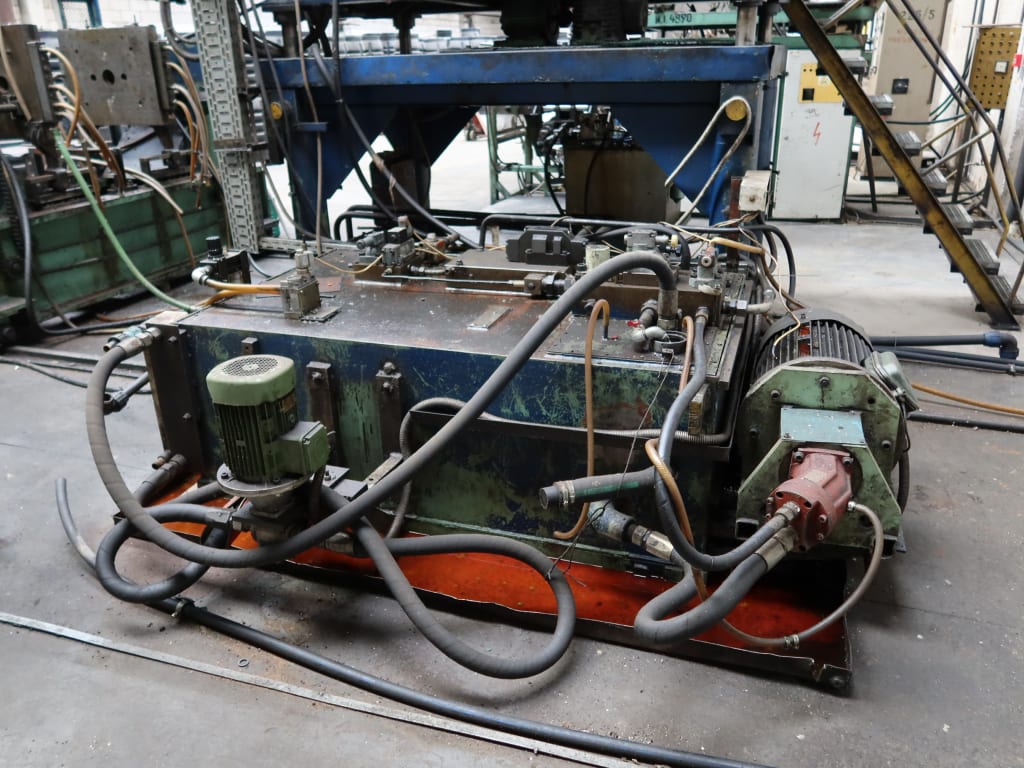

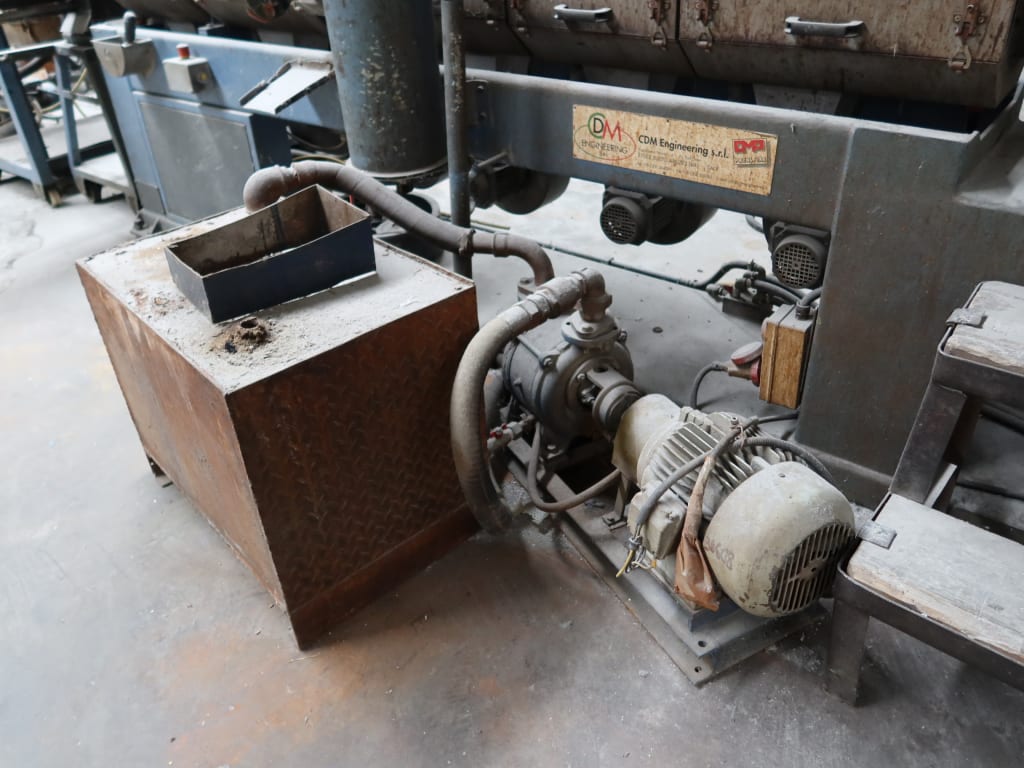

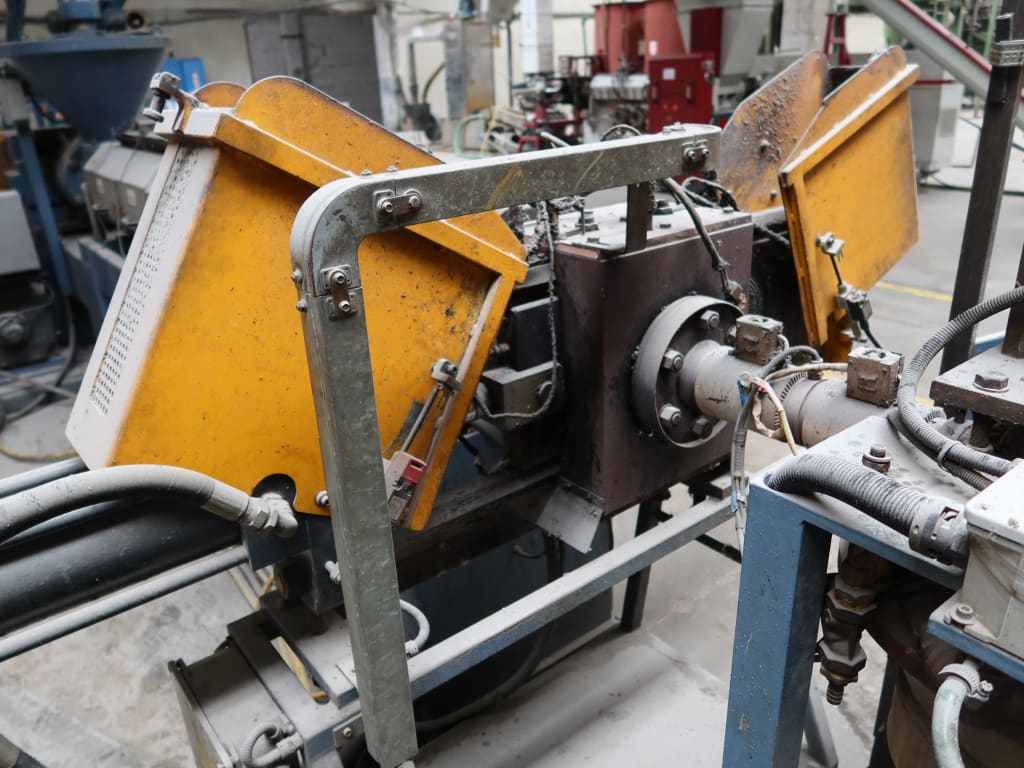

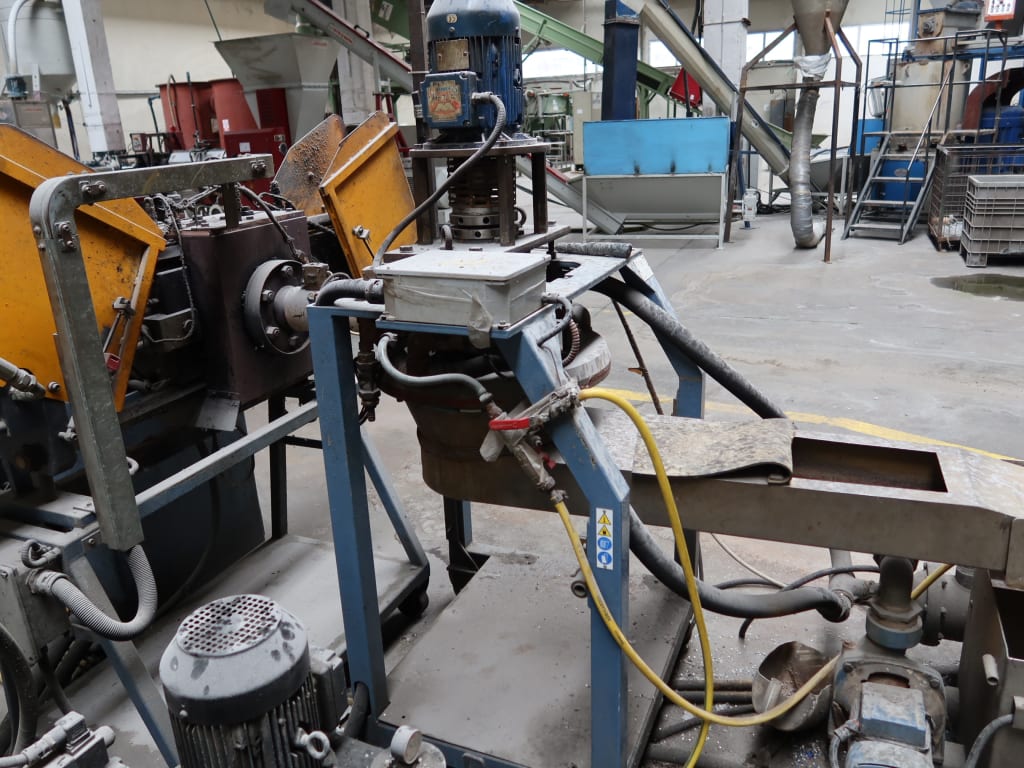

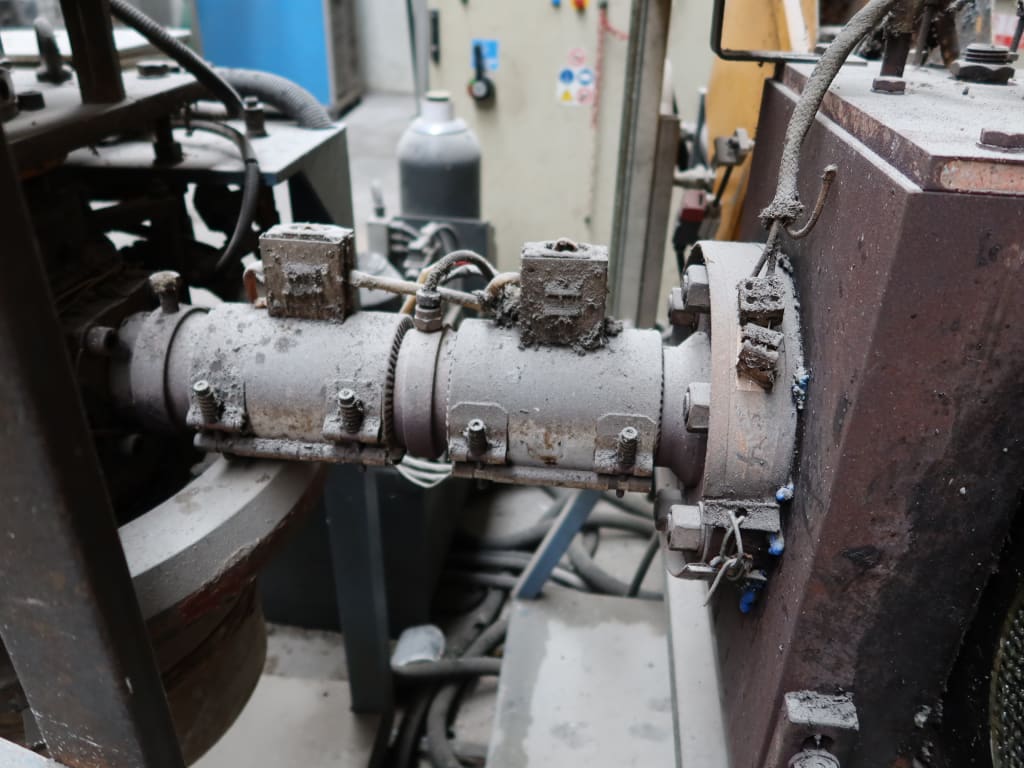

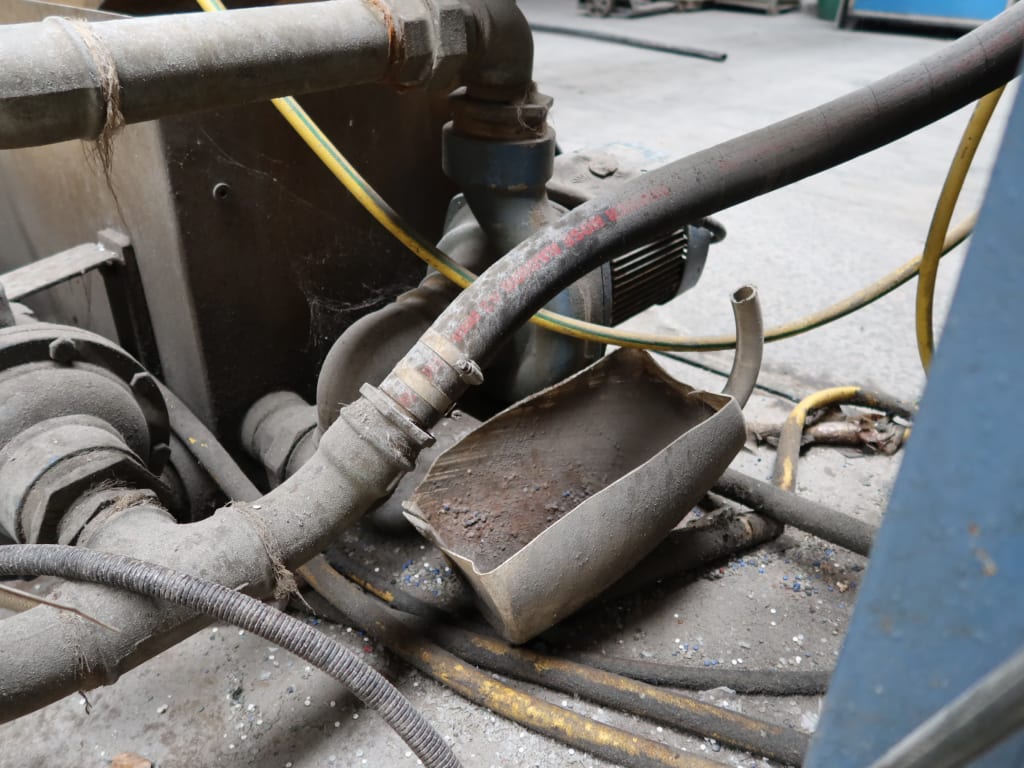

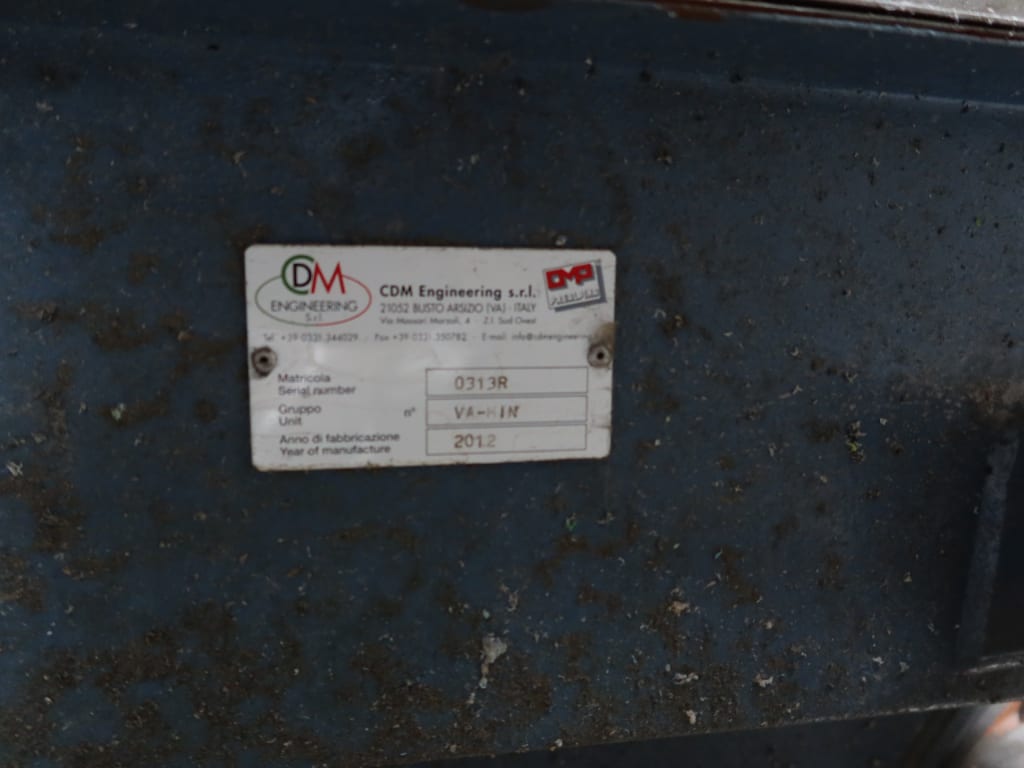

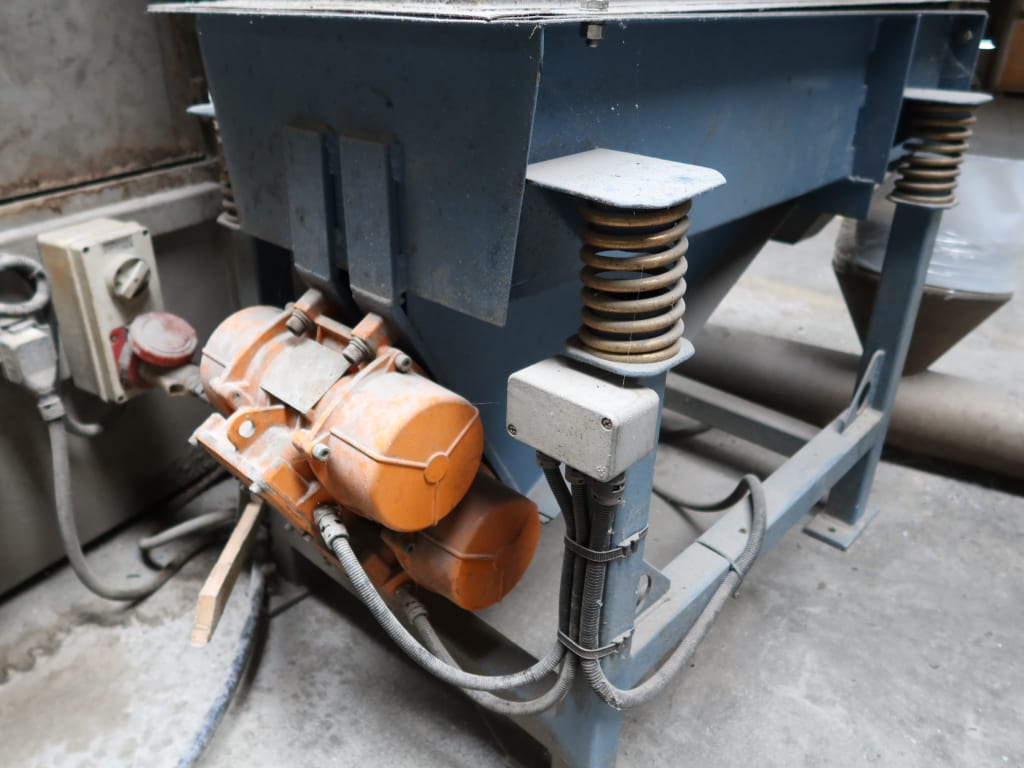

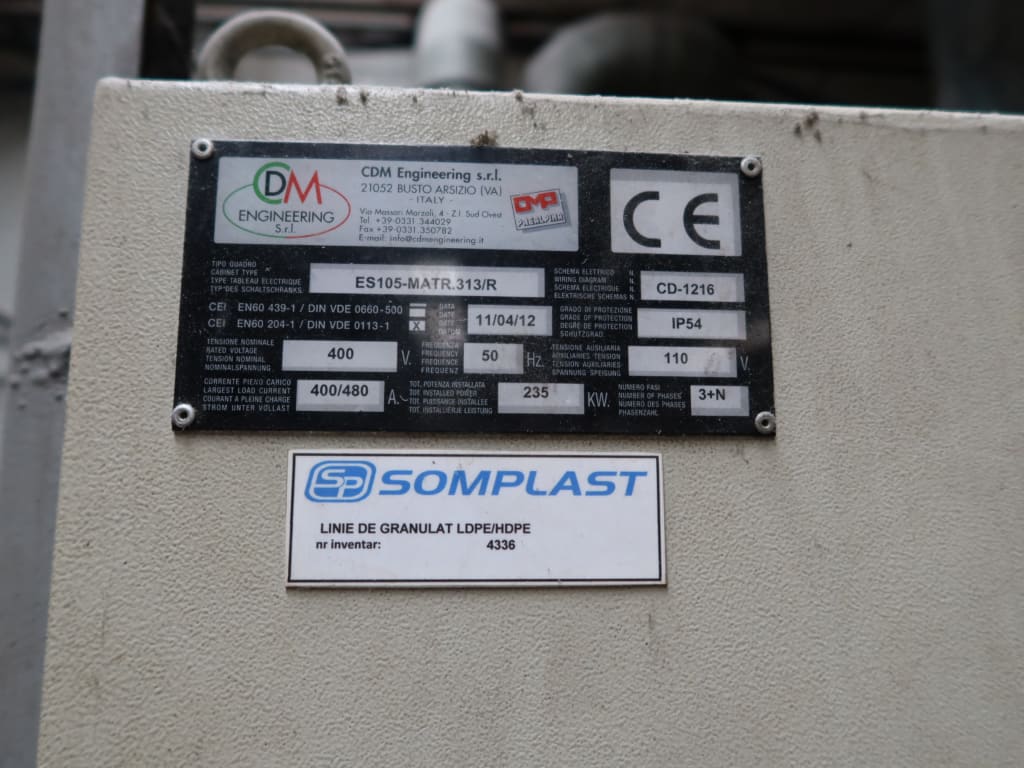

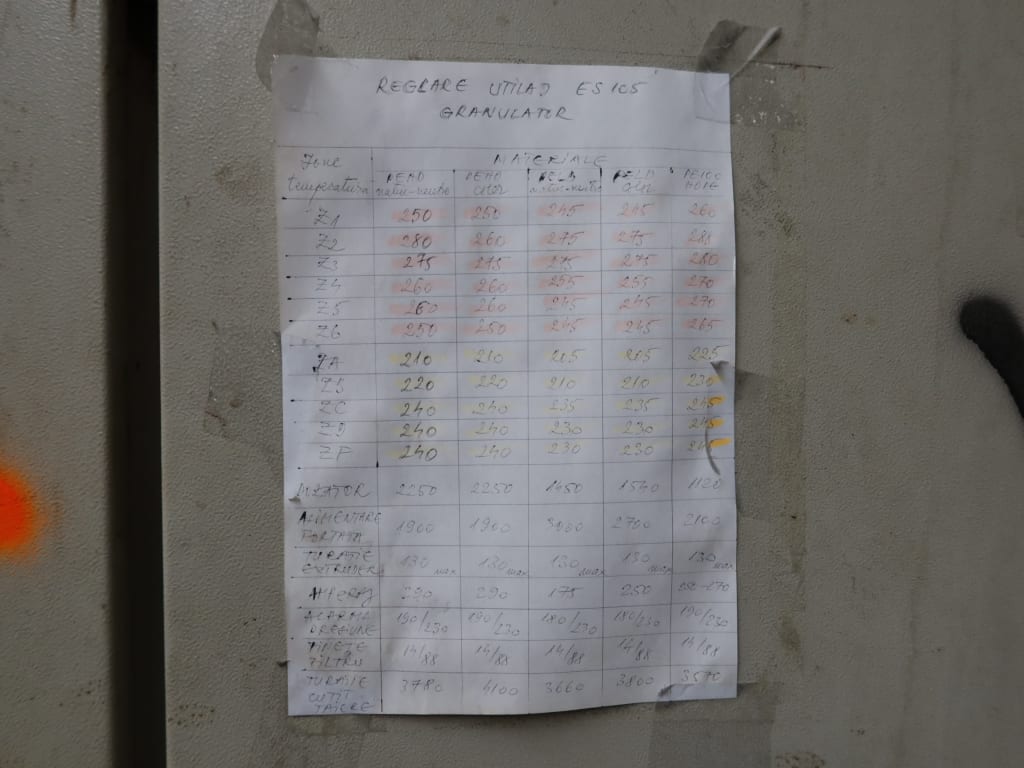

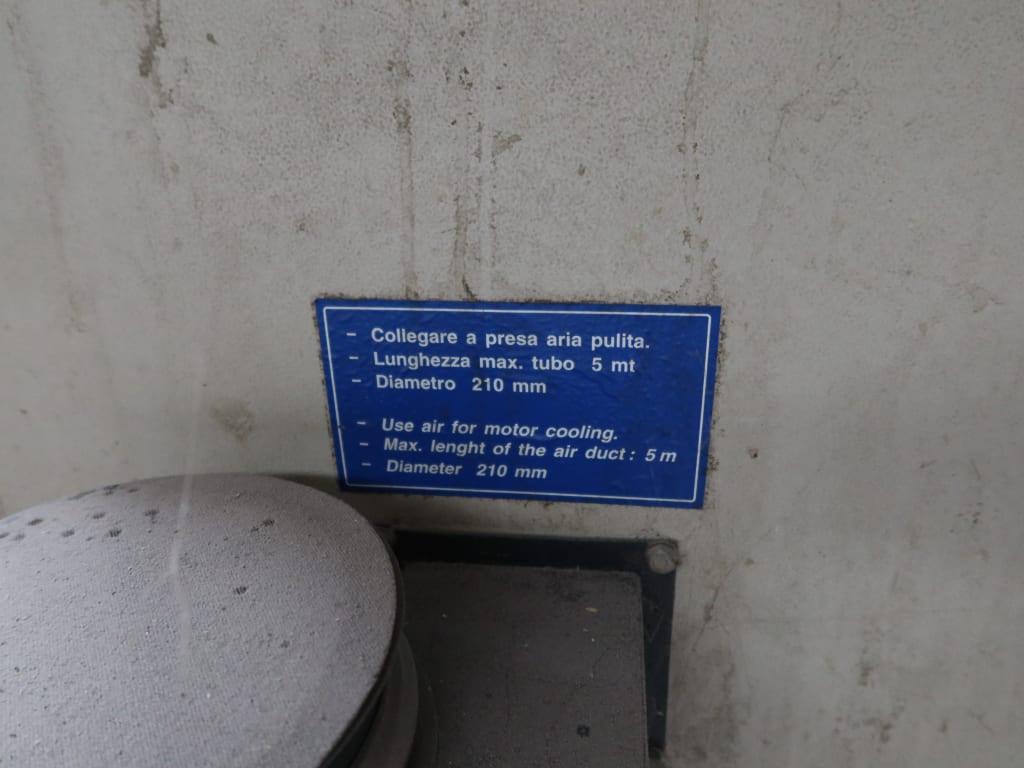

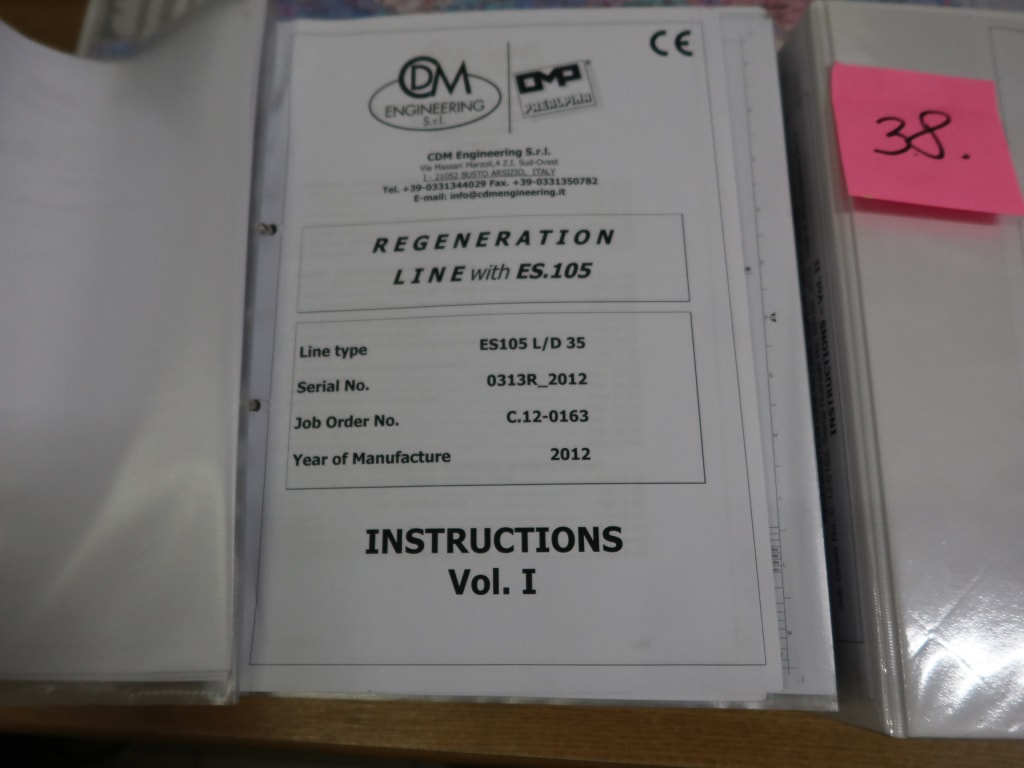

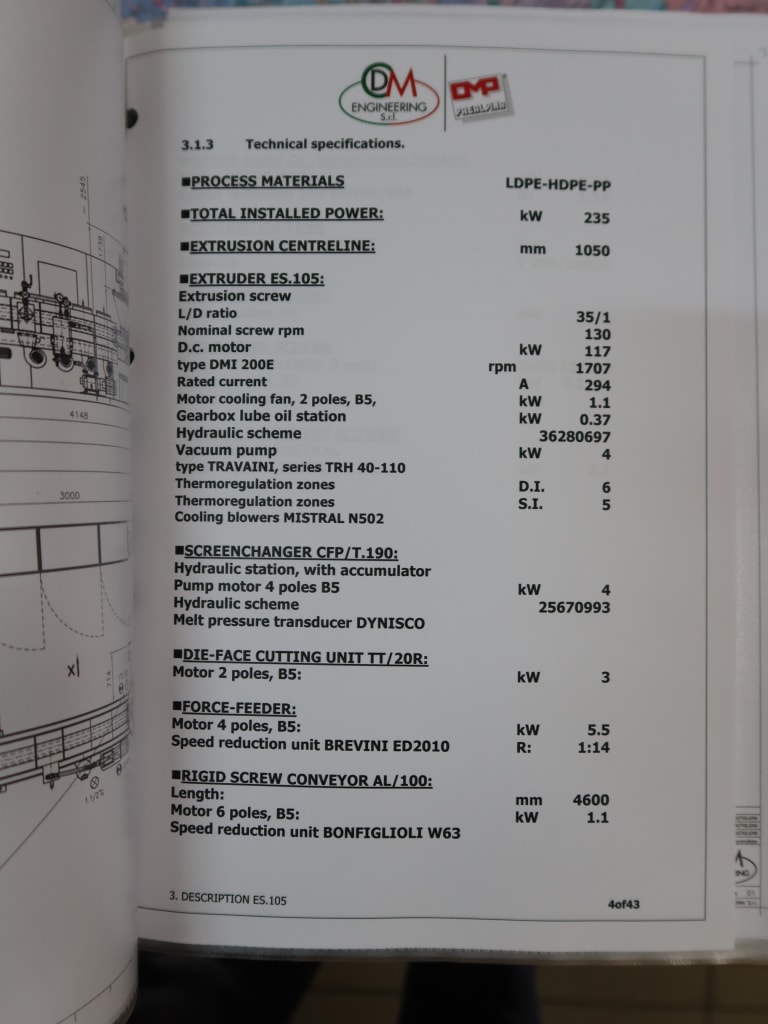

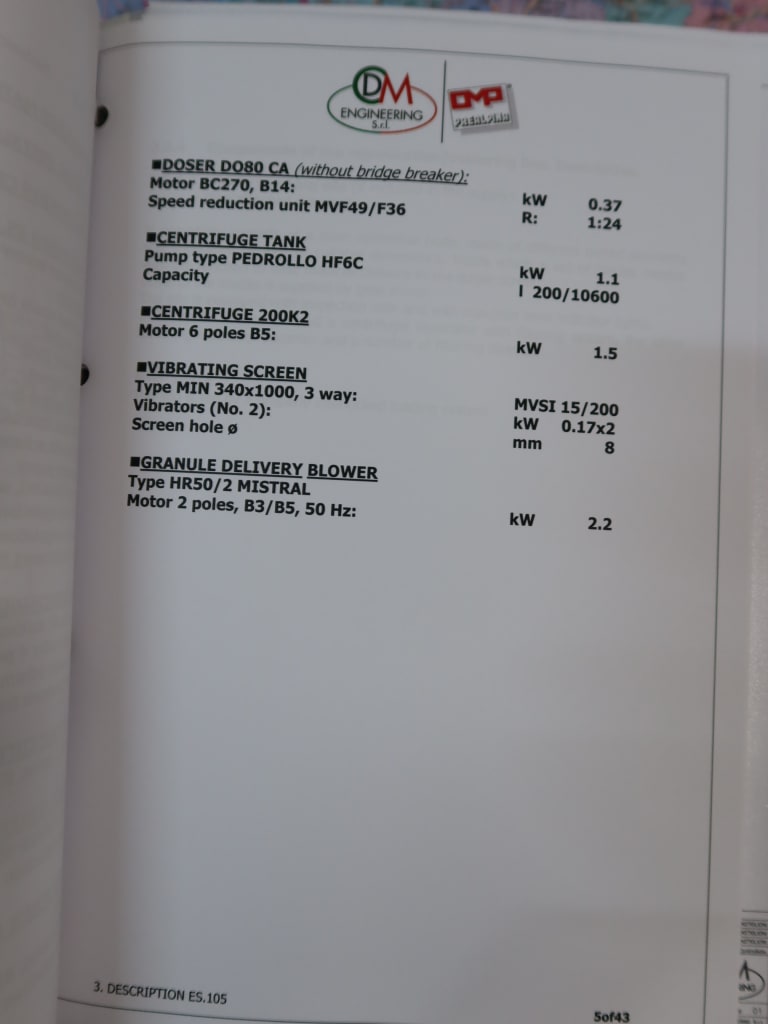

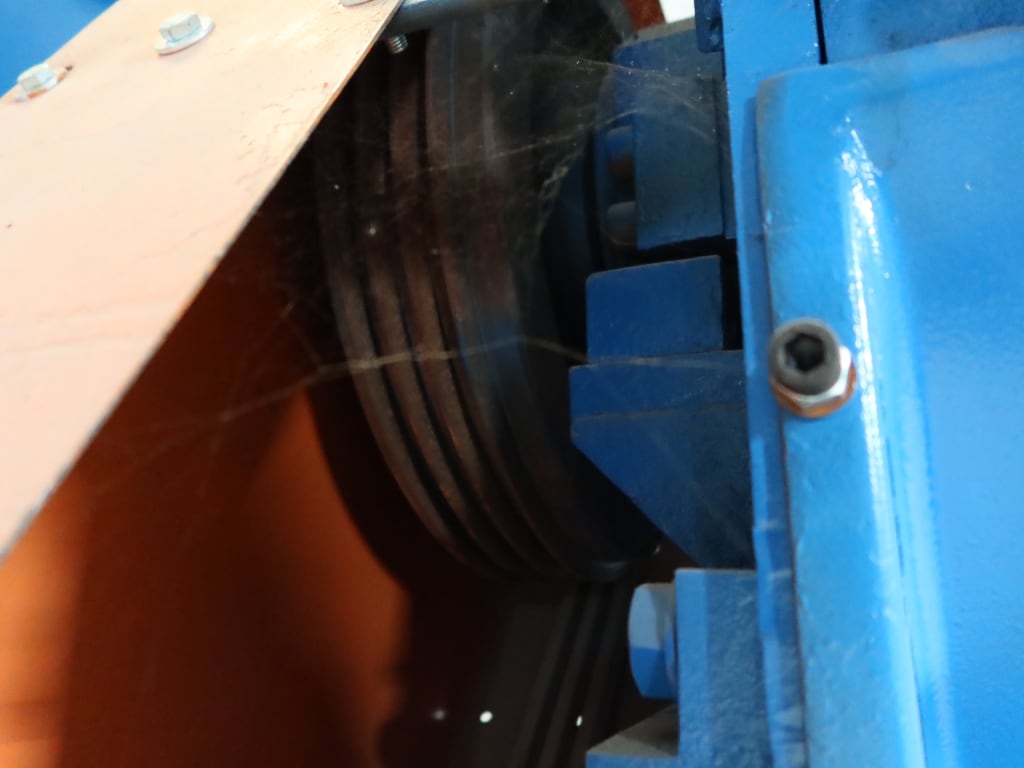

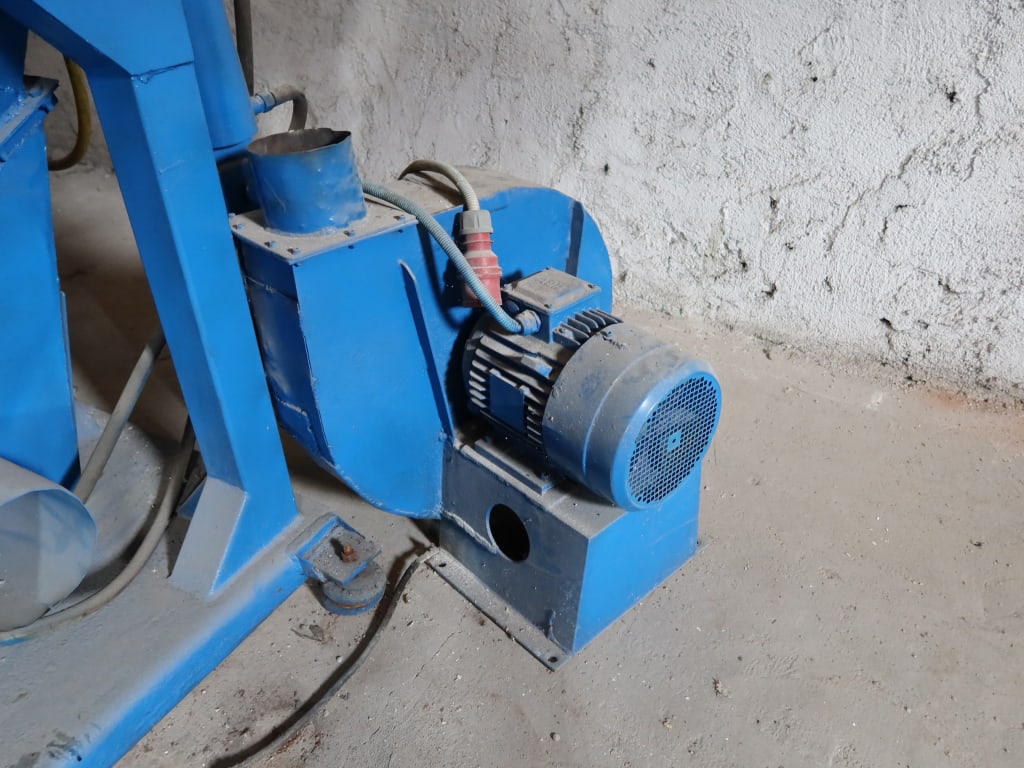

CDM Engineering ES-105 Plastic Pelletizing Line (2012)

Plastic Compounding / Pelletizing Line (Single Screw, Degassing), Comprising Of The Following Main Components, Single-Screw Extruder: Screw Ø105 mm, With Degassing And Screen Changer. Granulation Head: Diameter Approx. 150–180 mm (Based On Output Class), Feeding Unit: Hopper (Approx. 900 × 900 mm) Equipped With Magnetic Separator, Inclined Screw Conveyor: ~3.500 mm, For Material Transport To Extruder, Cooling Bath And Vibrating Drying Unit, Vibrating Sieve Table: For Pellet Separation, Electrical Control Cabinet: Dimensions Approx. L 3.500 × W 800 × H 2.200 mm. Technical Data (Approx.): Output: Uniform Plastic Granules Ø ≈ 5 mm. Overall Footprint: L 12.000 × W 3.500 × H 4.000 mm. - LOT 40

![site]()

2 Eurochiller Industrial Water Chillers

Model EF CE35 (2001) Power supply 400 V / 50 Hz, power 15 kW, cooling capacity 41 kW (water 15°C / air 25°C), protection IP54. Model EF AE70 (2000) Power supply 380 V / 50 Hz, power 30.7 kW, cooling capacity 81.6 kW (water 15°C / air 25°C), protection IP54. - LOT 41

![site]()

Inclined Belt Conveyor

Technical details: Length approx. 7 m, belt width 600 mm, mounted on steel frame with wheels for mobility, belt type flat PVC or rubberized fabric; Function: Transfers cleaned or processed plastic flakes or granules to the next processing unit (e.g., extruder or agglomerator). - LOT 42

![site]()

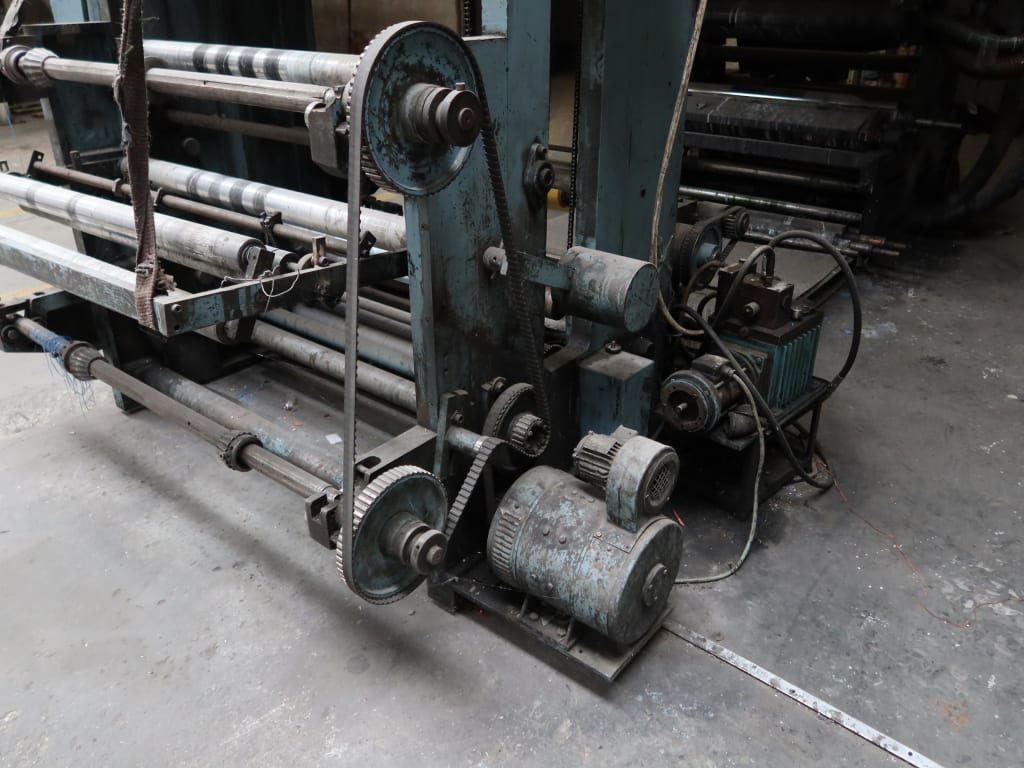

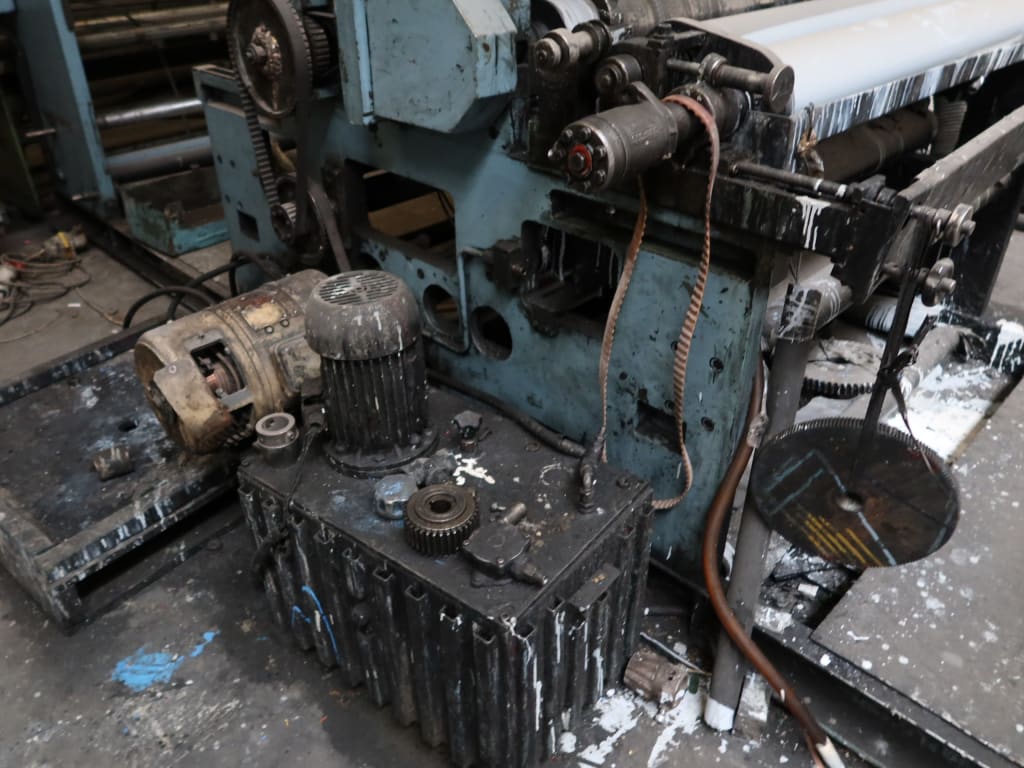

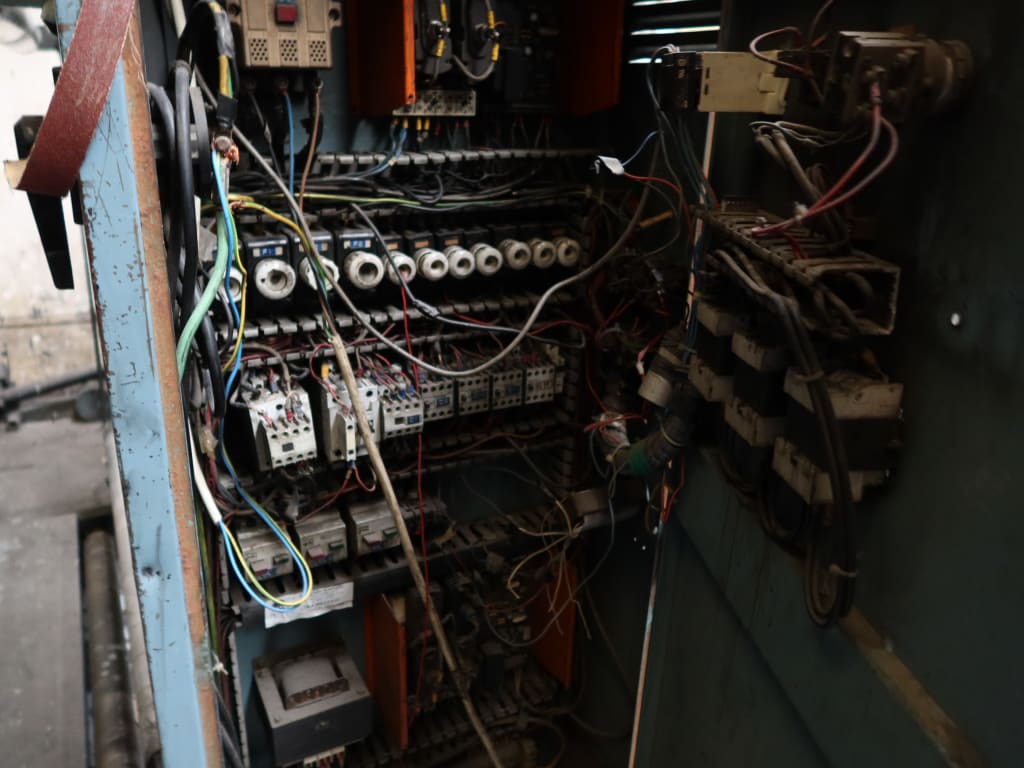

Plastic Granulator/Crusher

Granulator / Crusher (Belt-Driven Rotor), Comprising Of The Following Main Components, Rotor Type: Open, Multi-Knife Configuration (Exact Number Not Visible). Feed Opening: 500 × 500 mm, Construction: Steel Frame With Belt-Driven Rotor, Side-Mounted Motor And Safety Covers. Technical Data (Approx.): Drive: Electric Motor, Approx. 18 – 22 kW, Function: Designed To Granulate And Prepare Plastic Material For Washing Or Extrusion, Suitable For: HDPE, LDPE, And PP Regrind. Overall Dimensions: L 4.000 × W 1.500 × H 2.000 mm. - LOT 43

![site]()

Plastic Washing and Separation System “David Harrison / PolyWash

Plastic Washing / Pre-Treatment System (High-Efficiency Mechanical Washing), Comprising Of The Following Main Components, Main Washing Tank: With Paddle Shaft And Agitation System (Visible Paddles For Efficient Friction Cleaning). Rotating Friction Washer / Separation Tank: For Removal Of Dirt, Labels, And Lighter Contaminants, Inclined Screw Conveyor: For Continuous Discharge And Transfer Of Washed Material, Drive Systems: Motors And Gearboxes Installed On Each Section, Drive Systems Complete, Construction: Painted Steel, Reinforced Frame. Technical Data (Approx.): Function: The System Is Intended For Use In Plastic Film And Rigid Plastic Recycling Lines, Providing High-Efficiency Mechanical Washing Prior To Drying And Extrusion, Secondary Dimensions: Approx. 5.500 × 2.000 × 3.000 mm (Secondary Unit). Overall Dimensions: L 7.000 × W 2.000 × H 2.500 mm. - LOT 44

![site]()

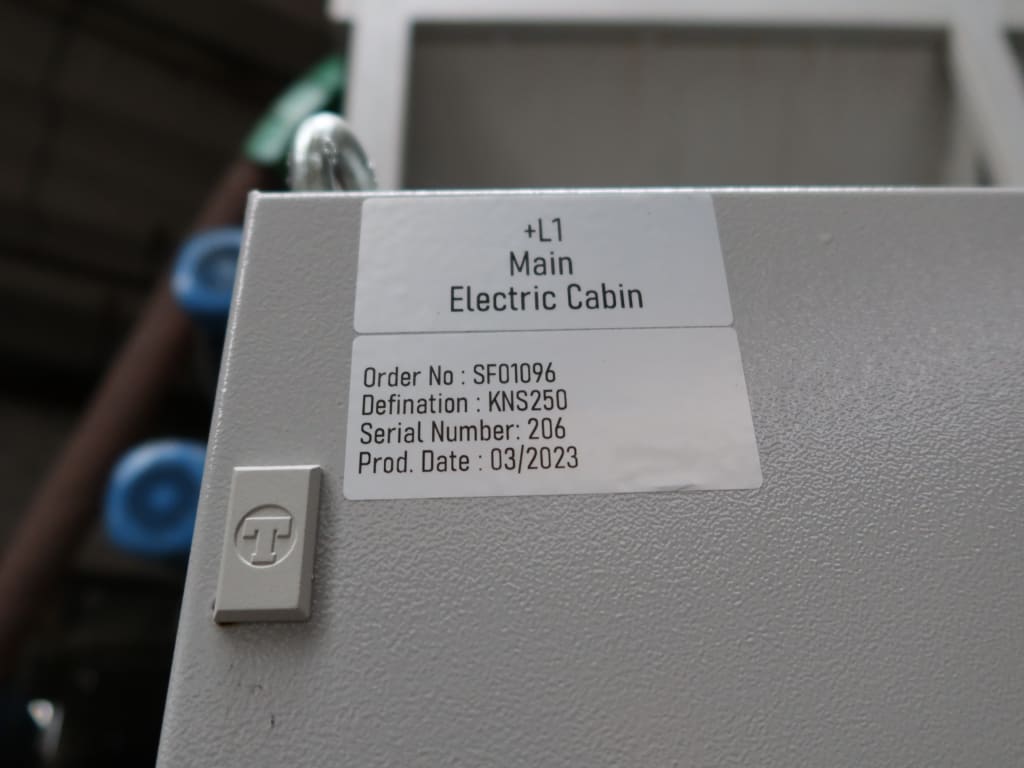

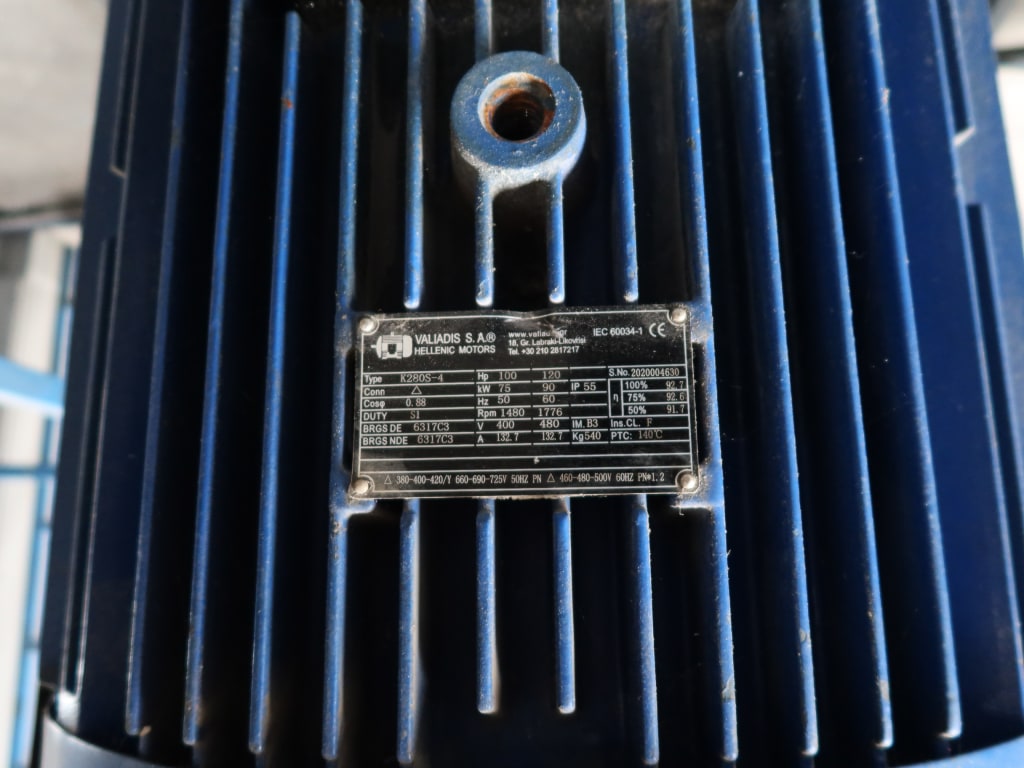

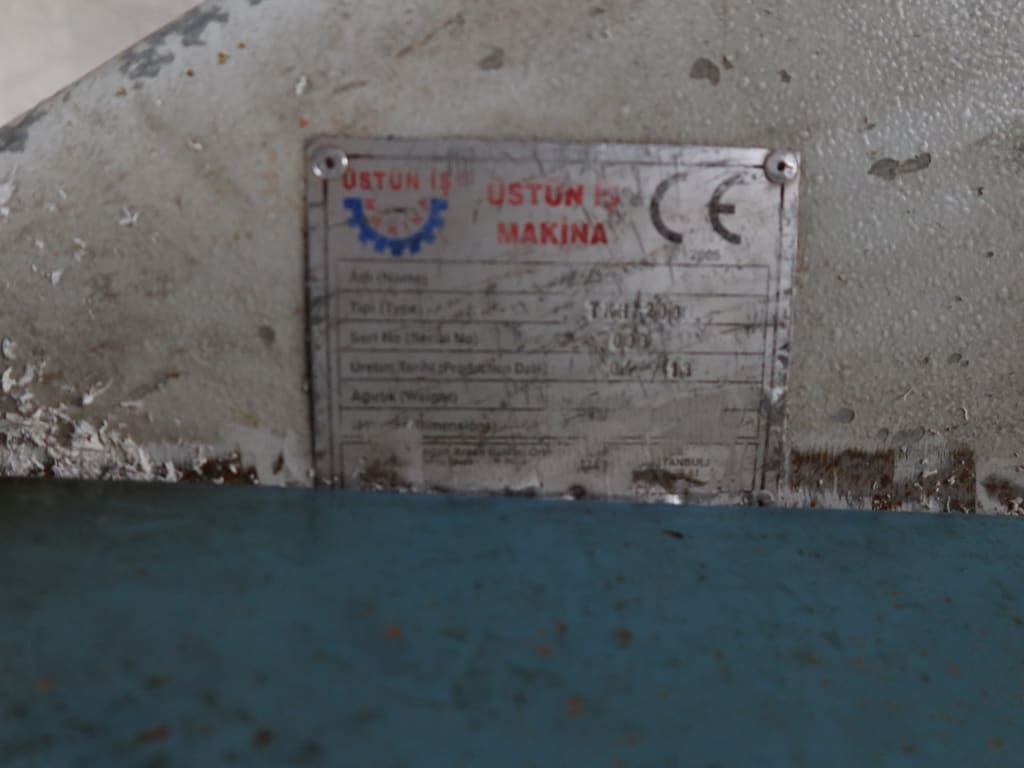

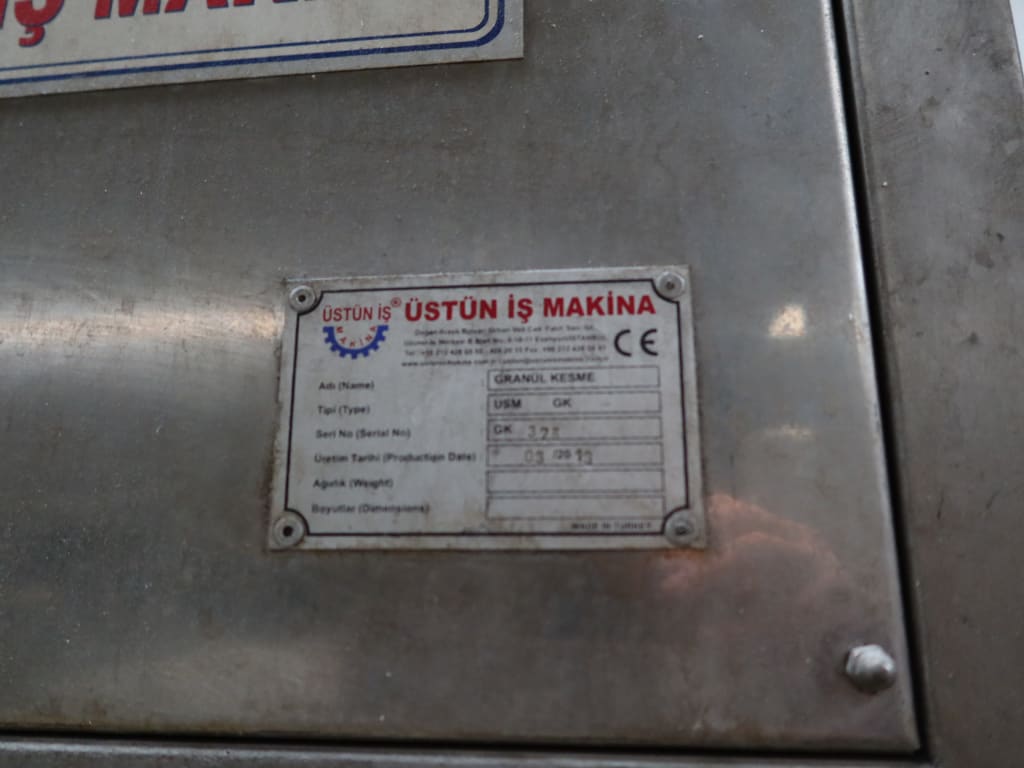

UstunIsMakina USM KNS300 Plastic Dewatering/Squeezing Line with Bexmac Drive and Electrical Cabinet (2023)

Squeezing / Dewatering Press (Conical Screw), Comprising Of The Following Main Components, Press Body: UstunIsMakina USM KNS300 With Conical Squeezing Screw. Drive Motor: High-Torque BEXMAC Assembly. Gearbox: Yilmaz Reduktor Type LTE0823.0XER, Ratio 28.64:1, Electric Control Cabinet: Main Electric Cabin Model KNS250 (Order No. SF01096, Production Date 03/2023), Cooling: Cooling Fan And Pneumatic Discharge System For Material Outlet. Technical Data (Approx.): Function: Designed For Mechanical Dewatering And Densification Of Washed Film Flakes Or Regrind, Before Extrusion Or Pelletizing. Reduces Moisture Content And Increases Bulk Density For Easier Feeding, Power: 75 kW Main Motor, Screw Speed: 49 rpm, Oil Type: VG320 (52 L). Overall Dimensions: L 4.000 × W 1.200 × H 1.700 mm. Power Supply: 400 V / 50 Hz. - LOT 45

![site]()

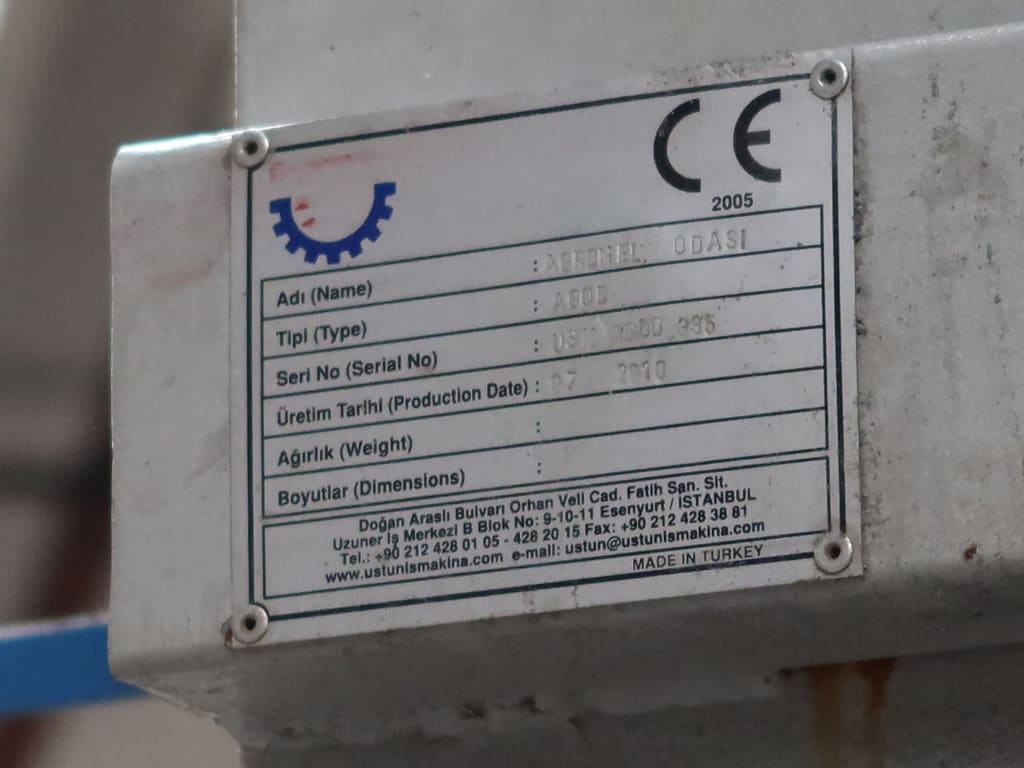

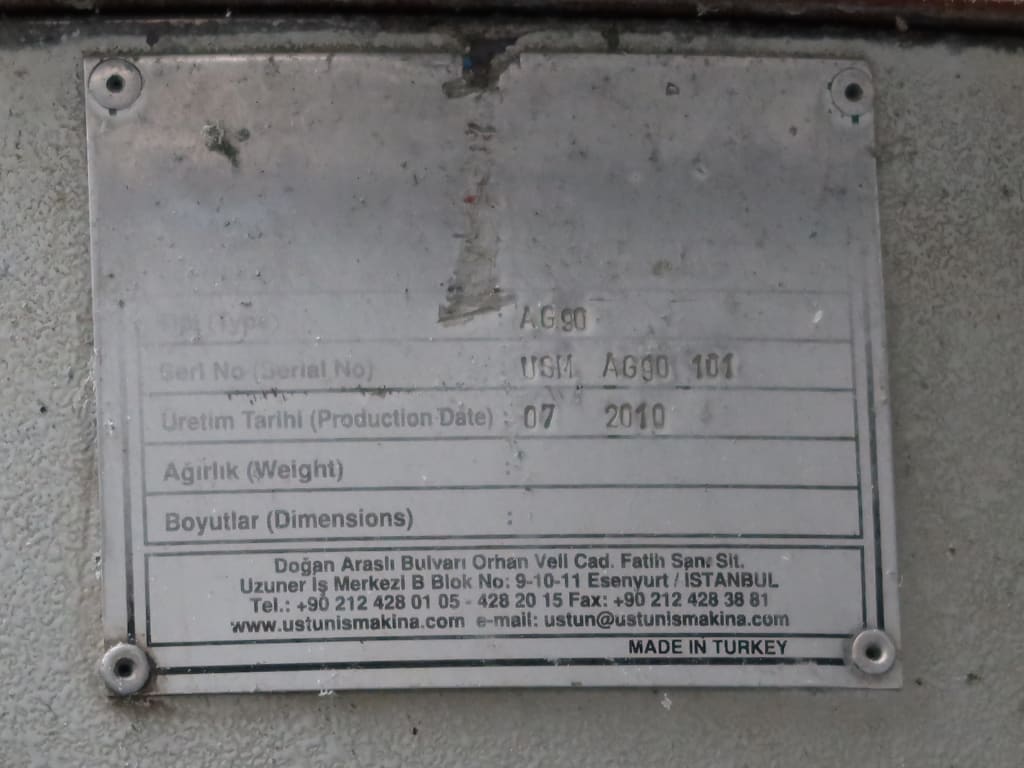

Ustun Is Makina Complete Agglomeration and Drying Unit (2010)

Agglomeration / Densification System (USM AG90, 90 kW Main Drive), Comprising Of The Following Main Components, Agglomerator: Model USM AG90 101, Year 2010, Chamber Ø ≈ 1.000 mm, Heavy-Duty Friction Compactor Type. Feeding Silo: Rectangular Steel Silo, Approx. L 3.000 × W 2.200 × H 2.500 mm, Fitted With Twin Horizontal Screw Extractors And Geared Motors. Downstream & Auxiliary Equipment: Transfer Tank: Intermediate Receiving Hopper ≈ 1.500 × 1.300 mm, Inclined Screw Conveyor: Length ≈ 4.000 mm, Elevation ≈ 45°, Discharging Material Toward Next Processing Stage. Technical Data (Approx.): Capacity: ≈ 250 – 400 kg/h (Depending On Polymer Type And Moisture), Main Drive: ≈ 90 kW, Auxiliary Motors: ≈ 2 × 7.5 kW. Overall Footprint: L 8.000 × W 3.000 × H 4.000 mm. - LOT 46

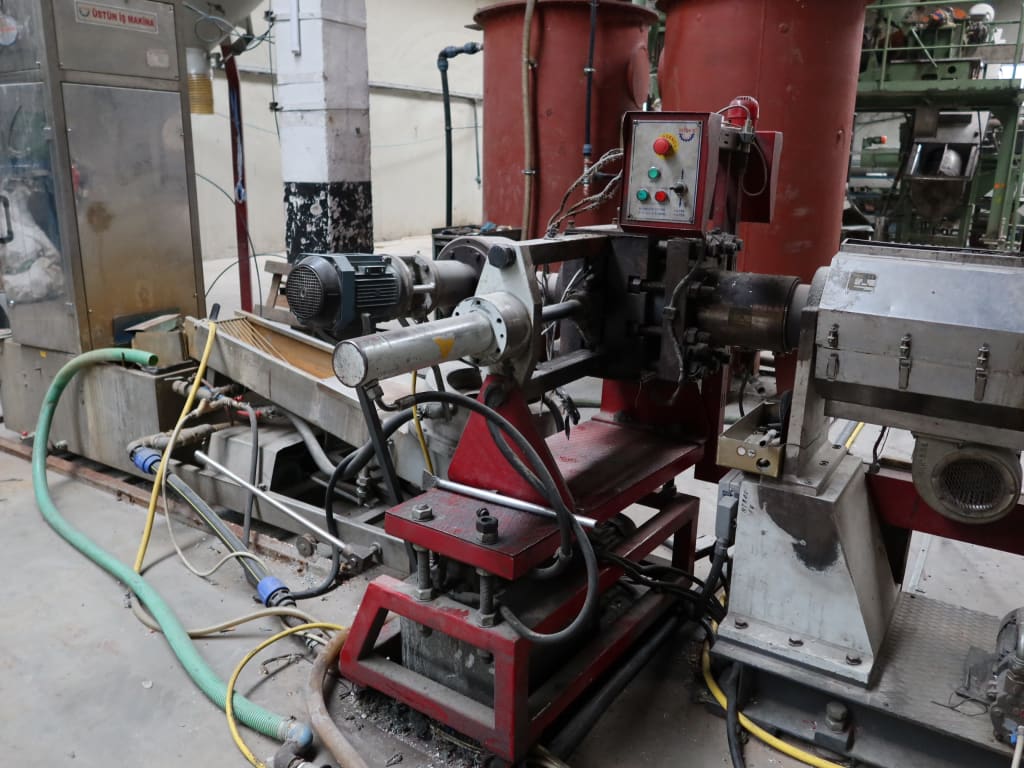

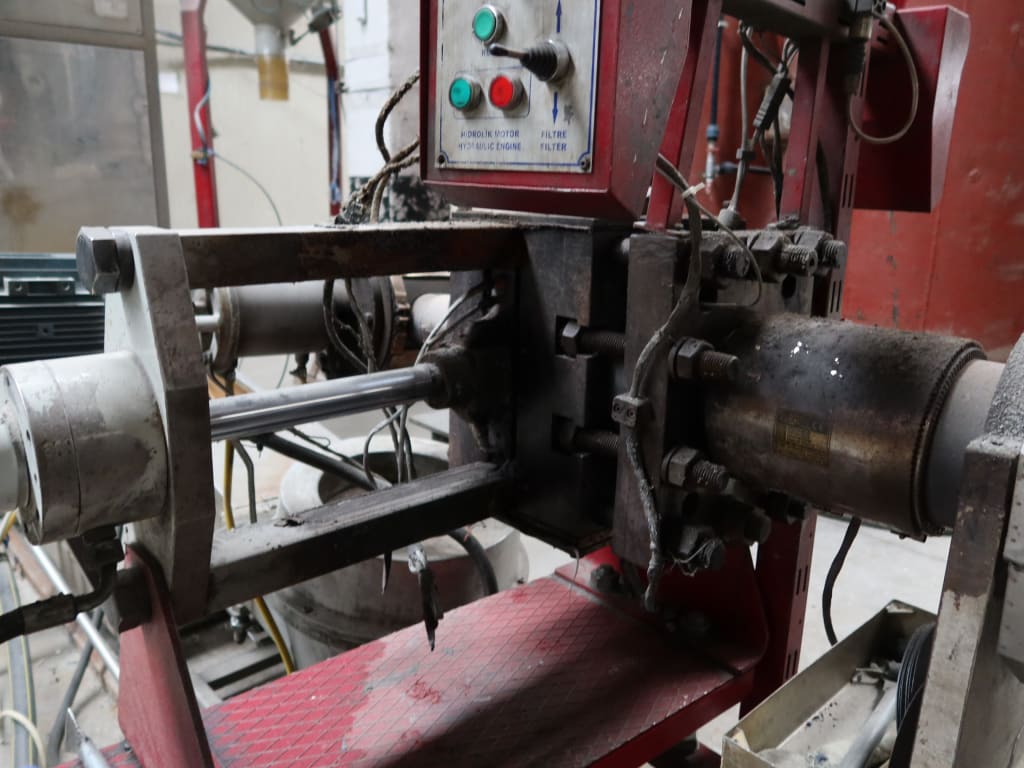

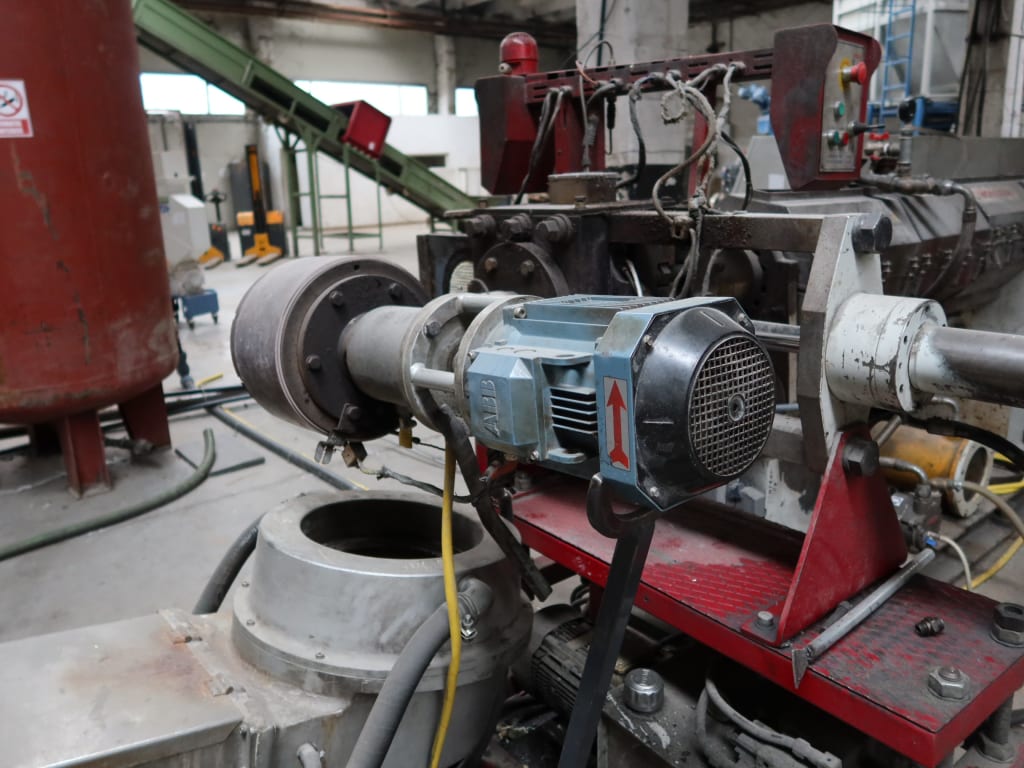

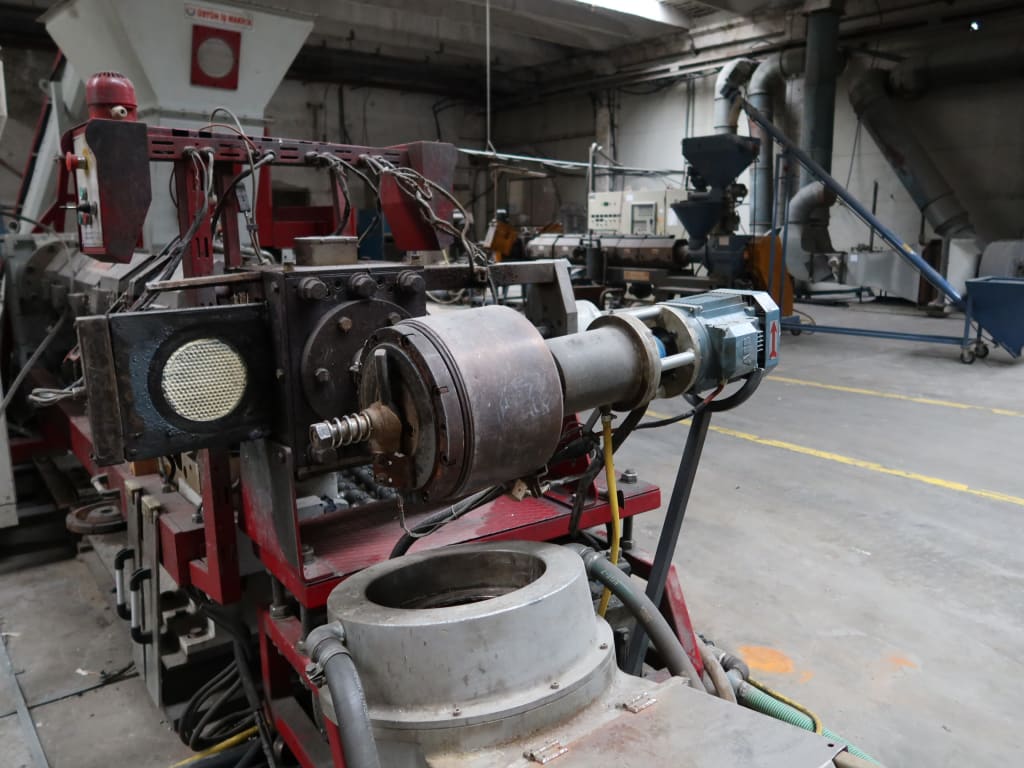

![site]()

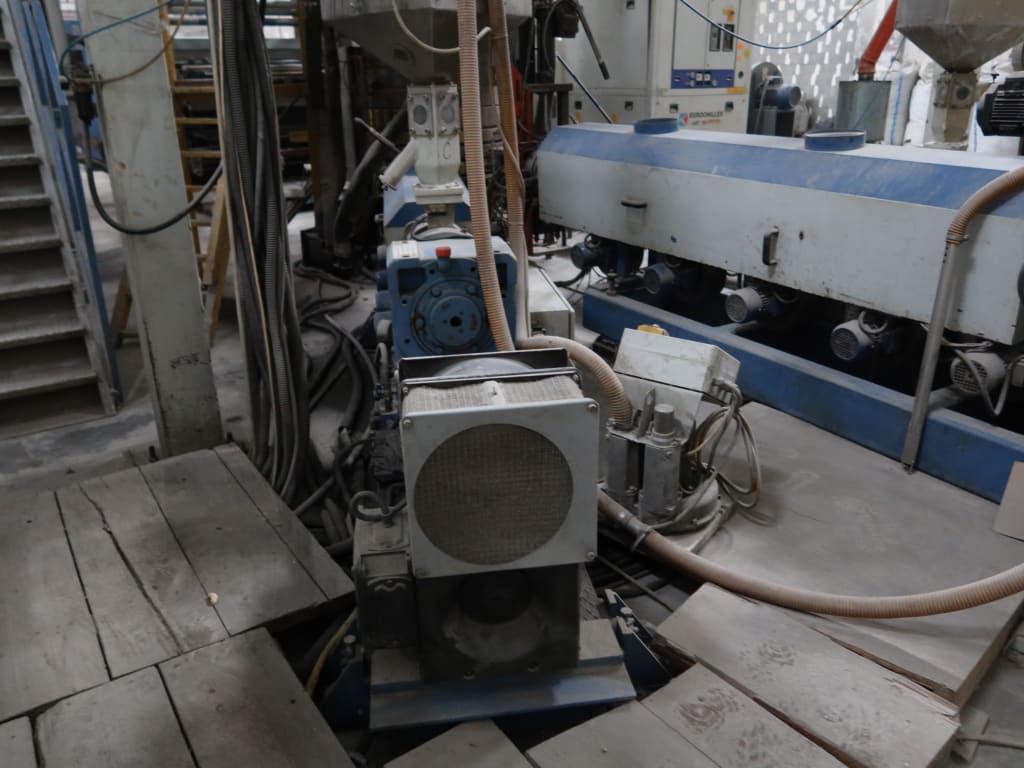

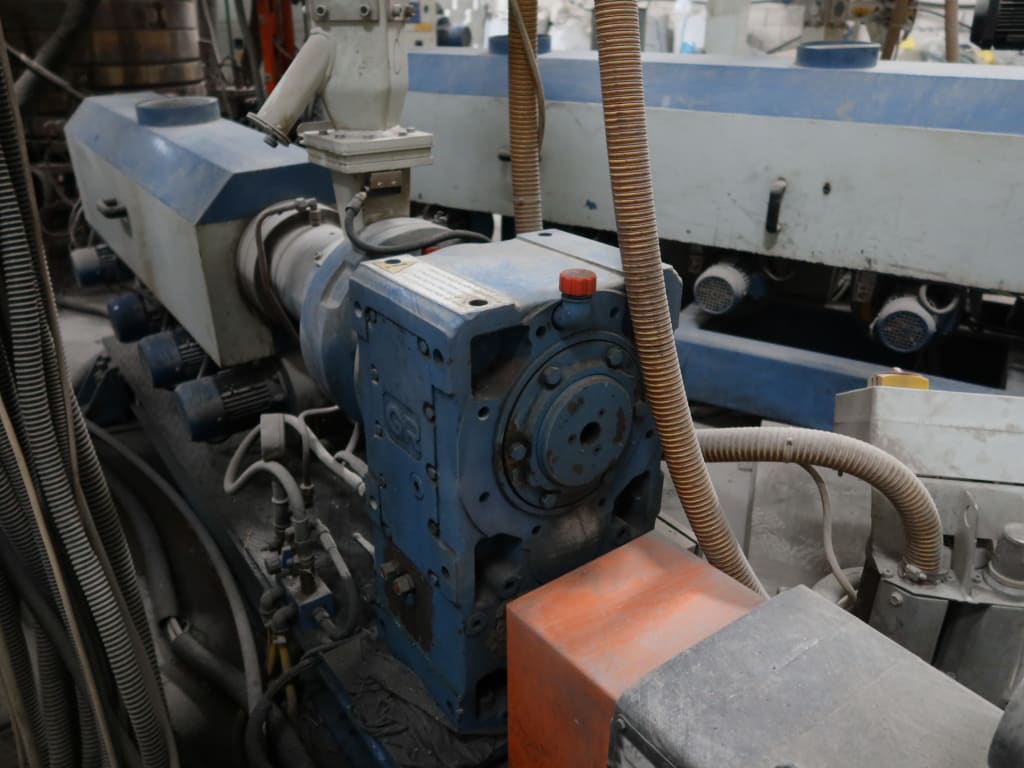

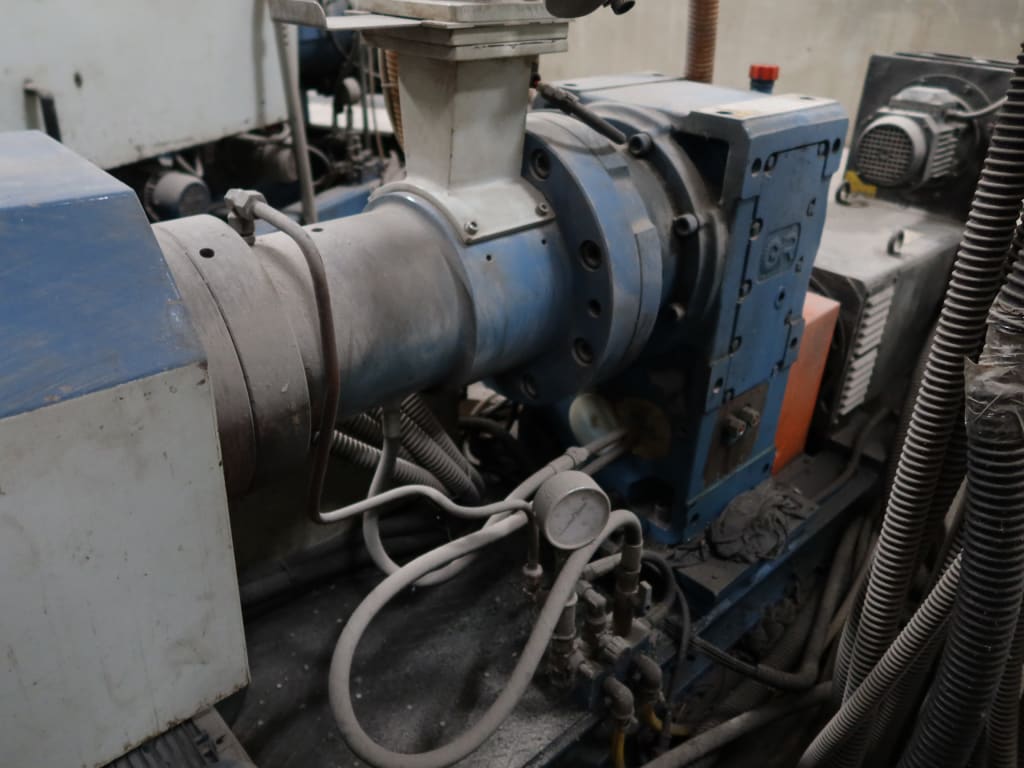

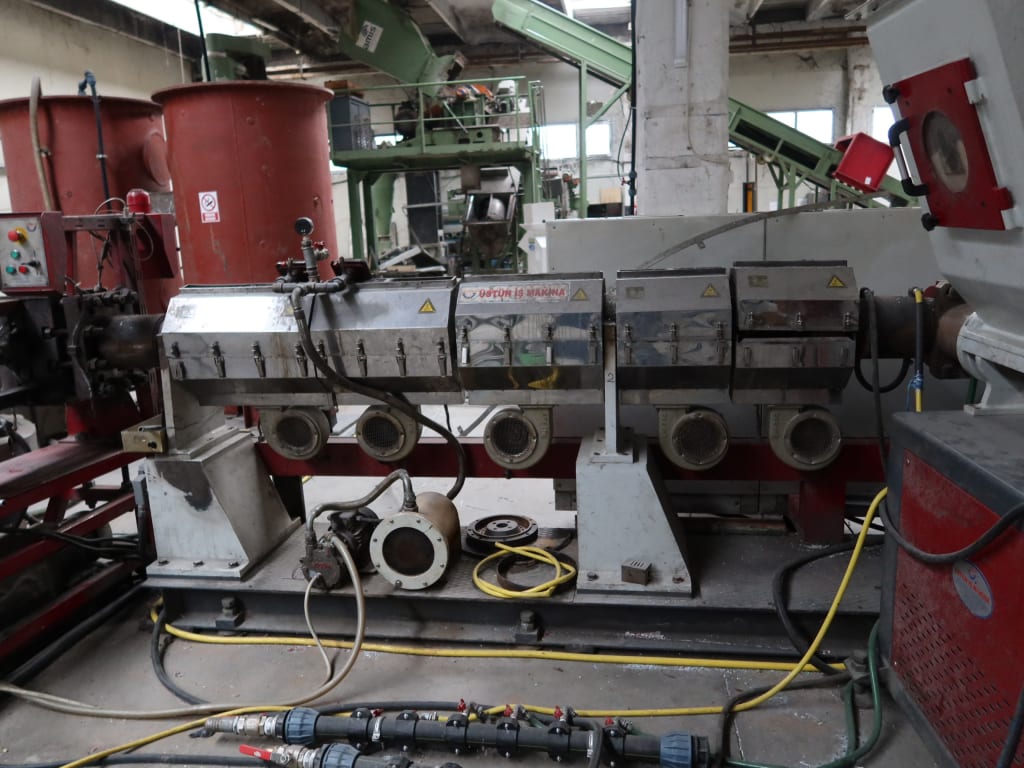

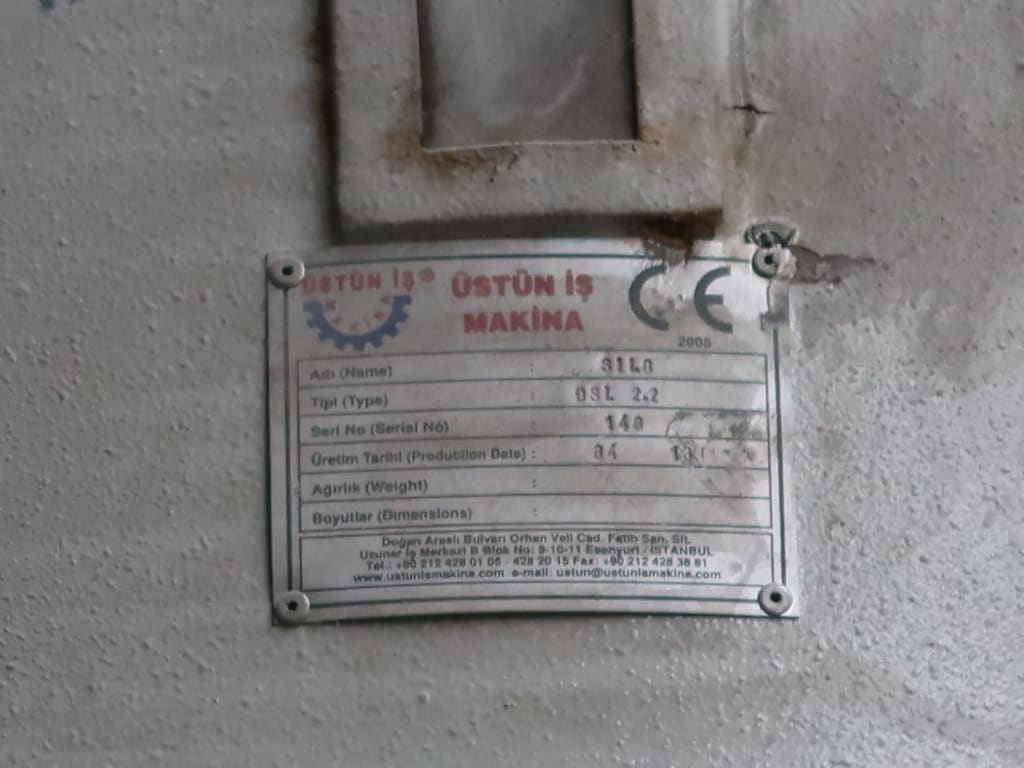

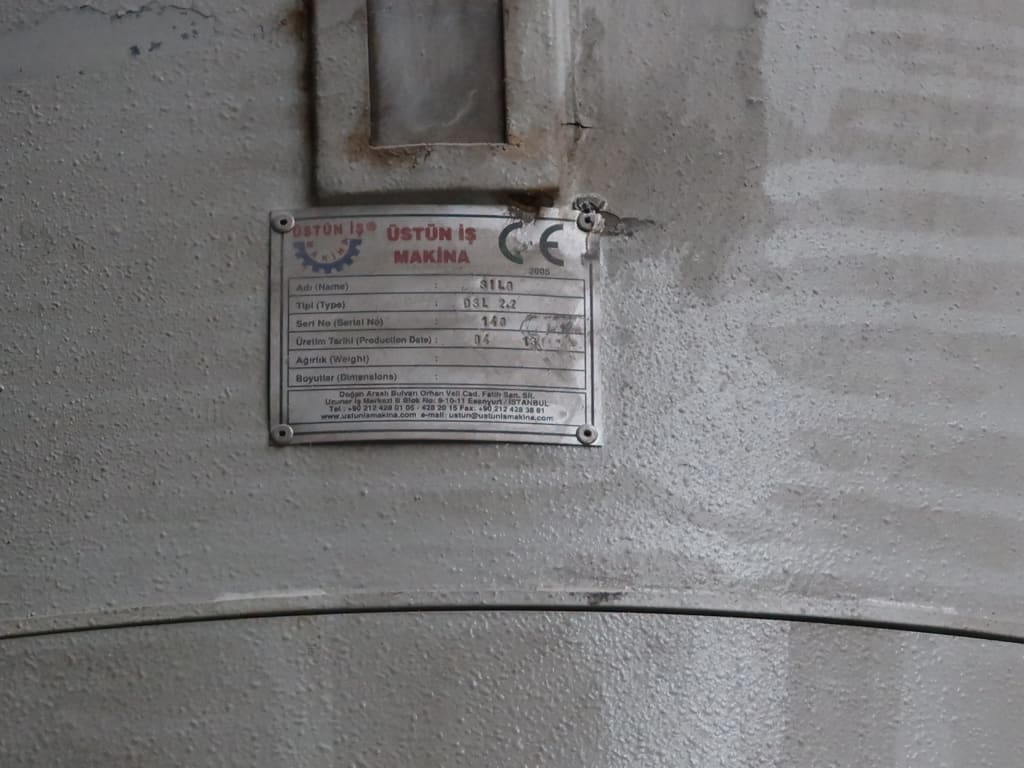

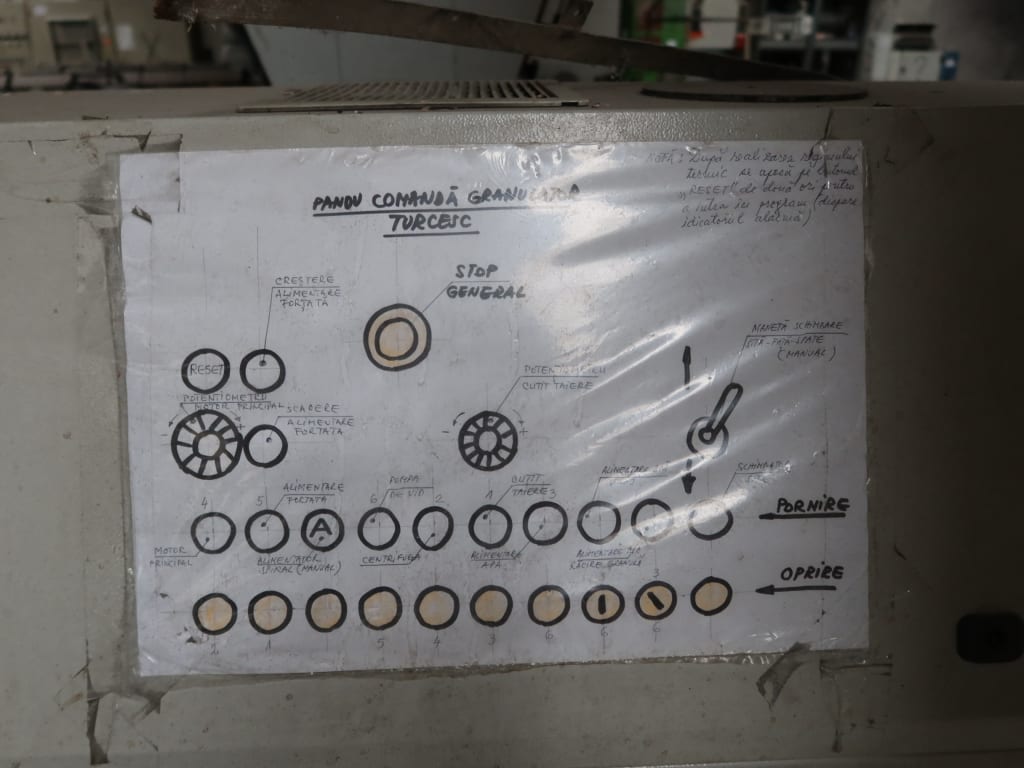

Ustun is Makina Complete Plastic Pelletizing Extrusion Line

Plastic Pelletizing / Regranulation Line (Single Screw Extruder), Extrusion Unit: Ustun İs Makina Single-Screw Extruder, Screw Ø ~100–110 mm, With Gearbox And Main Drive (Oil Cooling). Heating System: Multiple Heating Zones Equipped With Ser Rezistans Band Heaters. Die Head: Manual Screen Changer And Die Head With 5 mm Outlet Holes. Downstream & Auxiliary Equipment: Feeding Section: Feed Hopper (1.500 × 1.200 mm) With Screw Conveyor (~5.000 mm Long, 45° Inclination), Cooling And Pelletizing Section: Melt Exits Through Die Head And Is Cooled, Granules Are Separated, Air-Dried, And Conveyed Pneumatically, Final Silo: Üstün İş Makina Silo, Type OSL 2.2, Ø ~2.200 mm, Height ~3.500 mm (Year 2013), Auxiliary Tanks: Two Steel Water Tanks (Ø ~1.200 mm × H ~2.000 mm), Final Discharge: Big Bag Filling Station, Control System: Central Control Cabinet With Individual Temperature Zones And Process Monitoring. Technical Data (Approx.): Estimated Throughput: 300 – 500 kg/h (Depending On Polymer And Moisture). Overall Total Footprint: L 12.000 × W 3.000 × H 3.500 mm, Granule Diameter: Approx 5 mm - LOT 47

![site]()

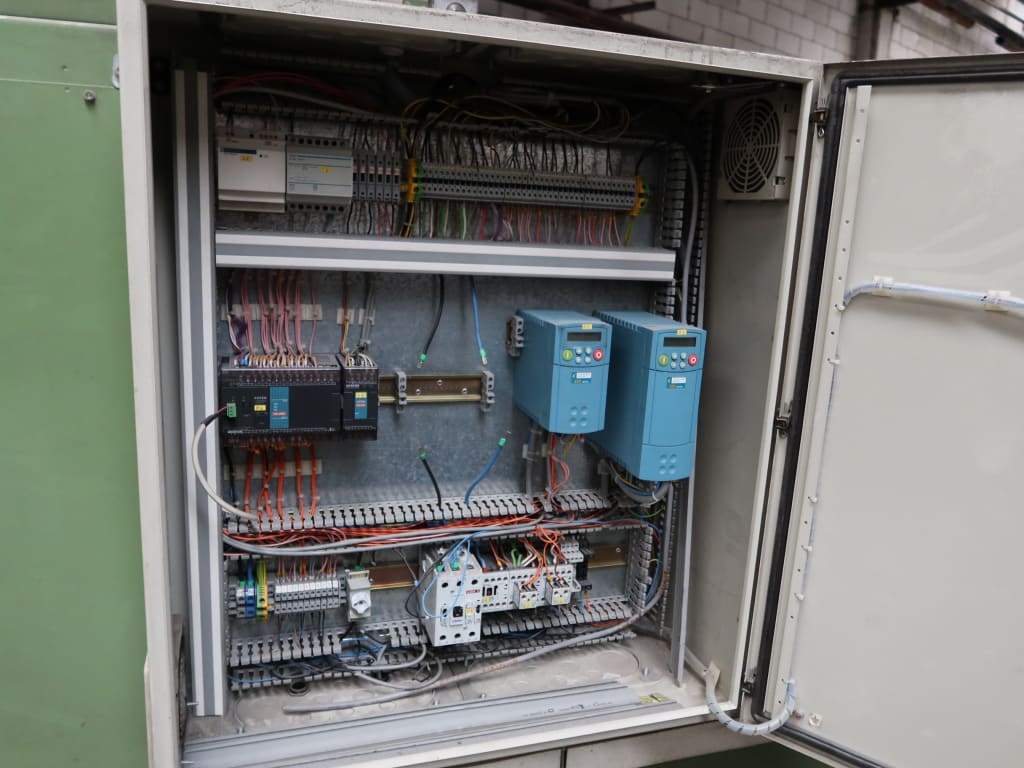

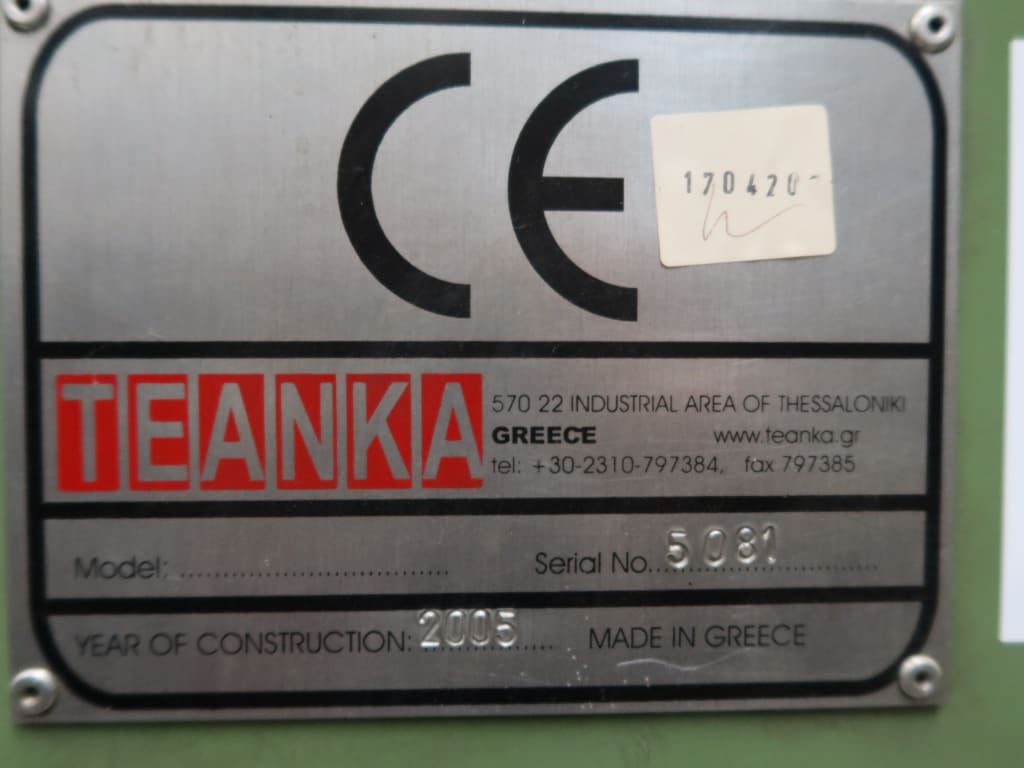

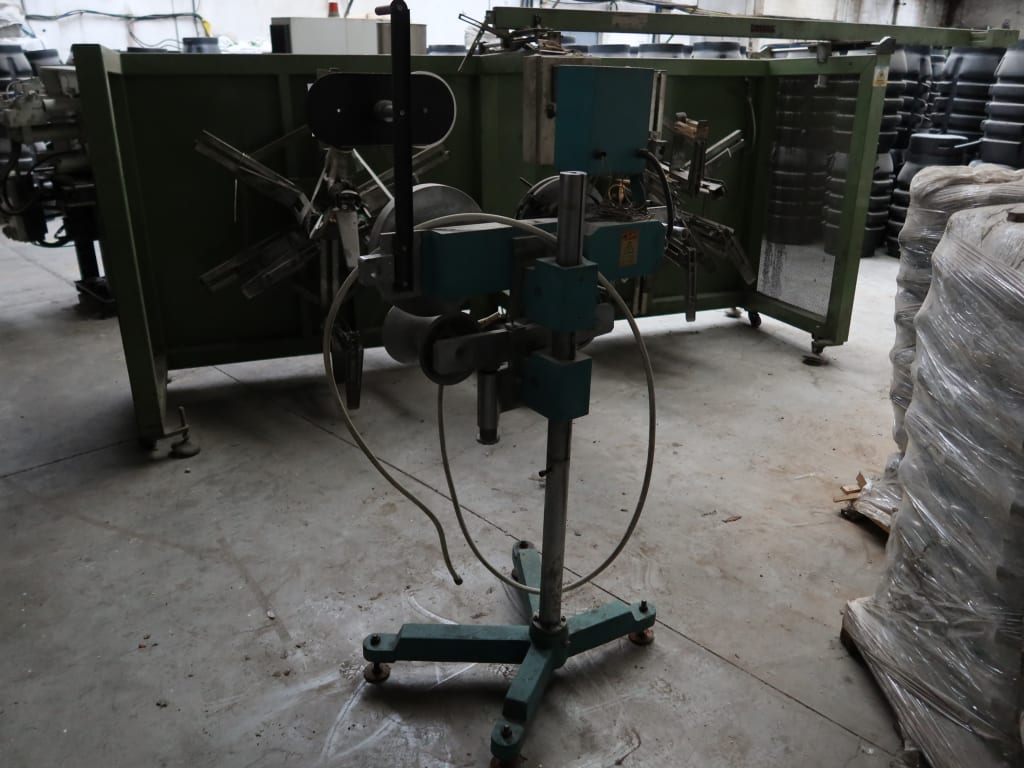

TEANKA Dual-Station Plastic Bobbin Winder (2005)

Slitting And Winding Unit (Dual Shaft), Comprising Of The Following Main Components, Winding Shafts: Two Independent Winding Shafts With Adjustable Arms. Control Panel: Central Electronic Control Panel With Digital Speed And Tension Control, Distribution: Traverse System For Even Winding Distribution, Structure: Frame-Mounted Structure On Castors For Mobility. Technical Data (Approx.): Approx. Total Weight: ~1.000 kg. Overall Dimensions: L 3.000 × W 1.200 × H 1.600 mm. - LOT 48

![site]()

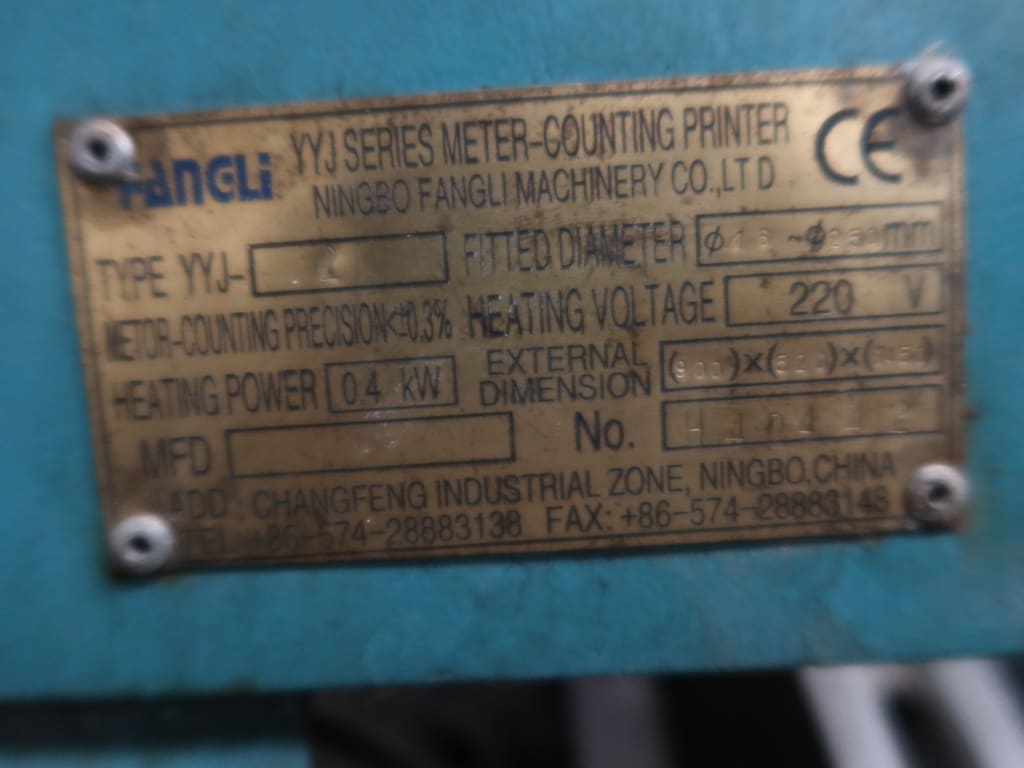

HANGLI, Type YYJ Meter, Counting and Printing Unit

Feed System: Mechanical Wheel Feed System With Two Measuring Rollers. Control Unit: Integrated Control And Heating Stand: Adjustable Height Stand On Four Feet, Certification: CE Marking. - LOT 50

![site]()

TRIA 60-42 XT Plastic Granulator/Grinder

Granulator/Grinder Machine (High Speed Rotor), Comprising Of The Following Main Components, Hopper Opening: 620 × 420 mm. Rotor Diameter: 360 mm. Blades: 3 Rotor + 2 Fixed (Optionally 5 + 2). Motor: 30 kW (Electro Adda EG200L-4). Downstream & Auxiliary Equipment: Feed: Manual Or Conveyor, Discharge: Pneumatic Outlet With Pipe Coupling, Noise Enclosure: Yes. Technical Data (Approx.): Production Rate: 400 – 600 kg/h, Approx. Weight: 1.910 kg, Rotor Speed: ≈ 1.800 rpm. Overall Dimensions: L 1.500 × W 1.200 × H 1.800 mm. Power Supply: 400 V / 690 V, IP55.

Essential Information

General Information

- Auction Dates

- Starts: 03 December 2025 at 08:00 GMTEnds: 25 February 2026 at 13:00 GMT

- Site Address

- Sat SaratelBistrita Nasaud427301Romania

- Viewing Days

- By Appointment OnlyViewings strictly by appointment only – Please contact Apex to make an appointment.

Fees & Payment

- Currency

- EUR

- Buyers Premium

- 18% or as specified on individual items

- Payment

General payment information

- A link to the invoice will be emailed to successful bidders

- Payment is due immediately on receipt of invoice

- All payments must be made in the currency on the invoice issued.

- Accepted forms of payment are bank transfer ONLY. We do NOT accept payment by card, cash or cheque

- NB: Please reference invoice number on bank transfer.

Goods

- Clearance days

- 04 March 2026 at 06:00 GMT - 18 March 2026 at 15:00 GMTCollections strictly by appointment only.

- General Collection Information

Collection

- Buyers are fully responsible for removal of items plus all transport and rigging charges.

- Items are only available for collection once the transfered funds have cleared, and a collection appointment has been booked.

- Buyers or third party movers must present an invoice to the on-site personnel when removing their items.

- Buyers must complete the removal of items within the clearance deadline. Normal removal hours are Monday to Friday, from 9am to 4pm (local time) unless otherwise stated.

- Contact and removal information will be emailed at the time invoices are issued.

- For a list of companies that can assist with removals and transportation please visit the Apex Auctions website's Service Providers section.

- Sales Contacts

- Auction informationMatei Radu AlexandruSplaiul Unirii 12, Cam 206

Muntenia Business Center

Bucuresti, sector 4

040035

Romania rmatei@apex-group.com+40735521661